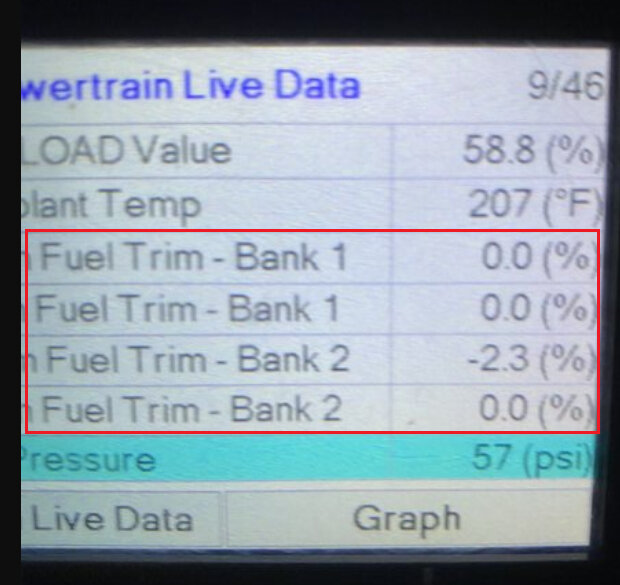

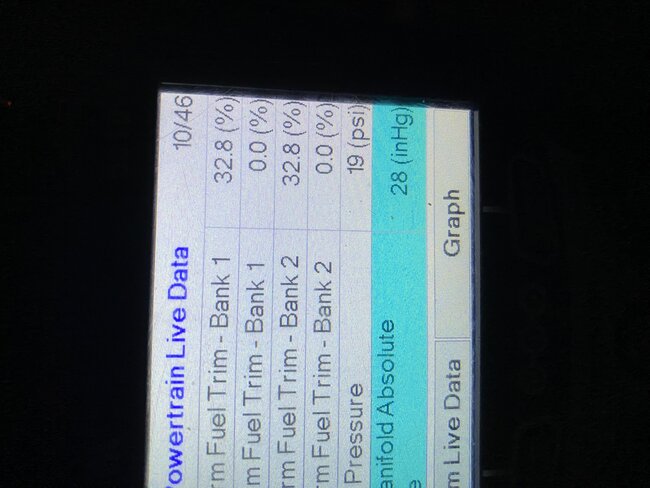

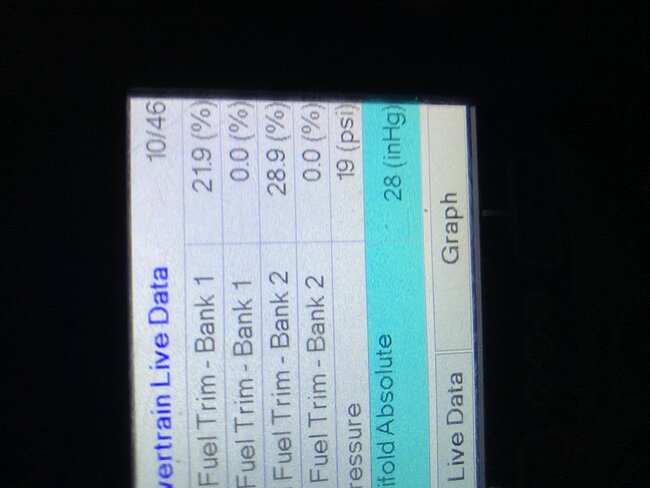

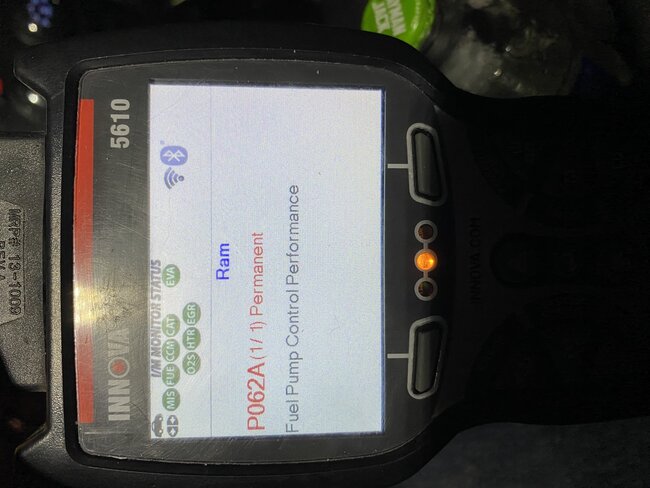

Is that the only code set today? Because we need to determine the variables here and come to a conclusion. The Pump module will do different things depending on the actual fault. For example, if the fuel pump is over drawing on current (which the module monitors) the Pump module will duty cycle to the pump very low to prevent the pump from completely failing, this may be why you are seeing a drop in fuel pressure at certain times.

