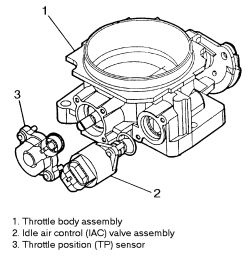

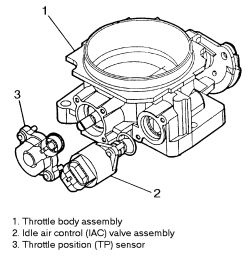

We are getting there. The next thing to check (if I haven't already mentioned it) is the idle air control motor. Basically, it keeps the idle steady by allowing air into the throttle body when the throttle plate closes. It is located on the throttle body. Here is a picture of it:

Now, two things can go bad with it. The valve can stick not allowing proper air flow, or it can short internally. Here are the directions I was able to dig up for checking it:

Disengage the IAC electrical connector.

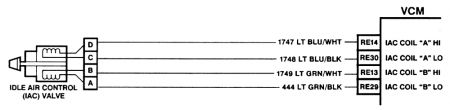

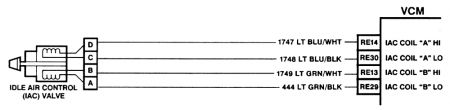

Using an ohmmeter, measure the resistance between IAC terminals A and B. Next measure the resistance between terminals C and D.

Verify that the resistance between both sets of IAC terminals is 20-80 ohms. If the resistance is not as specified, the IAC may be faulty.

Measure the resistance between IAC terminals B and C. Next measure the resistance between terminals A and D.

Verify that the resistance between both sets of IAC terminals is infinite. If the resistance is not infinite, the IAC may be faulty.

Also, with a small mirror, inspect IAC air inlet passage and pintle for debris. Clean as necessary, as this can cause IAC malfunction.

Here is the wiring schematic for the IAC so you can see what wires to test:

The images and information I provided are for 1988 to 1998. Let me know what you find. Chances are the IAC is good (electrically) but there is something causing the pintle to stick.

I'll keep my fingers crossed and hope this helps.

Joe

Tuesday, October 19th, 2010 AT 7:19 AM