Hi and welcome back:

Here are the directions from alldata for install of the upper control arm:

UPPER

REMOVAL

NOTE: Raise the vehicle and support it with suitable safety stands.

Remove or disconnect the following:

1. Are and wheel assembly.

2. Air cleaner extension, if needed.

3. Brake hose.

- Nut and the screw.

- Bracket and the hose.

- Tie the hose out of the way.

4. Cotter pin.

5. Nut.

6. Upper control arm (101) from the knuckle (117).

7. Nuts.

8. Bolts.

9. Upper control arm (101).

10. Bushings.

INSTALLATION

CAUTION: Always use the correct fastener in the proper location. When you replace a fastener, use ONLY the exact part number for that application. The manufacturer will call out those fasteners that require a replacement after removal. The manufacturer will also call out the fasteners that require thread lockers or thread sealant. UNLESS OTHERWISE SPECIFIED, do not use supplemental coatings (paints, greases, or other corrosion Inhibitors) on threaded fasteners or fastener joint interfaces. Generally, such coatings adversely affect the fastener torque and joint clamping force, and may damage the fastener. When you install fasteners, use the correct tightening sequence and specifications. Following these instructions can help you avoid damage to parts and systems.

Install or connect the following:

1. Bushings.

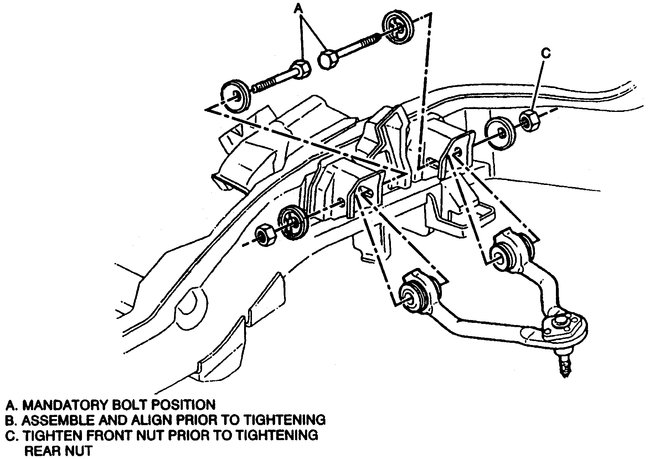

2. Upper control arm (101) to the frame (95).

3. Bolts and the washers.

- Be sure the bolt heads are opposed inside the bracket.

4. New nuts.

- Tighten the front nut prior to tightening the rear nut.

- Tighten nuts to 190 Nm (140 ft. Lbs.).

- The nuts must be tightened with the control arm at "Z" Height.

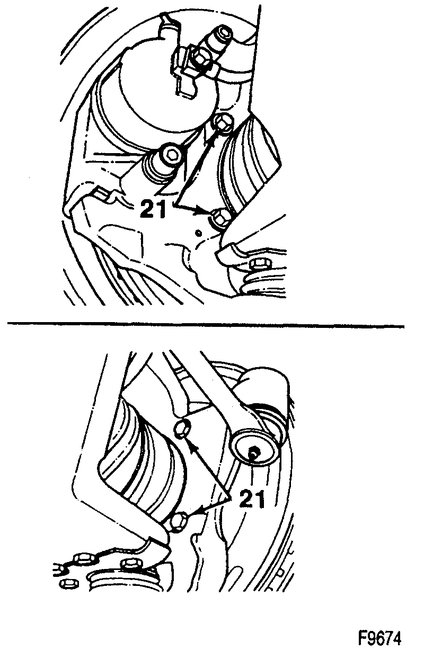

5. Upper ball joint (115) stud to the knuckle (117).

6. Nut to the upper ball joint (115) stud.

- Tighten nut (129) to 100 Nm (94 ft. Lbs.).

- Tighten the nut to align the cotter pin. Do not tighten more than 1/6 turn.

7. New cotter pin.

- Bend the cotter pin ends against the nut flats.

- Remove the support from the knuckle.

8. Brake hose.

- Bracket and the hose.

- Screw and the nut.

9. Air cleaner extension, if needed.

10. Tire and wheel assembly.

- Lower the vehicle.

____________________

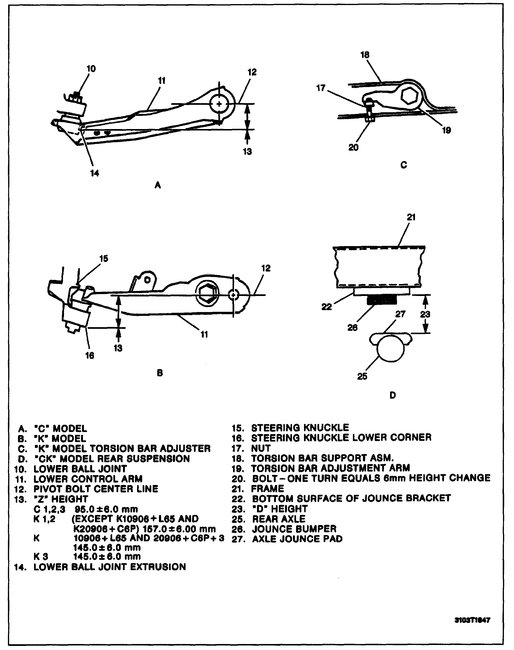

You will notice that it indicates the vehicle must be at Z height when tightening. That is when the vehicle is on a level surface (on the ground) and the correct trim height is confirmed. On your vehicle, height adjustment is done with the torsion bar, but you shouldn't have taken anything apart with that. So, it should be correct.

To determine Z height, you have to measure from the pivot bolt center line to the lower corner of the steering knuckle to obtain a measurement. The measurement should be right around 4.5".

Here are the directions for torsion bar adjustment if needed. See pic 3

1. Lift the front bumper of the vehicle up about 38 mm (1.5 inches).

2. Gently remove your hands and let the vehicle settle on its own.

3. Repeat the operation twice more for a total of three times.

4. Measure the "Z" dimension.

5. Push the front bumper of the vehicle down about 38 mm (1.5 inches).

6. Gently remove your hands and let the vehicle rise on its own.

7. Repeat the operation twice more for a total of three times.

8. Measure the "Z" dimension.

9. Find the average of the high and low measurements. This is the true "Z" dimension.

Again, you didn't adjust ride height, so this shouldn't be an issue.

Let me know if this helps or if you have other questions.

Joe

Images (Click to make bigger)

Sunday, December 30th, 2018 AT 2:59 PM