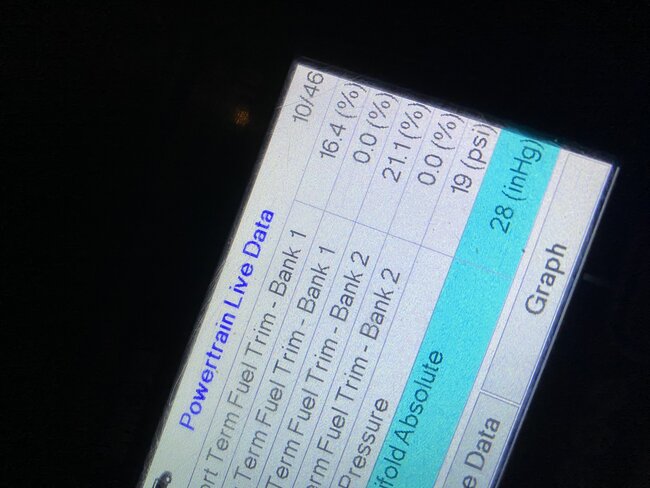

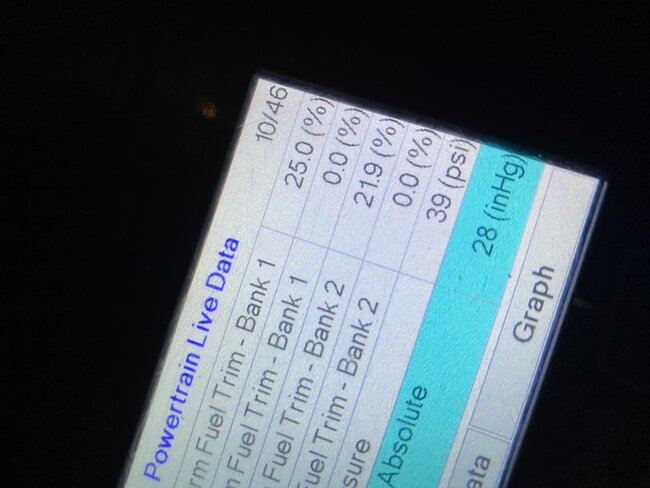

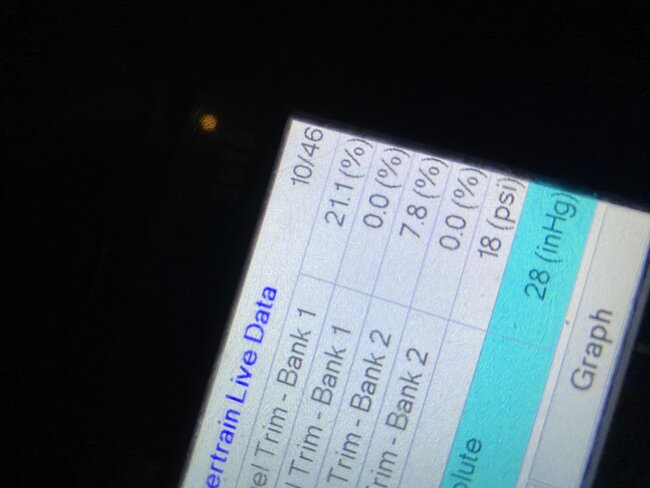

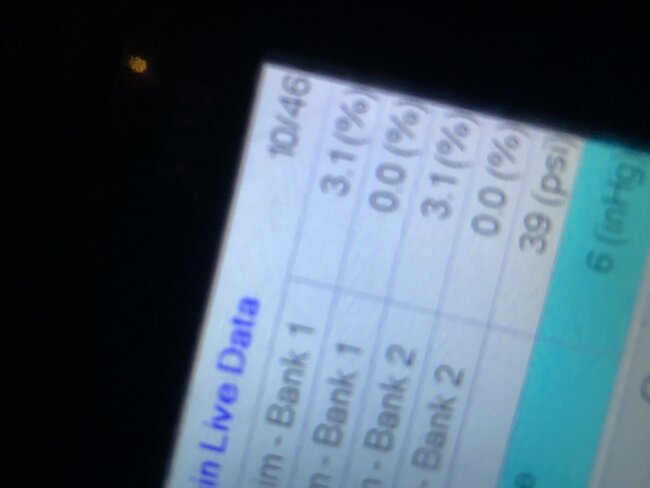

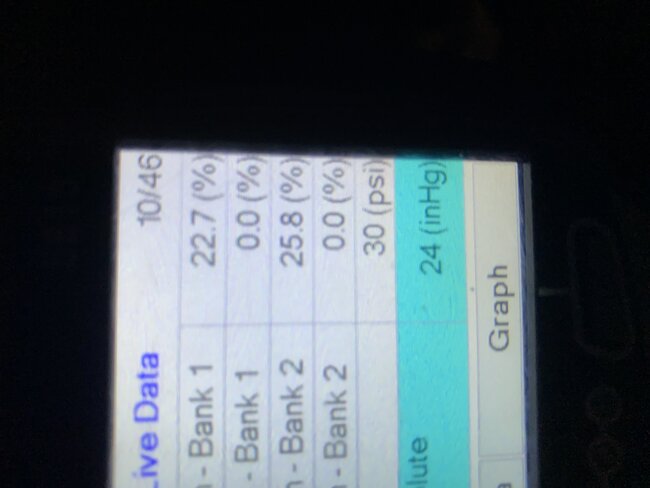

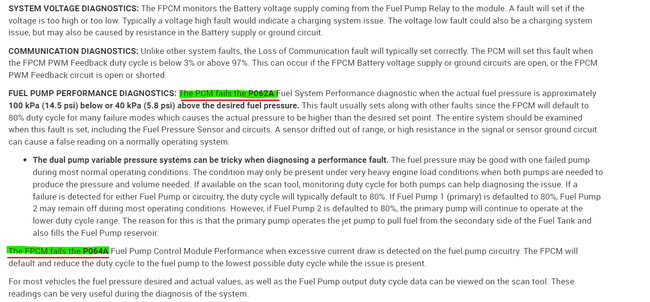

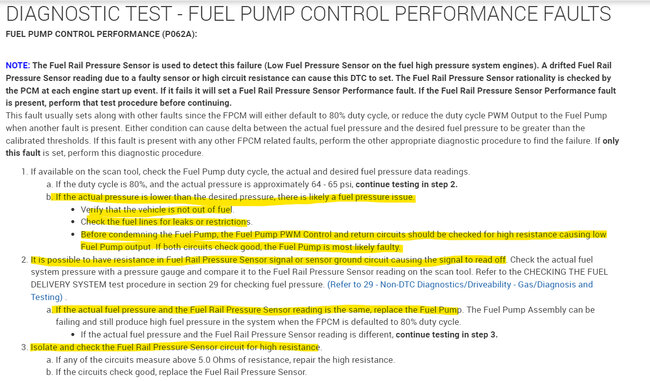

When there is low pressure detected, lower than the PCMs desired pressure (which there should be a data pid for Desired Fuel Pressure and Actual Fuel Pressure), there will usually be other faults detected and codes set. This will cause the pump module to default to 80% duty cycle, The fact that other codes are setting points to a wiring issue if those codes are staying active, but it looks like you only have the one code today.

