Servicing Tires and Wheels

BALANCING

The tire and wheel assemblies should be balanced using a dynamic balance either on the car or

off the car.

The dynamic type produces a more accurately balanced tire and wheel assembly than does the

static type and is therefore recommended.

Once you have properly mounted and inflated a tire, you must balance the assembly. Balancing

your performance customers’ tires and wheels is another area where attention to service can pay

off. These customers are driving vehicles with steering and suspension systems that are so

sensitive that even the average driver can feel minor handling problems. Poorly balanced tires are

what will drive them to other tire dealerships.

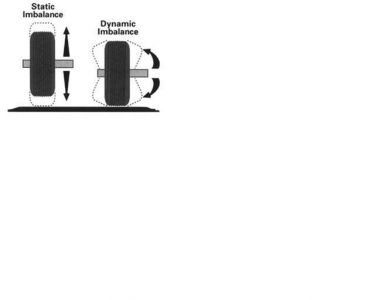

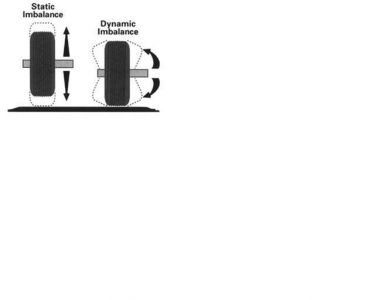

Proper balancing is critical for optimal vehicle performance, especially at highway speeds. When

tire and wheel assembly are unbalanced, a vibration can result from wheel shimmy (shaking from

side to side) or wheel tramp (tire and wheel hopping up and down). Therefore, it is important that

these assemblies are in both static and dynamic balance.

Static balance exists when the weight mass is evenly distributed around its axis of rotation. Static

imbalance can be detected from vibrations through the seat, floor and steering column. These

heavy or light spots in the tire should be eliminated by placing wheel weights, equally distributed,

on both the inside and outside rim flanges.

Dynamic balance exists when the weight is equally distributed both around its circumference and

on either side of its centerline. Dynamic imbalance is the result of heavy or light spots on the side

or off-center of the wheel, tire tread or sidewall.

Note: A tire can be in static balance and still have dynamic imbalance.

The best way to ensure proper balance is to use an off-the-car computer-balancing machine.

Follow the machine’s operating instructions step by step. The balance will measure the

assembly’s fluctuations in weight by stimulating its operating on a vehicle. The balance will

indicate that correct amount of weight to use and where to place each weight.

There are three types of weights � adhesive-backed lead weights, coated-lead clip weights and

uncoated lead clip weights. On steel wheels, any type of weight can be used. You should note,

however, that the uncoated lead clip-on weights scratch the steel, inviting rust.

Only adhesive-backed weights or coated-lead clip weights should be used on aluminum wheels as

uncoated lead clip-on weights can crack the clear coating on custom wheels, causing corrosion.

Remember that your high performance customer has invested heavily in his or her custom

wheels. Not only do you need to be careful not to scratch the wheels with weights, but you also

need to be aware of the customer’s preference for placement of the weights. Many high

performance customers do not want weights placed on the outside of the wheels.

Warning: Always make sure that weights used on the inside surface of a wheel do not

interfere with the brake calipers or other mechanical components.

Once the weights are placed on the wheel, place the assembly back on the balancer and verify that

it is correctly balanced.

Improving Handling Characteristics

In motorsports competition, adjustments to everything from tires to spoilers are commonly made

to give a vehicle specific handling qualities. One of the best ways to improve the handling of high

performance vehicles designed for competition is to modify tire and wheel variables.

Adjustments are commonly made to reduce oversteer and understeer. Oversteer is when the rear

of a vehicle loses grip before the front of the vehicle in a cornering situation. Understeer is the

opposite. It is when the front of a vehicle loses grip before the rear of the vehicle. To the drive,

understeer feels like the vehicle is resisting turning into a corner. The best cornering attitude is a

neutral steer where the tires are achieving optimum performance. Use the following chart when

making oversteer and understeer handling adjustments to performance vehicles. Remember that

when increasing or decreasing tire pressures, use 2 psi increments for best results.

Warning: Carrying any of the following adjustments to an extreme may magnify the

problem you are attempting to correct. For example, one way to reduce understeer is to add more

inflation pressure to the front tires. If you add too much pressure, you may create an even greater

understeer problem, as less tread will contact the road surface, providing less cornering ability.

Tire Rotation

To obtain even and maximum tire wear, it may be necessary to rotate your tires. (Please note: for

some tires like the Michelin� XH4� . X-One� radial and Uniroyal� NailGard, tire rotation is

required to maintain its warranty status.) Refer to your vehicle owner’s manual for instructions on

tire rotation.

