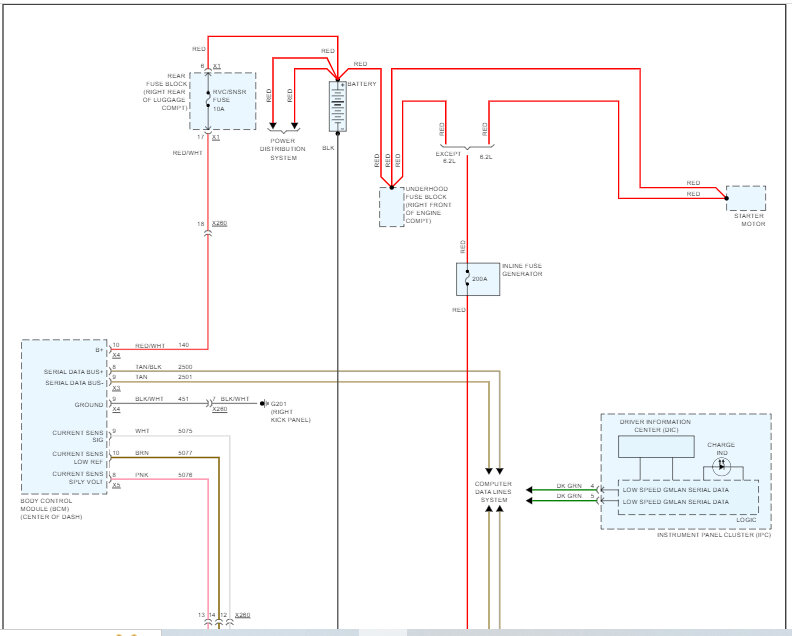

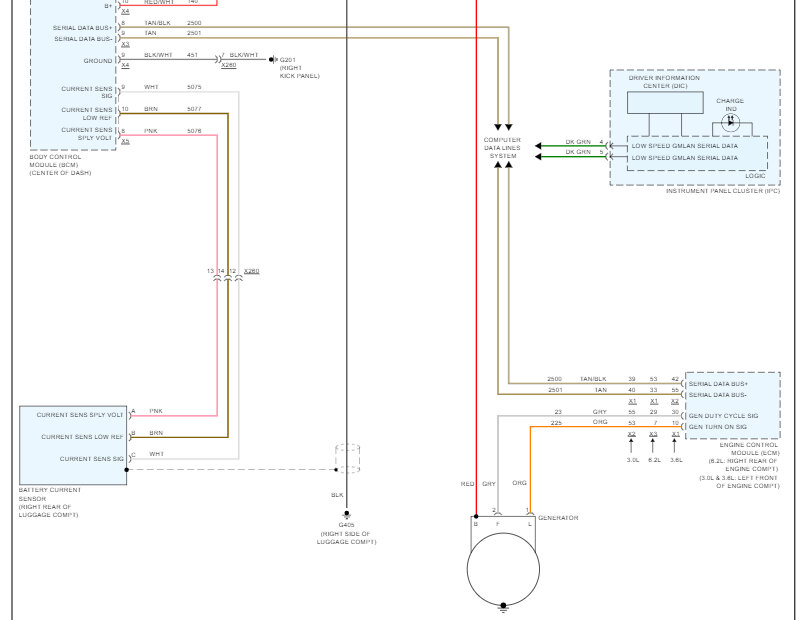

I'm going to start you off in a different direction. All the warning lights are involved with multiple computer modules, and those are very intolerant of low system voltage. Consider those as clues, hints, or observations, but not symptoms of failing computers. I'm pretty sure those lights will turn off once the charging system is repaired. To start, you may want to check out this article:

https://www.2carpros.com/articles/how-to-check-a-car-alternator

Basically all you can do is check the battery's voltage while the engine is running. It should be between 13.75 to 14.75 volts, depending on which text book you read. If that is what you find, you're not done. Passing that test only means it is okay to continue on with the rest of the tests, but that requires a professional load tester. I strongly discourage people from removing a generator from the engine and hauling it to an auto parts store for off-car testing. The professional load test includes all the wiring on the car, along with the battery, in the tests. You'll need to visit a mechanic for this, but the test is very quick and painless. It takes longer to connect the three cables than it does to perform the tests.