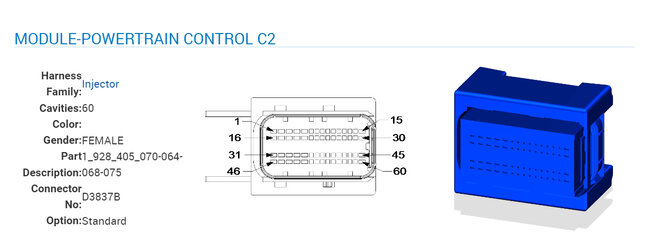

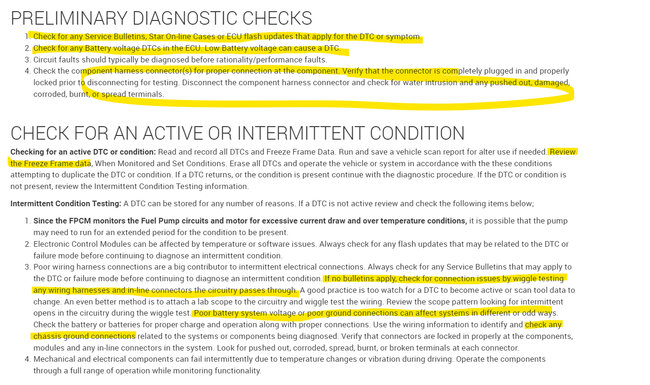

So going through more of the scan tools data pids after the vehicle has been driven and things are up to their highest temperatures, as well as starting to check the PCM connectors and checking the voltage readings at the pump module is the only way this is going to be diagnosed.

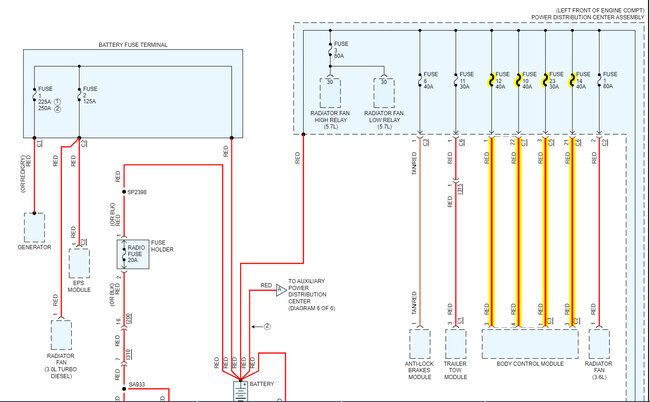

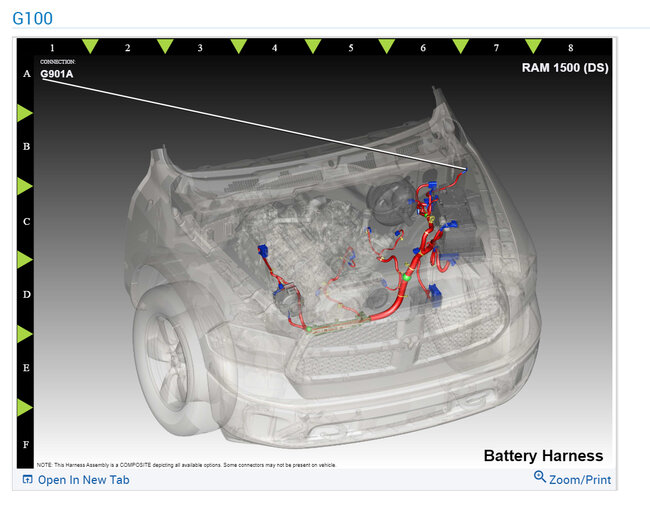

The entire system needs to checked. I would even go so far as to putting an amp clamp on the fuel pump main feed wire and see what its current draw is, But a lot of things need to be checked here before there is a major failure and the truck gets stuck on the side of the road.

