I will keep the story short.

Blew head gasket and warped head, replaced both and also replaced spark plugs and leads and the car runs perfect no leaking and does not miss or any power loss.

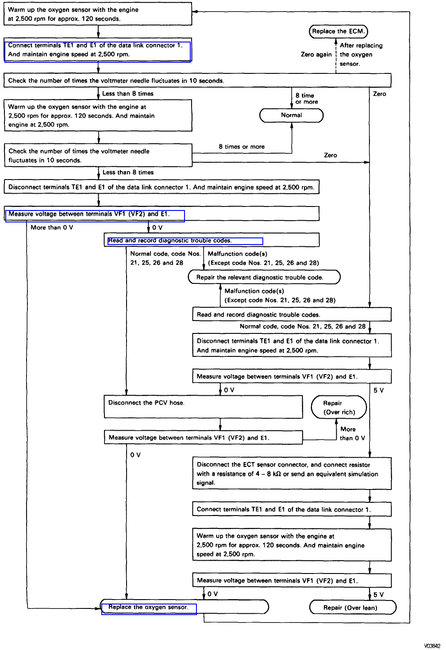

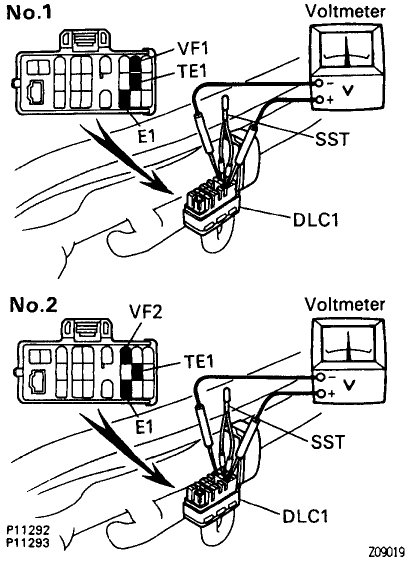

Check engine light with code 25 engine running lean happens each time I drive it and warms up and each time I turn the car off and turn the car on again and start driving for about a minute or so the code comes back on, but still no missing or no power loss. Cleaned the o2 sensors overnight in petrol then drove the car for about an hour to get replacement o2 sensors. Removed the old o2 sensors and one is black while the other looks normal. Drove it home and took the new o2 sensors out to check em and the same problem one looks normal and the other one is black.

Still getting the running lean code so decided to check all vacuum lines for air leaks and did not discover any leaks. Just hunting for some advice please, because I am close to hitting the wall and running out of ideas.

Tuesday, September 26th, 2017 AT 2:26 AM