Hello

Well these are some tough questions. I will do my best to advise.

Lower ball joints are part of the suspension and yes all these parts need to be in good working order for not only proper alignment, ride and stability but safety. A ball joint can separate and cause the wheel to fold under the wheel well. Not a safe thing.

As for the repair difficulty. Based off of your statement of the "inexperienced" part I would be concerned. Mainly due to the safety part. The truck on that side would have to be on jacks. That alone could crush or kill you if improperly done. During the work of removing the ball joint itself, I use a jack under the control arm to keep it from dropping too quickly. Again, a safety thing.

You would have to understand the working of certain tools and pullers. Some of these you can use from say, Auto Zone and return but again, you need to understand how the work for safety reasons. So is it difficult, not if you have basic understanding of various tools and safety of working the vehicle such as jacking etc and how the components work with each other so you know if you disconnect this what is it tied to and what can and will happen. I would not like to see you tackle this. You are a young lady, very intelligent I am sure and able to do many things. . .. . .but this one you need some mechanical experience.

We could provide some instructions. I have attached a few for your review to show you what I mean.

Another concern. You have a lot of good miles on the truck. It seems like a great vehicle. Please keep in the back of your mind if the lower ball joint is bad, it has been on there just as long as the other parts. . ..upper ball joint, shocks etc. It will be stronger than the other parts and may cause them to wear out more than they are and those will need to be repaired then another front end alignment.

If you don't get the front end aligned then you are just wearing out tires. . ..more costs.

My suggestion. You have 3 teen boys. I would check with a couple of the local, family owned auto shops to see if one or all three of your boys could one, assist with this and two, work there for FREE for a couple of days, cleaning up, assisting where needed etc to cut down on the cost of your repair. This would also help the boys understand many things also.

Another suggestion is to check several of the local churches. They will I am sure have auto mechanics that attend. Even though they may work say at a business they have these few tools and the experience to do this for you. I would suggest the same as above. You pay for parts and bring over some food and have the boys help out for several days either with auto work, yard clean up, mowing , painting, whatever it takes to reduce the cost.

Last suggestion. If you can find the above then I would replace the other things while there and it is torn apart. It is much easier and less costly in the long run. Replace the shocks, upper joints, tie rods etc. Then pay once for the front end alignment and you will be good for many more miles on the vehicle.

I hope t his helps.

Information on your car can be found at:

https://www.2carpros.com/kpages/auto_repair_manuals.htm

Brief Example

Removal

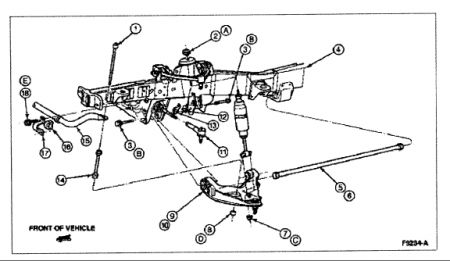

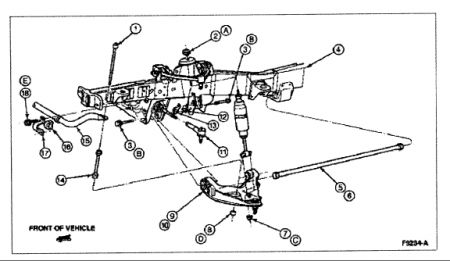

NOTE: Any time a front suspension lower arm is removed, the vehicle ride height must be checked. Place the steering wheel and steering system in the on-center position.

Raise vehicle on a hoist. Remove wheel and tire assembly.

Disconnect stabilizer bar link bolt from front suspension lower arm.

Remove the two nuts attaching the front shock absorber to the front suspension lower arm assembly.

NOTE: After removing the front shock absorber, support the front suspension arm bushing joint and front wheel spindle to prevent damage. Remove the upper nut and washer retaining the front shock absorber. Remove the front shock absorber.

Support the vehicle with safety stands under the jacking pads, and lower the hoist but maintain working room.

Remove torsion bar.

Loosen the two front suspension lower arm pivot bolts.

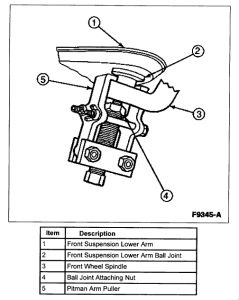

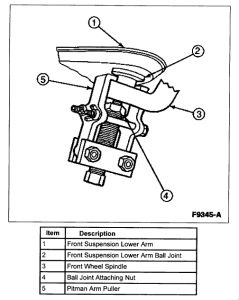

Remove the cotter pin and loosen, do not remove nut attaching the front suspension lower arm ball joint to the front wheel spindle.

Using Pitman Arm Puller T64P-3590-F, loosen the front suspension lower arm ball joint. Remove the puller tool.

Supporting front suspension lower arm with a jack, and remove the ball joint nut.

Raise the front suspension lower arm and disconnect front wheel spindle from the front suspension lower arm ball joint.

Remove the bolts and nuts retaining the front suspension lower arm to the front crossmember. Remove the front suspension lower arm.

Replace entire front suspension lower arm assembly-to-service bushings and ball joints.

Installation

Thursday, October 30th, 2008 AT 12:52 PM