The first thing that will show up is the charging voltage test. That's the one you can do yourself with an inexpensive digital voltmeter. Next will be the "full-load output" test. It looks like the only generator offered in your model was a 140-amp unit. That's pretty big; about double what was standard in the '80s. It will never be asked to develop that much current except during the full-load test. At that time the mechanic is going to find either very close to 140 amps, or very close to exactly one third of that. This part of the test is only run for a couple of seconds; just long enough to see the value. This is the test that can fail, even though that first voltage test came out okay.

Now to back up a little, GM had, in my opinion, the world's second-best generator design through the 1986 model year, then they redesigned them for the '87 model year and really messed it up. They, by far, are responsible for the most failures, and repeat failures. Due to their design, they develop huge, harmful voltage spikes that can destroy the internal diodes and voltage regulator and can interfere with computer sensor signals. It's the battery's job to dampen and absorb those spikes, but as they age and the lead flakes off the plates, they lose their ability to do that. It is not uncommon to go through four to six replacement generators in the life of the vehicle. To reduce the number of those repeat failures, always replace the battery at the same time, unless it is less than about two years old. You already did step two with the new battery, but I suspect there's one failed diode of the six inside the generator. This is where you will lose exactly two-thirds of the generator's output current capacity. A 140-amp unit will only be able to develop around 45 amps during the test, and less during normal driving. That isn't enough to run the four dozen computers on your car, plus all the lights, radio, heater fan, etc., and to keep the battery charged. The battery will have to make up the difference as it slowly runs down over days or weeks. This agrees with your very first sentence, and in fact, the first half of your post. If it hasn't totally failed, the old battery can work fine in an '86 or older model.

Another test is for "ripple voltage". AC generators, ("alternator" is actually a term copyrighted by Chrysler, but we all know what we're talking about), develop three-phase output, similar to that used in factories, because it is very efficient. When one of the six diodes fails, one of those three phases is lost, but it cuts output current producing capacity by two thirds, as I mentioned. During the time that output voltage is missing, system voltage drops significantly. That momentary lower voltage, compared to normal charging system voltage, is called "ripple voltage". It is measured by all professional charging system testers. The difference is in how it is displayed. Those testers that can make printouts of the results will show ripple voltage as an actual voltage. Most testers just show it as "low" or "high" on a relative bar chart with multiple lights. High ripple voltage is the second symptom of a failed diode. On older cars it can even cause an irritating whine on AM radio.

We would never risk angering a customer by trying to rebuild or repair a generator, although we would do that for our own cars. If the repair goes sour, we have only ourselves to blame. Trouble is this '87 and newer model is virtually impossible to take apart without damaging some parts, and then there's no easy way to test the parts, so we have to replace them all. There are rebuild kits available, but they're so expensive, it isn't worth the trouble. My reason for pointing this out is when it comes to buying a professionally rebuilt generator with a warranty, be sure to check all the prices. My friend is on his fourth replacement on his GMC. For the second one, he found one with a 2-year warranty for $200.00, and one from the same store but a different rebuilder with a lifetime warranty for $150.00. Less expensive and a better warranty. Cost him nothing but his time for the last two replacements.