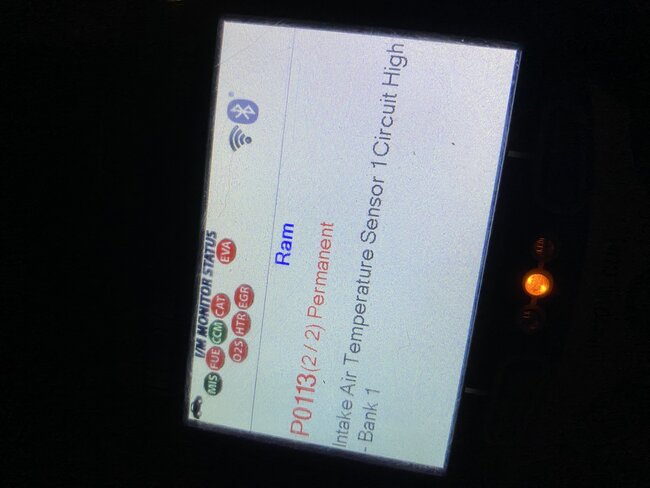

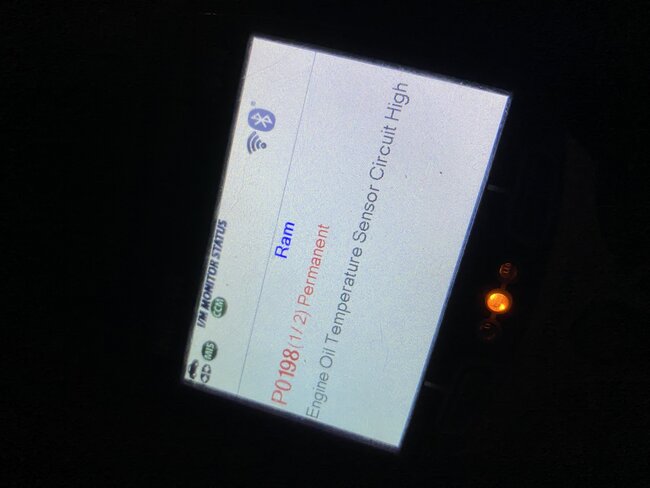

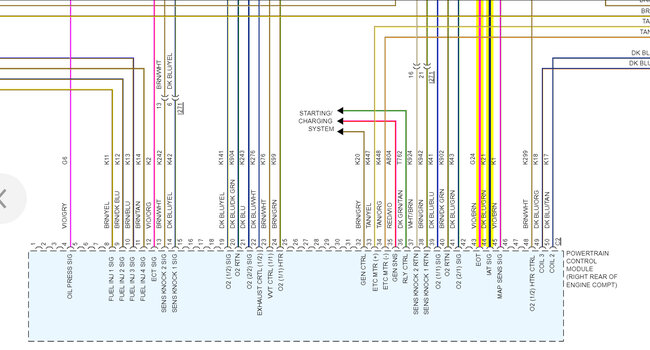

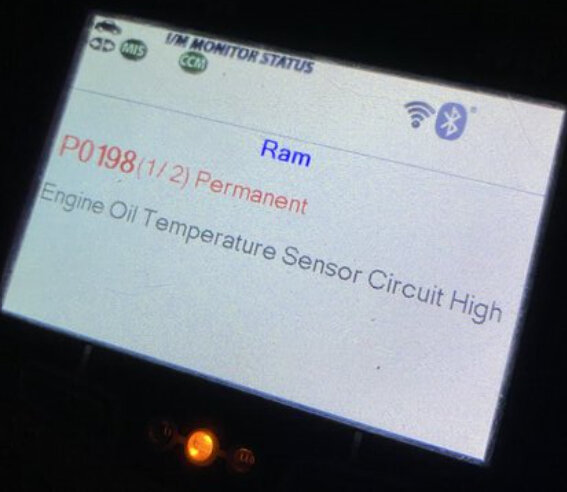

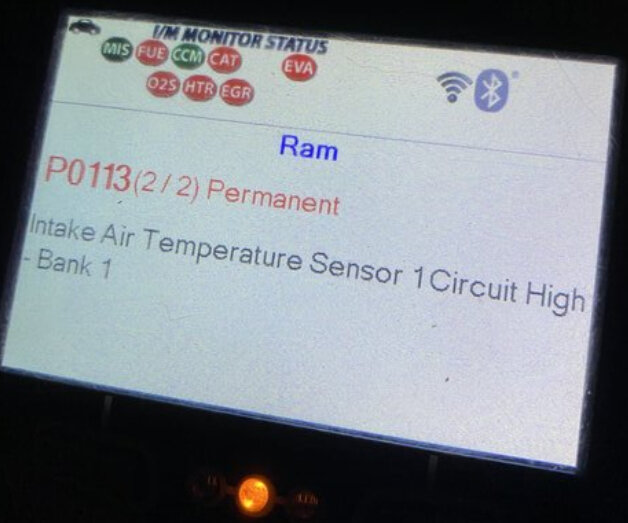

The other two codes that were set were indicating a possible short circuit to power or open sensor ground wire sending the voltage signal high. But if those codes are intermittent, the fuel system needs to be checked first.

