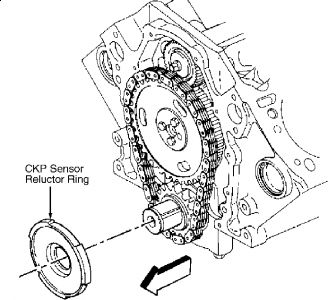

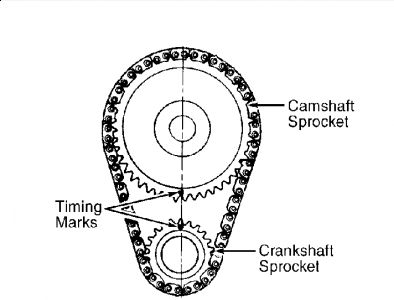

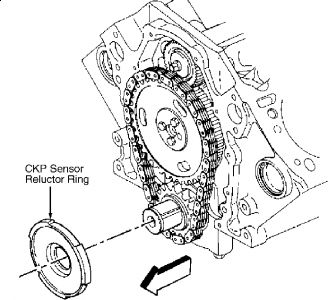

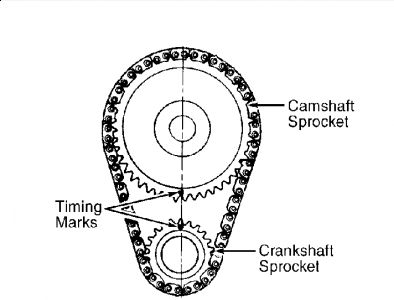

Installation 1. Install Woodruff key in crankshaft (if removed). Using Crankshaft Sprocket Installer (J-5590), install crankshaft sprocket. Install camshaft sprocket and timing chain. Ensure timing marks on sprockets are aligned. See Fig. 5 . 2. Balance shaft drive gear, driven gear and gear bolt are serviced as a set. Install and tighten camshaft sprocket bolts to specification. See TORQUE SPECIFICATIONS table. 3. Install and align CKP sensor reluctor ring. See Fig. 4 . Install NEW front cover and gasket. Tighten front cover bolts to specification. See TORQUE SPECIFICATIONS table. 4. Install CKP sensor. Tighten CKP sensor holddown bolt to specification. See TORQUE SPECIFICATIONS table. 5. Apply RTV sealant to Woodruff keyway in crankshaft balancer. Using Damper Puller/Installer (J-23523-F), install crankshaft balancer. Tighten fasteners to specification. See TORQUE SPECIFICATIONS table. To install remaining components, reverse removal procedure. Fig. 4: Removing/Installing CKP Sensor Reluctor Ring Courtesy of GENERAL MOTORS CORP. Fig. 5: Aligning Timing Marks Courtesy of GENERAL MOTORS CORP. CAUTION: Failure to properly align CKP sensor reluctor ring may result in component damage and could affect system performance. CKP sensor reluctor ring is shaped like a dish. Dished side of CKP sensor reluctor ring must face engine front cover. NOTE: DO NOT reinstall original composite front cover. Always install a NEW front cover. Reinstalling original front cover can lead to oil leaks. CAUTION: Ensure CKP sensor is fully seated and held stationary in bore of front cover upon installation. A CKP sensor that is not fully seated may result in erratic engine operation. Page 1 of 1 8/5/2009

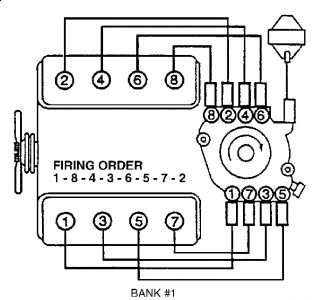

First get engine to top dead center with compression gauge or compression whistle , next rotate harmonic balancer so the slot is matched between the little numbs on the timing cover. Next remove rotor button on the distributor now the number eight will be on top of a square hole under rotor button .You need to move that over to the little pointer on the inside of the outer part of the distributor it has a pointer with a number 6 on it (it should be on the passenger side ). Lift up distributor and move the number 8 on the center part till you are over or just before the little pointer on the outer edge of the plastic distributor. If not all the way down in, the oil pump is not clocked in properly hold down on the distributor and have some one click the starter make sure you unplug the coil though and just a couple clicks holding dowm on the rotor top of distributor that should bring it in place. Put back together and try to start the vehicle and then if it stats do the timing set up for syc through the scanner at 1500 rpm move distributor till you see +- 2degrees . Thn tighten your distributor and test drive .

Wednesday, August 5th, 2009 AT 3:41 PM