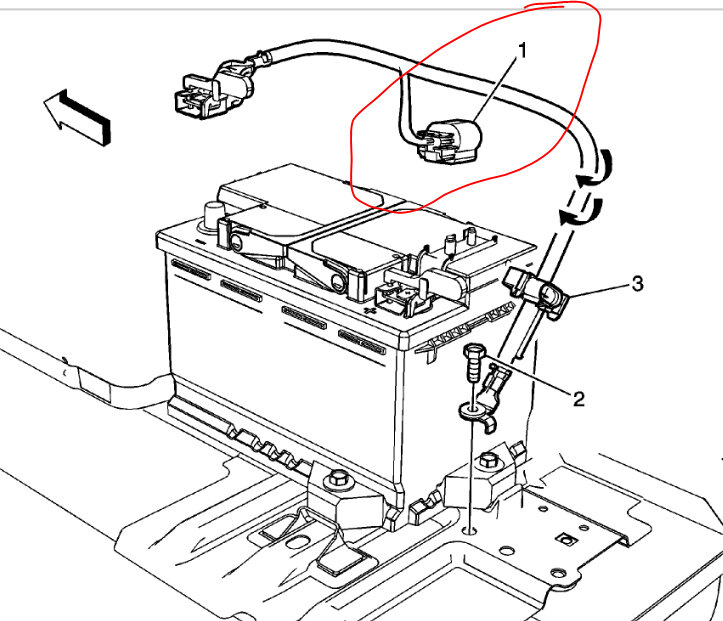

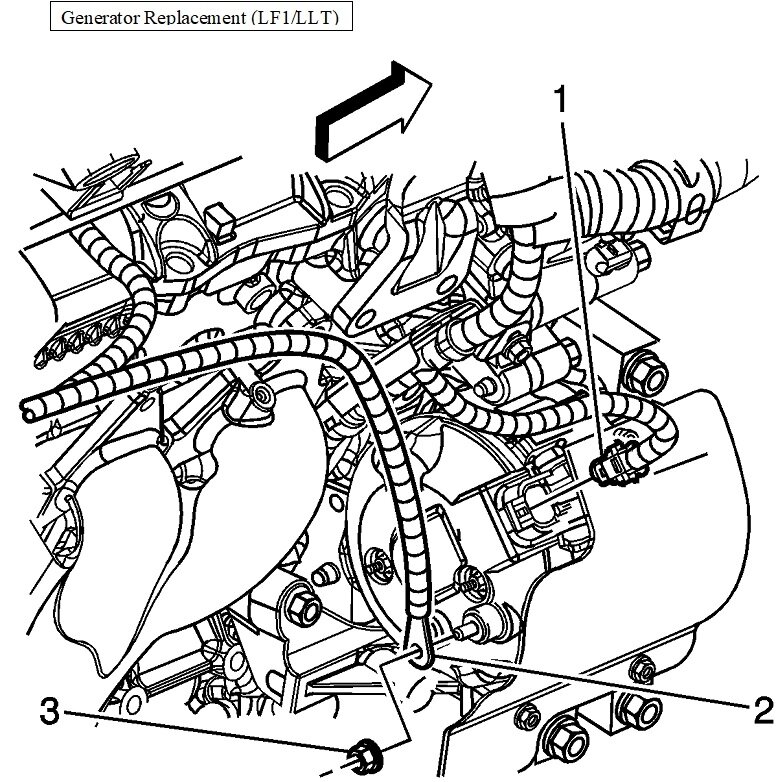

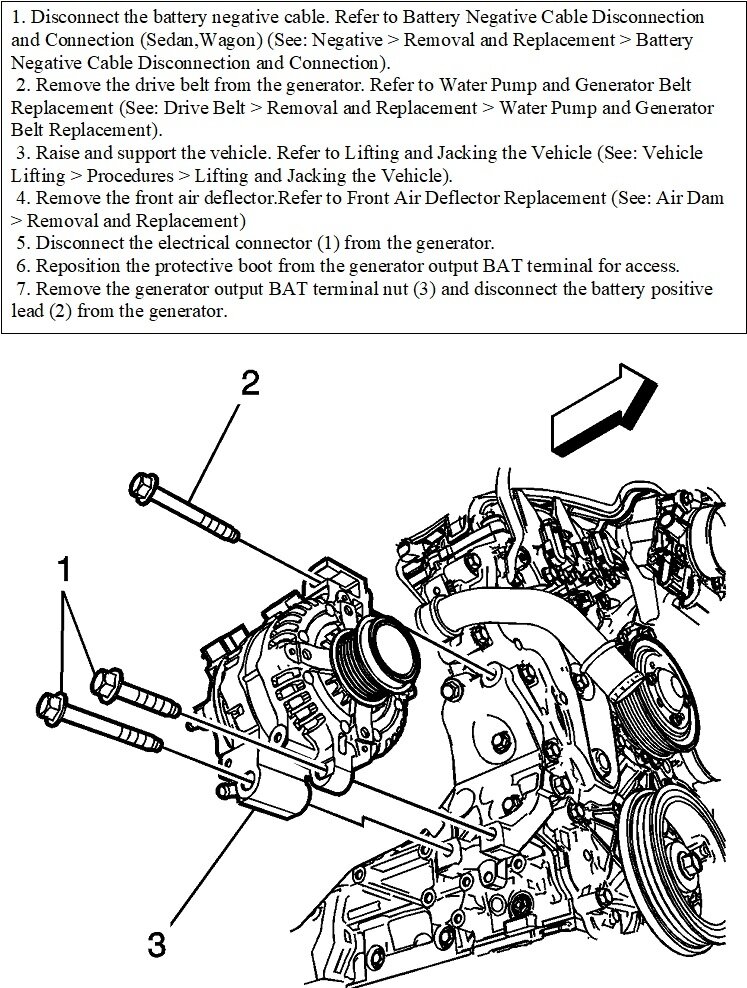

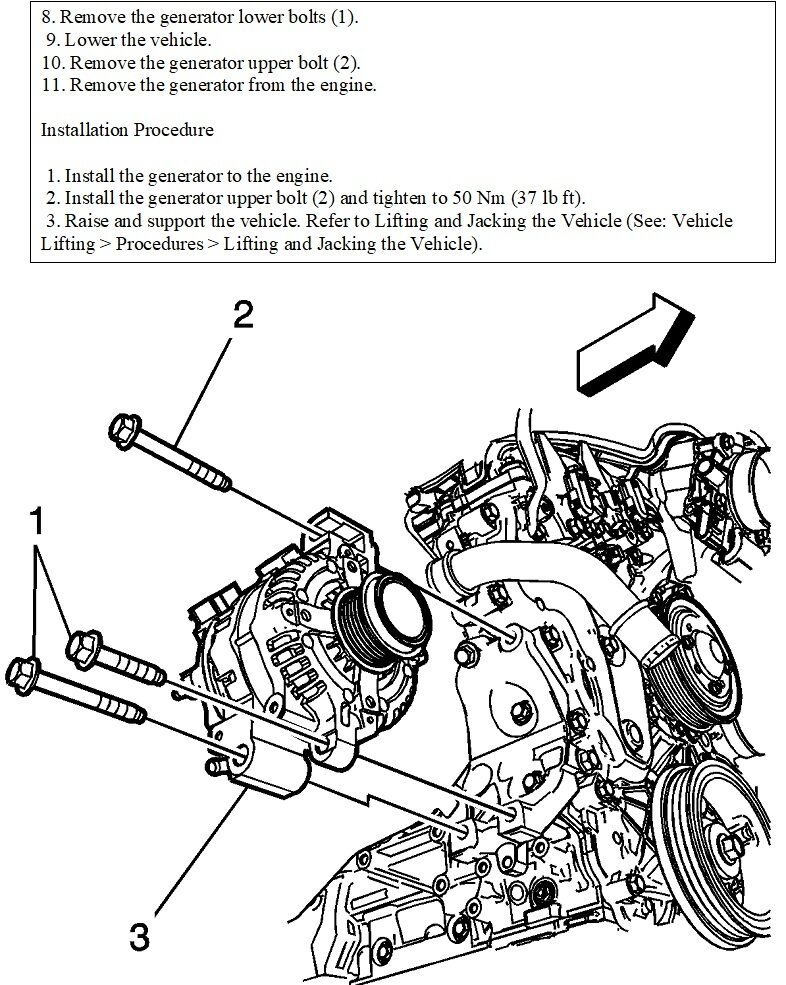

