TEST K: IMPROPER OIL PRESSURE WARNING OPERATION

Sedan & Wagon

Using mechanical gauge at pressure sensor port, test engine oil pressure. Pressure should be 35-65 psi (2.4-4.5 kg/cm2 ) at 2000 RPM (hot). If oil pressure is as specified, go to next step. If oil pressure is not as specified, repair engine as necessary.

Disconnect oil pressure switch connector C119. Measure resistance between terminal of oil pressure switch and ground with engine off, and then with engine running. Resistance with engine running should be more than 10 k/ohms. Resistance with engine off should be less than 5 ohms. If resistances are as specified, go to next step. If resistances are not as specified, replace oil pressure switch.

Turn ignition off. Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Remove low oil pressure warning light bulb. Check continuity between terminals of bulb. If continuity exists, go to next step. If continuity does not exist, replace low oil pressure warning light bulb.

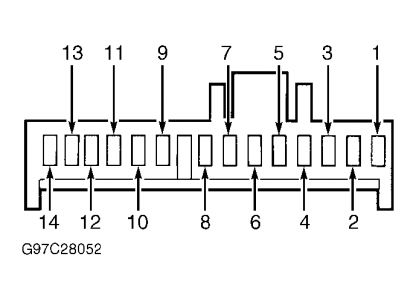

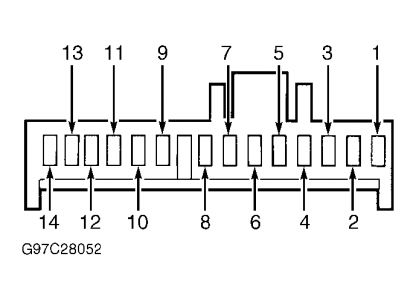

Disconnect instrument cluster connector C253. See Fig. 7 or Fig. 8 . Disconnect oil pressure switch connector C119. Measure resistance between instrument cluster harness connector C253 terminal No. 4 (Yellow/Red wire) and oil pressure switch connector. Resistance should be less than 5 ohms.

Measure resistance between ground and instrument cluster harness connector C253 terminal No. 4 (Yellow/Red wire). Resistance should be more than 10 k/ohms. If resistance in steps 4) and 5) is as specified, replace printed circuit and gauge contact clips. See PRINTED CIRCUIT under REMOVAL & INSTALLATION. If resistance is not as specified, repair open or short to ground in Yellow/Red wire between instrument cluster connector and oil pressure switch connector. See WIRING DIAGRAMS .

Friday, March 6th, 2009 AT 7:11 PM