Some tires have arrows on the sidewall showing the direction in which the tire should turn. When

rotating this type of tire, care must be taken to maintain the proper turning direction as indicated

by the arrows.

Unless otherwise recommended by the vehicle manufacturer’s owner’s manual, tires should be

inspected every 6,000-8,000 miles and rotated at the first sign of uneven or irregular wear. Any of

the rotation patterns shown can be used:

Following the tire rotation guidelines in the vehicle owner’s manual, and/or using the suggested

rotation patterns, will help to distribute wear equally among tires. Here are some other important

points to remember when rotating tires:

1. Be sure to adjust tire inflation pressures. Refer to the vehicle manufacturer’s tire placard

for recommended pressures. Make a special effort to verify the correct inflation pressure

for new wheel positions.

2. Never include a “Temporary use Only” spare tire in any of the previous rotation patterns.

If the vehicle’s owner has a spare that is a regular size tire and wants to include it in the

rotation pattern, follow this procedure:

Use one of the rotation patterns shown. Insert the spare in the right rear position and

place the tire that would have been rotated to the right rear position in the trunk as a new

spare.

3. Under normal driving conditions, the difference in wear rate can be substantial between

front and rear tires on front wheel drive vehicles. Always refer to the vehicle owner’s

manual for rotation recommendations.

4. Check the vehicle’s mechanical condition. Sagging suspensions, worn brakes, front-end

alignment, etc. can affect tire wear. Refer to the vehicle owner’s manual or recommended

maintenance.

Remember, unless otherwise recommended by the vehicle owner’s manual, tires should be

inspected every 6,000-8,000 miles and rotated at the first sign of uneven or irregular wear.

Any rotation pattern or procedure may be followed; including those indicted by the vehicle

manufacturer’s owner’s manual. Whenever only two tires are replaced, the new tires should be

put on the rear axle.

Telling your customers about recommended rotation intervals is another way to maintain

customer satisfaction. After customers purchase tires, you may want to follow up with them by

sending a postcard that reminds them of the rotation “rules of thumb.”

Tire Storage

All tires should be stored in a cool dry place indoors so there is no danger of water collecting

inside them. Serious problems occur with tube type tires when they are mounted with water

trapped between the tire and the tube.

Due to pressurization, the liquid can pass through the innerliner and into the casing plies. (This

can result in sudden tire failure.) Most of the problems of this nature, encountered with tube type

tires, have been due to improper storage, which permitted water to enter the casing between the

tire and tube prior to mounting.

Tires should be stored in a cool place away from direct sunlight, sources of heat and ozone such

as hot pipes and electric generators. Exposure to these elements during prolonged periods of time

will exhaust the tire’s oxidation and weathering agents within the rubber compounds and result in

cracking. Be sure that surfaces, on which tires are stored, are clean and free from grease, gasoline

or other substances, which could deteriorate the rubber. (Tires exposed to these materials during

storage or driving could be subject to sudden failure.)

Tire Repair

External, or outside in, repair methods using sealant, string, rubber bands or rivet type plugs are

not recommended. The tire must be demounted for inspection of possible internal damage. Refer

to the appropriate tire repair manual if available or follow the recommended RMA procedures.

Chains

Although MAST branded snow tires have proven to be quite capable on winter roads, sever

winter conditions sometimes necessitate the use of chains. Certain procedures must be followed

when utilizing chains inorder to optimize performance and minimize tire wear/damage.

1. Chains should be utilized only when necessary. The probability of damage to the tire

and/or the chains increase as the driving speed and distance traveled increase. Use on dry

pavement is especially conducive to wear since the lubricating feature of the water

(snow) is not present.

2. Chain manufacturers give size recommendations for radial ply tires, which must be

adhered to for optimum utility and performance. Size recommendations are usually given

for the highway tread design tire. If the chain is to be used on a snow tire, it may be

necessary to use the next large chain size to allow for the necessary amount of chain

movement relative to the tire. Check for proper clearances between chains and vehicle.

Consult the individual chain manufacturer for specific recommendation because sizing

and fitment may vary with the chain type.

3. Normally, the proper fit for any type of chain is achieved by hand tightening it and

locking it in place. After one or two miles of driving, the chain should be retightened by

hand. This will take up any slack, which may have formed due to the unraveling of

components tangled in storage.

Warning: Improper chain type or size may damage the sidewall of a tire, causing failure.

Monday, November 5th, 2007 AT 7:46 PM