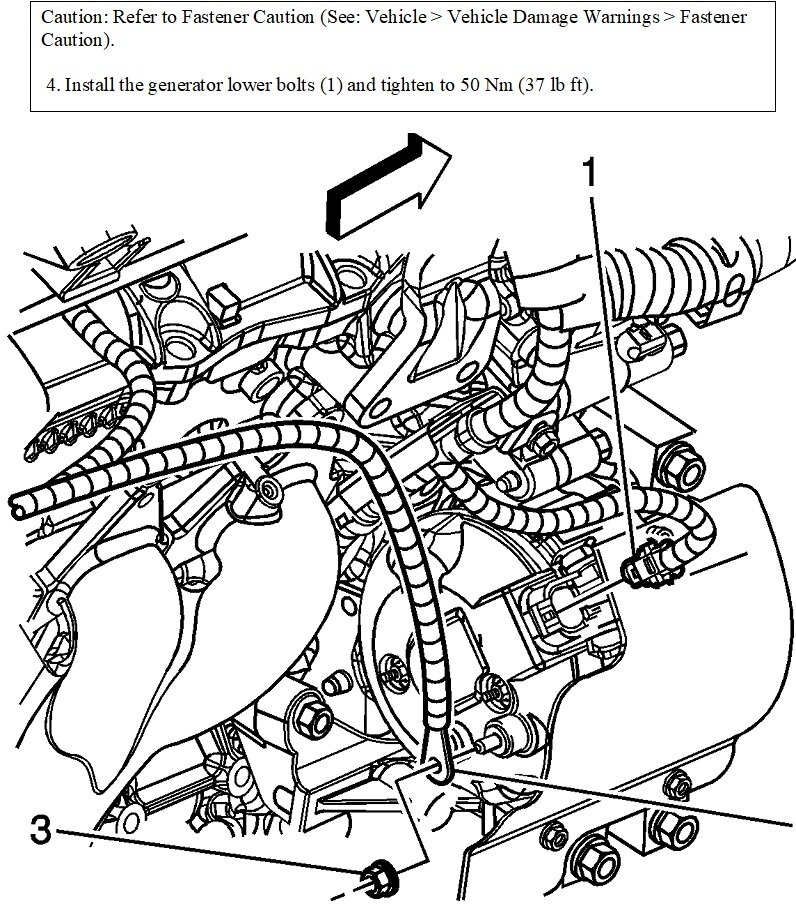

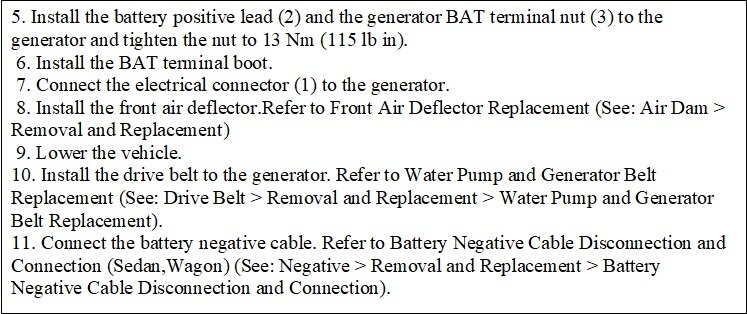

If testing shows the generator must be replaced, I copied the instructions for you from our online service manual. The steps are in these five drawings. Please let me know what you find.

Images (Click to make bigger)

Monday, November 28th, 2022 AT 9:29 PM