Dunno where the ports at use below info to locate it

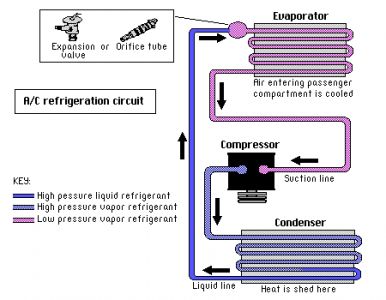

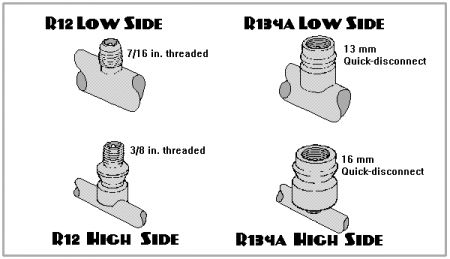

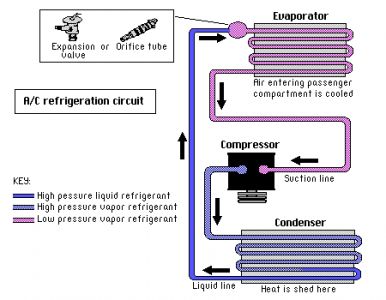

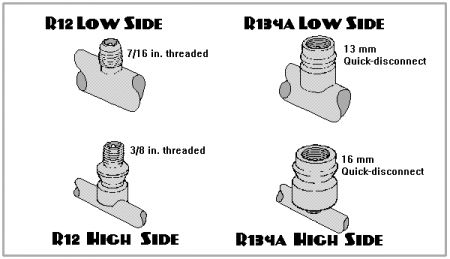

You need to locate the service fittings on the A/C system. There are two: a LOW side fitting and a HIGH side fitting. The LOW side fitting is usually located on the suction hose or line that goes from the accumulator to the compressor. The HIGH side fitting is located on the line that goes from the compressor to the condenser.

A retrofit can be done one of two ways. The first is to follow the vehicle manufacturer recommended retrofit procedure. This generally involves removing all the old mineral oil from the system, replacing the accumulator or receiver/dryer with one that contains X-7 desiccant, replacing O-rings (if required), installing or replacing a high pressure cutout switch (which many shops seem to forget), changing the orifice tube or expansion valve (if required), then adding the specified PAG oil and recharging the system with R134a. On some applications, installing a more efficient condenser may be recommended for improved cooling performance. After the modifications are made, the system is recharged to about 85 to 90% of its original capacity with R134a.

Federal law also requires the permanent installation of R134a fittings on the high and low service ports to reduce the chance of refrigerant cross-contamination the next time the vehicle is serviced. Labels must also be installed to identify the system has been converted to R134a.

The other approach to retrofit is the "quick and cheap" one. On many 1989 through 1993 vintage vehicles, R12 A/C systems can be converted by simply recovering any refrigerant that is still in the system, adding POE oil (which is compatible with both types of refrigerant), and recharging to 85 to 90% capacity with R134a.

A simple retrofit may therefore cost no more than a few cans of refrigerant and some compressor oil -- provided there's nothing else wrong with the A/C system. But simple low cost retrofits may not give the best cooling performance, and may not even be possible on some vehicles. Any compressor that has Viton seals is not a candidate for retrofit. This includes original equipment compressors such as Tecumseh HR980, some Keihin compressors and some Panasonic rotary valve style compressors on older Japanese cars. On these, the compressor must be replaced.

Compressor durability is also a concern with some vehicles. Because R134a raises compressor discharge pressures and increases the compressors work load, some lightweight compressors may not be rugged enough to tolerate R134a over the long haul. This applies to the Harrison DA6 and Ford FX-15 compressors. The Harrison DA6 can be replaced with a HD-6, HR-6 or HR-6HE compressor. The Ford FX-15 compressor can be replaced with a FS-10 compressor.

Regardless of which retrofit method is used, cooling performance will vary depending on the design of the system. As a rule, expect anywhere from a 3% to 15% decrease in cooling performance when an R12 system is converted to R134a. Systems with relatively large or efficient condensers will experience less of a drop in cooling performance with R134a than those with smaller or less efficient condensers.

SPONSORED LINKS

Saturday, June 27th, 2009 AT 8:26 PM