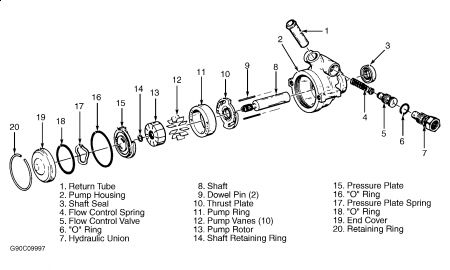

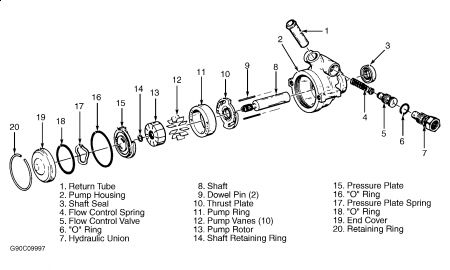

POWER STEERING PUMP (CB SERIES)

Disassembly

Remove hydraulic union fitting (or VES actuator) from pump.

Remove "O" ring, flow control valve assembly and flow control spring.

Insert punch in access hole, and remove end cover retaining ring.

Press gently on pulley end of shaft to remove end cover, "O" ring, pressure plate spring and pressure plate.

Remove shaft subassembly consisting of remaining components.

Disassemble subassembly, noting component location for reassembly reference. Cut shaft seal with a small chisel.

Remove and discard shaft seal.

Inspection

Inspect pump ring, rotor, vanes, thrust plate, pressure plate and shaft for scoring, pitting or chatter marks. Replace worn or damaged parts

Reassembly

Lubricate new shaft seal, "O" rings and all other components with power steering fluid. Drive new seal into housing with suitable socket. Assemble shaft subassembly with components in original locations. Ensure counterbore in center of pump rotor faces pump pulley.

Install shaft subassembly. Install remaining components. Press end cover in far enough to snap retaining ring into place. Install flow control valve assembly and related components. Tighten hydraulic union to specification

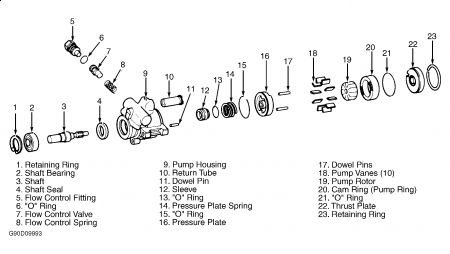

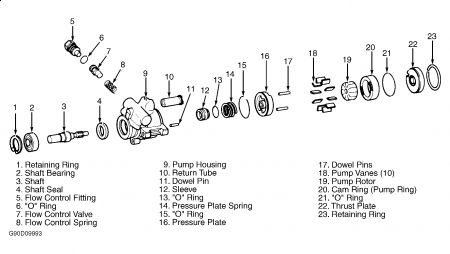

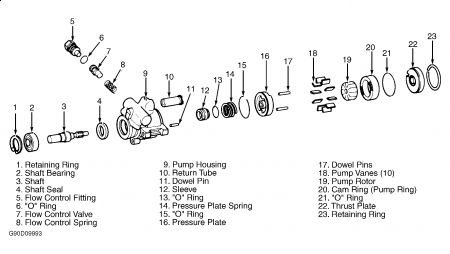

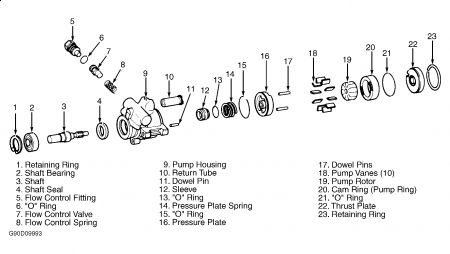

POWER STEERING PUMP (TC SERIES)

NOTE:Pump is not serviceable on Seville.

Disassembly

Remove pump pulley.

Remove shaft bearing retaining ring.

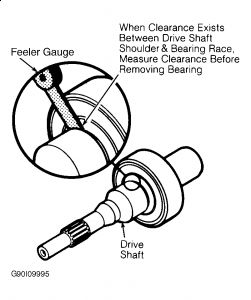

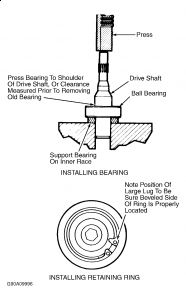

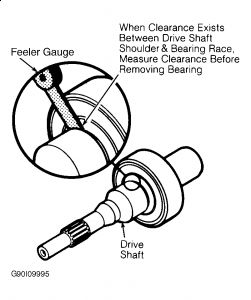

Pull shaft and bearing assembly out of pump. If removing bearing from shaft, measure and record clearance (if any) between shaft shoulder and bearing inner race.

Pry shaft seal from housing.

Remove flow control fitting from pump.

Remove "O" ring, flow control valve assembly and flow control spring.

Insert small punch in access hole, and remove thrust plate retaining ring. Using a press and 5/8" piece of bar stock, press against pressure plate hub until thrust plate is removed. Remove "O" ring, pump ring, pump rotor, vanes and 2 dowel pins.

Remove pressure plate using press (if necessary). Remove "O" ring from pressure plate. Remove dowel pin from housing. Remove "O" ring from sleeve. Working from pulley side of housing, drive out sleeve with a punch.

Reassembly

Press new sleeve assembly into housing. Install new, lubricated "O" ring into groove in sleeve. Install dowel pin into housing. Install pressure plate spring. Install new, lubricated "O" ring into groove in pressure plate.

Mark spot on top of pressure plate directly over dowel pin hole in plate to help align hole with dowel pin. Install pressure plate into housing, ensuring pin engages hole in pressure plate. Install 2 pump ring dowel pins.

Install pump rotor with counterbore (larger diameter of center bore) facing pulley end of housing. Insert pump vanes into rotor slots. With identification marks on pump ring facing upward, install pump ring over dowel pins. Install new, lubricated "O" ring into housing groove.

Install thrust plate, ensuring dimples in thrust plate align with mounting holes in housing, and thrust plate holes engage pump ring dowel pins. Press thrust plate into housing far enough to install retaining ring. Install retaining ring with opening centered on mounting boss nearest access hole.

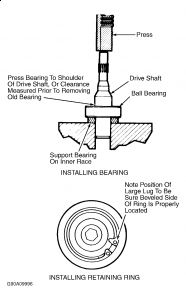

Press shaft bearing onto shaft until clearance between inner race and shoulder is same as clearance recorded during removal.

Slide shaft and bearing assembly into housing, rotating assembly to align splines of shaft and rotor. Install bearing retaining ring with beveled side down, indicated by position of large lug on ring. Install pulley on pump

Thursday, June 18th, 2009 AT 6:16 AM