Hi and thanks for using 2CarPros.

First, is the check engine light on while the engine is running? If so, have you had it scanned for codes?

If it is running that rich, there should be a code stored but that doesn't always happen. With that in mind, the most basic checks include checking the air filter box for blockages as well as the the induction tube between the air box and throttle body.

Next, a bad coolant temp sensor can be telling the computer it is extremely cold causing the computer to provide a rich mixture so the vehicle could run in the extreme temperatures. If you have a live data scanner, check the ECT reading. It should be very close to what the ambient temperature is with the engine cold.

Next, have you checked to confirm the catalytic converters aren't plugged?

Also, have you confirmed there isn't an issue with the fuel pressure? If the regulator has failed, fuel pressure can be extreme and cause a rich mixture. Additionally, if you check fuel pressure, confirm pressure drop off when the key is switch off. If it drops fast, you could have injectors leaking.

____________________________________

With that in mind, I am going to provide several different tests for you. All pictures correlate with the directions and I will title each.

___________________________________

Fuel pressure:

Here is a link that shows in general how it is done:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are the directions specific to your vehicle. Fuel pressure specs are included:

FUEL PUMP PRESSURE TEST

Use this test in conjunction with the Fuel Pump Capacity Test, Fuel Pressure Leak Down Test and Fuel Pump Amperage Test found elsewhere in this group.

Check Valve Operation: The fuel pump module contains a one-way check valve to prevent fuel flow back into the tank and to maintain fuel supply line pressure (engine warm) when pump is not operational. It is also used to keep the fuel supply line full of gasoline when pump is not operational. After the vehicle has cooled down, fuel pressure may drop to 0 psi (cold fluid contracts), but liquid gasoline will remain in fuel supply line between the check valve and fuel injectors. Fuel pressure that has dropped to 0 psi on a cooled down vehicle (engine OFF) is a normal condition. When the electric fuel pump is activated, fuel pressure should immediately (1 - 2 seconds) rise to specification.

The fuel system is equipped with a combination fuel filter / fuel pressure regulator. The fuel pressure regulator is not controlled by engine vacuum.

Warning: the fuel system is under constant fuel pressure even with the engine off. Before disconnecting fuel line at fuel rail, this pressure must be released. Refer to the fuel system pressure release procedure.

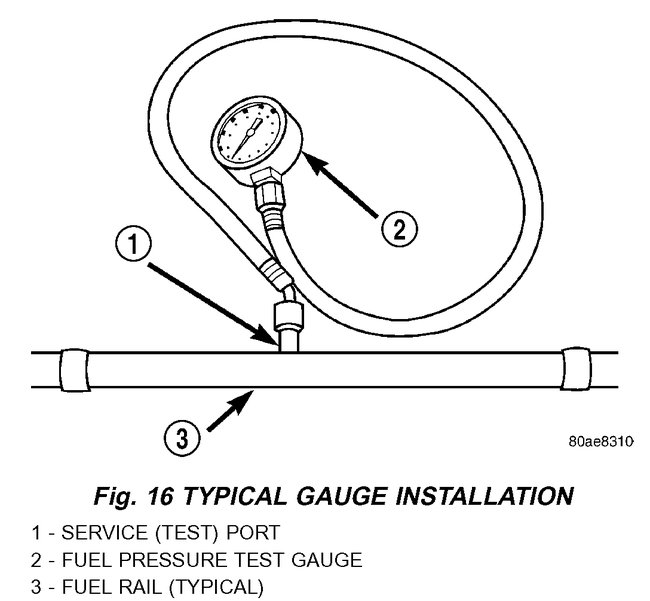

Fig. 16 Typical Gauge Installation

See Picture 1

1. Remove protective cap at fuel rail test port. Connect the 0 - 414 kPa (0 - 60 psi) fuel pressure gauge (from gauge set 5069) to test port pressure fitting on fuel rail (Fig. 16). The DRB(R) III Scan Tool along with the PEP module, the 500 psi pressure transducer, and the transducer-to-test port adapter may also be used in place of the fuel pressure gauge.

2. Start and warm engine and note pressure gauge reading. Fuel pressure should be 339 kPa ± 34 kPa (49.2 psi ± 5 psi) at idle.

3. If engine runs, but pressure is below 44.2 psi, check for a kinked fuel supply line somewhere between fuel rail and fuel pump module. If line is not kinked, but specifications for either the Fuel Pump Capacity, Fuel Pump Amperage or Fuel Pressure Leak Down Tests were not met, replace fuel pump module. Refer to Fuel Pump Module Removal/Installation.