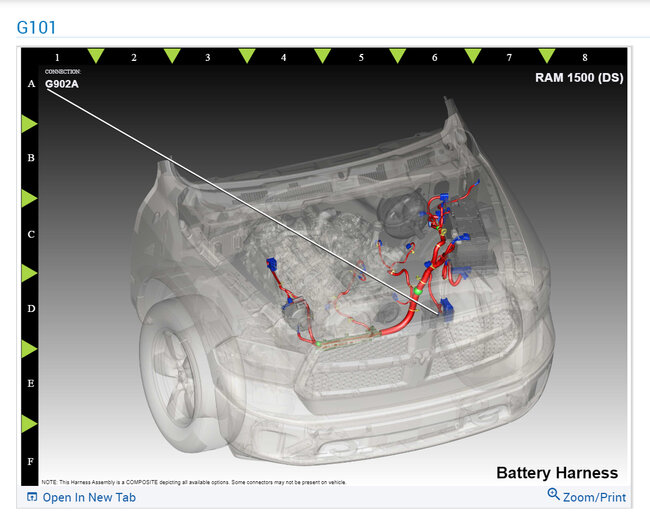

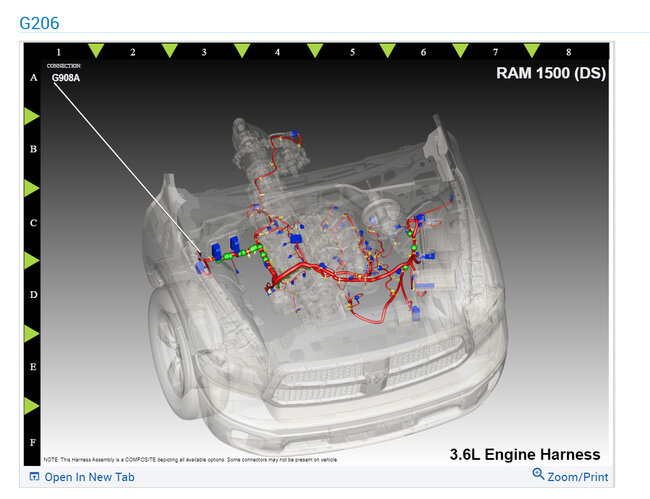

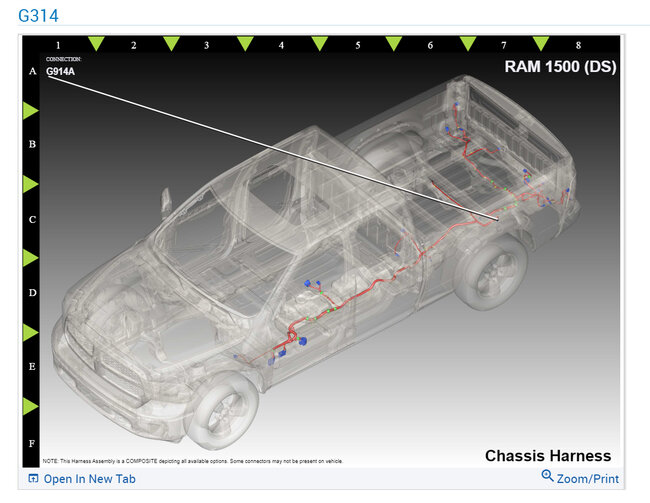

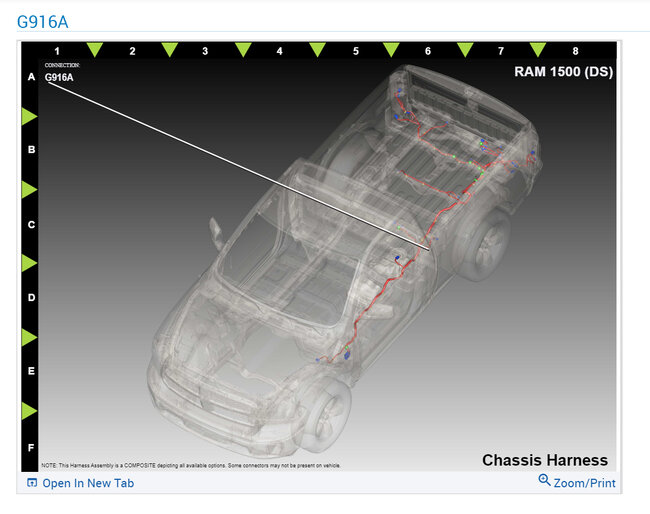

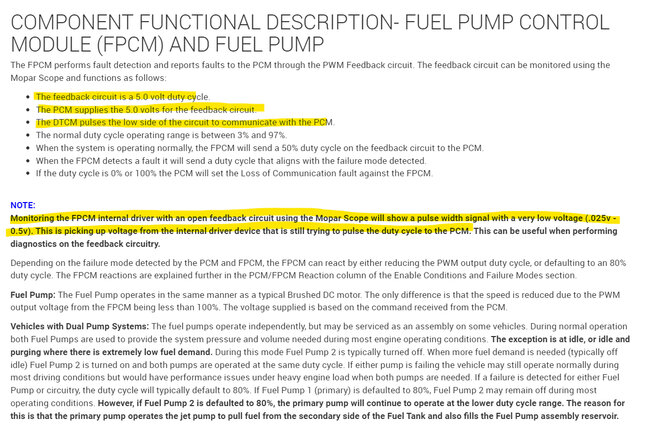

There is a whole list of tests to be done here with just the P062A code alone before something fails permanently. The diagnostics say what to expect, such as the feedback circuit being open, the voltage will read low 0.25 to 0.5volts. Normal is a 5.0volt circuit. Checking all the chassis grounds on the frame. It's all here.

Images (Click to make bigger)

Saturday, November 5th, 2022 AT 7:59 PM