Dandy. In my experience, the red "Brake" warning light turns on for a problem in the base brake system. That can be due to the parking brake is not fully released, the brake fluid level is low in the reservoir, or the pressure-differential switch is tripped in the combination valve. That valve trips when equal pressures can't build up in both halves of the system due to a leak. This applies to every car and light truck.

The yellow "ABS" light turns on when a problem is detected in the ABS system. The computer sees when the red warning light is on, but it doesn't know why it's on. It only knows the cause could affect its ability to perform its job properly. That causes it to turn itself off, and turn on the yellow light. Therefore, a problem in the base brake system turns on the red light, and that makes the ABS Computer turn on the yellow light. A problem in the ABS system turns on the yellow light, but there is no problem in the base brake system, so the red light doesn't turn on.

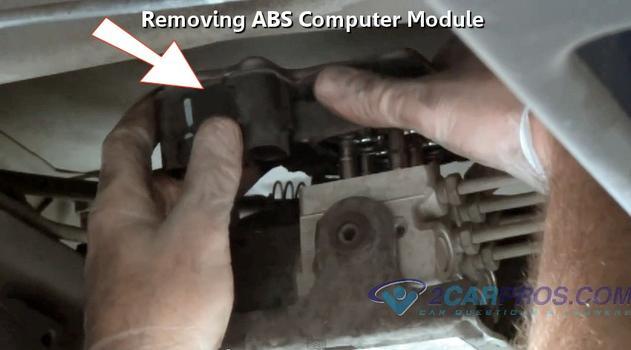

The photos you included, (thank you), show the valves that control the flow of brake fluid during a skid. There is no brake fluid on that side, but still, do not use any type of oil there. That oil can reach the side of the rubber lip seals opposite of where the brake fluid is. The problem isn't the oil getting into the brake fluid. The problem is the rubber is not compatible with petroleum-based products. Brake fluid is a glycol product. The rubber will become soft and mushy, and will grow bigger. That will impede the movement of the valves at first, and eventually the seals will start to leak.

Those valves move first to block fluid flow to a wheel that is slowing down more than the others when the brakes are applied. If the wheel speed doesn't pick back up, another valve opens to bleed fluid pressure off. Once the wheel speeds up again, another valve opens to allow more brake fluid to flow to that brake. This "block, bleed, apply" can occur up to 30 times per second, although most systems do that just as effectively at 15 times per second. That is the buzzing you hear and feel when the ABS engages.

Recently I learned there are indeed some systems that do turn the red light on too when there is a problem in the ABS system and the yellow light is on. On some, the yellow light can flash too for certain conditions. Keep that in mind when both lights are on, but in general, diagnose the red light first since solving that one is likely to solve the yellow one.

That pulsing of the valves 15 times per second is more effective with disc brake calipers because the pads are always right next to the rotors. Little piston movement is needed to apply the brake. Some systems use rear drum brakes. Those shoes have to move a lot before they contact the drum. The need for that is designed into the ABS system. If a parking brake cable is rusted in the partially-applied position, the brake shoes can be held not fully retracted, and they have to move very little to contact the drum. That brake can be reapplied too easily during an ABS stop, reducing its effectiveness.

If there's a leak in half of the hydraulic system, you may never know that on some GM vehicles. A valve in the master cylinder can trip to block fluid from flowing to the leak. I don't know if that valve is used with vehicles that have ABS, but regardless, if there is an inability to build fluid pressure in half of the system, the pressure-differential switch will turn on the red warning light. The ABS system needs to be able to raise and lower the pressure in both halves of the system. Since it can't do that with no pressure in one part, the ABS system turns off, and the yellow light turns on. This is another case where the only problem is in the base brake system, but the ABS is unable to do its job, so the yellow light is also on.

If you're worried about one of the valves in your hydraulic controller, all of my training classes have included a discussion of the self-tests the computer performs at start-up. That takes place while the yellow light is on for the first six seconds when the ignition switch is turned on. All of the electrical circuits are checked for continuity and shorts. Those problems will be detected right away, a fault code will be set, and the yellow light will stay on.

Mechanical things are tested when the vehicle begins moving. The computer wants to see wheel speed signals and an input from the brake light switch. Somewhere along this self-test procedure, the computer pulses the valves in the controller on and off, then it watches for the signals from responding pressure switches. This is where a malfunctioning valve would be detected. If no problem has been detected and no fault code related to that has been set, there is nothing you have to do or fix in that assembly. Sticking valves are unheard of because they are exercised each time you drive the vehicle. Even brake fluid contamination won't be a suspect for an ABS problem because that will cause other symptoms first. By far the first symptom is most often a high and hard brake pedal caused by the lip seals in the master cylinder growing past the fluid return ports. That traps the fluid, then as it heats up and expands, it applies the brakes harder and harder, until eventually, one or two brakes are smoking, or the car won't move. Proper ABS operation isn't a concern if the car won't move.

Monday, April 3rd, 2017 AT 5:13 PM