4. If operating pressure is above 54.2 psi, electric fuel pump is OK, but fuel pressure regulator is defective. Replace fuel pump module. Refer to Fuel Pump Module Removal/Installation.

5. Install protective cap to fuel rail test port.

__________________________________________________________

Air Filter / Induction Tube

Here are a couple links that show how to replace the induction tube as well as air filter. Yours most likely is okay, so it doesn't need replaced. But this shows in general how to remove and replace so you can inspect.

https://www.2carpros.com/articles/replace-an-air-intake-boot

https://www.2carpros.com/articles/how-to-replace-a-car-air-filter

____________________________________________________________

Catalytic Converter:

Here are links that discuss the symptoms of a bad catalytic converter and how to test one:

https://www.2carpros.com/articles/bad-catalytic-converter-symptoms

https://www.2carpros.com/articles/how-to-test-a-catalytic-converter

__________________________________________________________

Engine Coolant Temp Sensor

The easiest way to do this is with a live data scanner.

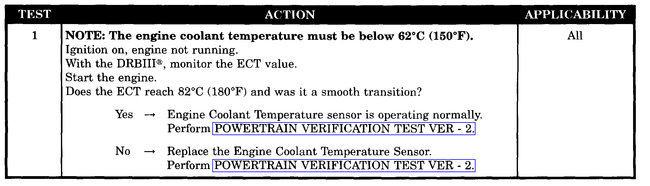

CHECKING THE ENGINE COOLANT TEMPERATURE SENSOR OPERATION

Test 1

See Pic 2

SYMPTOM

CHECKING THE ENGINE COOLANT TEMPERATURE SENSOR

POSSIBLE CAUSES

- ECT sensor operation

- ECT sensor

If you find the sensor is bad, here are the directions for replacement.

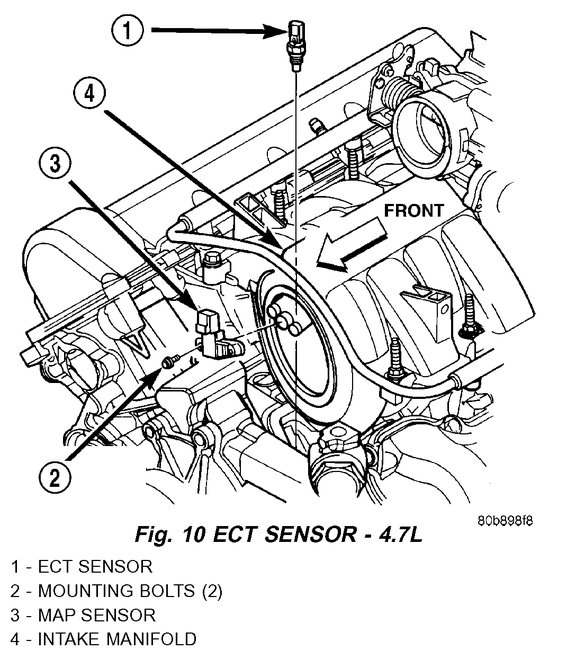

4.7L

Warning: hot, pressurized coolant can cause injury by scalding. Cooling system must be partially drained before removing the engine coolant temperature (ECT) sensor.

Picture 3

The Engine Coolant Temperature (ECT) sensor is located near the front of the intake manifold.

1. Partially drain the cooling system.

2. Disconnect the electrical connector from the ECT sensor.

3. Remove the sensor from the intake manifold.

Installation

4.7L

1. Apply thread sealant to the sensor threads.

2. Install the sensor to the engine.

3. Tighten the sensor to 11 Nm (8 ft. lbs.) torque.

4. Connect the electrical connector to the sensor.

5. Replace any lost engine coolant.

____________________________________________

If the check engine light is staying on, please provide the codes that were retrieved. Otherwise, it becomes a guessing game for me. There are several different things, as you can see, that can cause issues. These are only a few but I feel are the most common causes.

I don't know if you need this, but here is a quick video showing how a scanner is used to retrieve diagnostic trouble codes:

https://youtu.be/YV3TRZwer8k

Realizing most people don't own a scanner, keep in mind that often times a parts store will lend or rent one to you.

__________________________________

Let me know if any of this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

SPONSORED LINKS

Saturday, March 16th, 2019 AT 3:11 PM