Thanks Wrenchtech.

The thing to understand is it is extremely uncommon for a two-wire temperature sensor to read a wrong value because there's just one component in it. When they do read too high, it's more likely to be due to severe corrosion on the terminals.

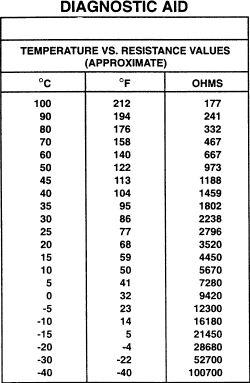

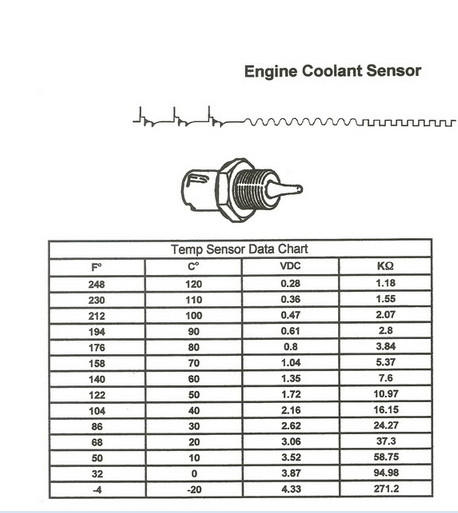

An instructor I used to work with forced his kids to memorize these resistance values, but that is a big waste of time. Not every sensor will measure exactly the same resistance at a given temperature. Their individual characteristics is part of what Engine Computers learn by comparing various sensor readings and operating conditions. What you need to look for is if you have something or an open circuit. Even an open circuit isn't common. If you DO get a resistance reading, you can compare it to the charts, but don't get excited if it isn't exactly what is listed.

A better test is to plug the sensor in, then back-probe through the rubber seal next to the signal wire, and measure the voltage. On all the cars I'm familiar with, the voltage will start near 4.2 to 4.5 volts, and go down as the engine warms up. It may get to around 2.0 to 2.5 volts well before full operating temperature is reached, then it may pop back up to, as I recall, around 3.5 volts, then go slowly down again.

That transition back to a higher voltage is due to the computer kicking in a different internal resistor to cause the sensor's reading to have more accuracy. As you can see, I know the theory better than the actual operation because we only test these circuits after the computer has already detected a problem, set a fault code, and we're just verifying it or looking for the cause.

SPONSORED LINKS

Friday, February 6th, 2015 AT 8:18 PM