Wednesday, May 29th, 2024 AT 8:27 AM

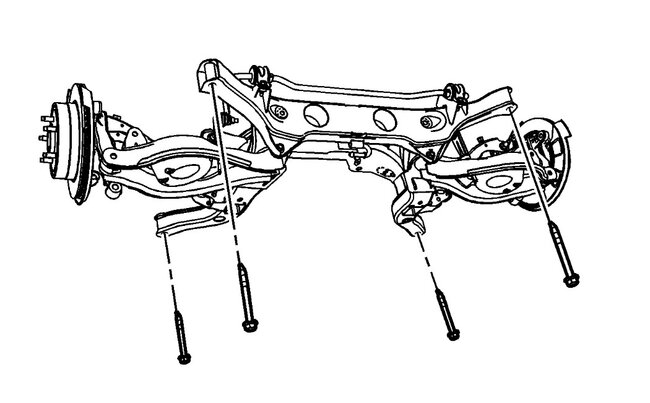

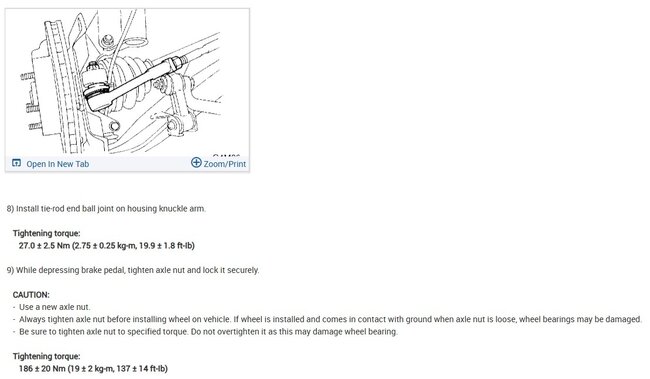

I had to bring a mobile mechanic in to try and free the axle I need to replace (front left), but he couldn't budge it - heat, air hammer, mallets - it's like it's welded together. Now, I need to either remove the entire assembly, and have a machine shop press it apart and rebuild, or buy new hub kit and knuckle, and have them press that together. I just replaced all 4 struts, and money is tight. What would you recommend as the best solution? And should I avoid re-using the existing bearings, after the pounding they just took?