I have done some fairly extensive basic troubleshooting and testing. Please read all I have considered and tests I have performed before jumping to diagnostic conclusions. I have a degree in electronics, so I do know how to correctly use a voltage and continuity tester to check circuits.

All of the brake lights in the rear taillights function correctly. The cab lights in the 3rd brake light function correctly. All 4 bulbs in the 3rd brake light are good (I checked them with a continuity tester and an independent 12v power source.) There is no corrosion or discoloration on any of the terminals for all 4 bulbs and also the main harness connector going into the cab of the truck behind the lamp assembly.

Using a continuity tester, I have successfully verified:

1. Continuity across the lamp and socket connectors.

2. Continuity across the wiring harness connectors.

3. Continuity from harness connector to chassis ground.

4. Continuity across all fuses in the fuse block under the hood.

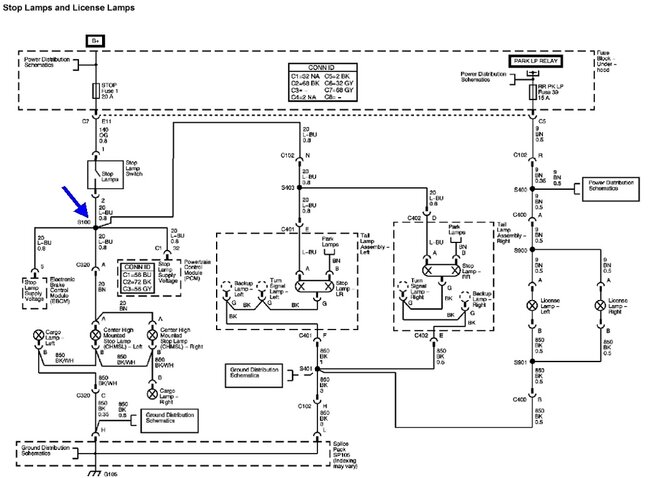

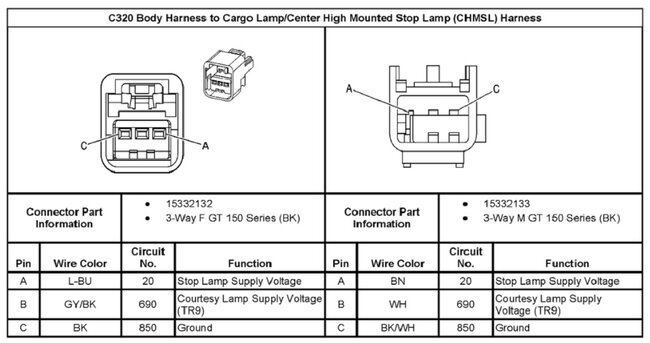

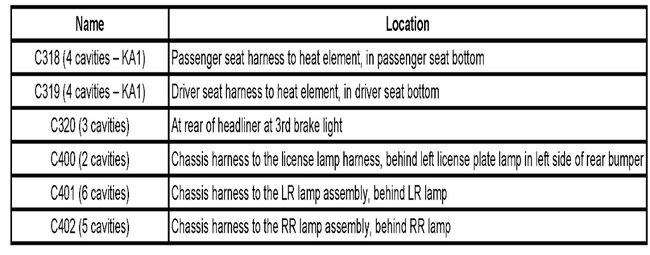

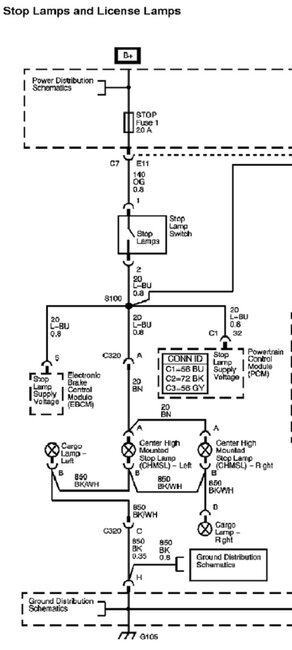

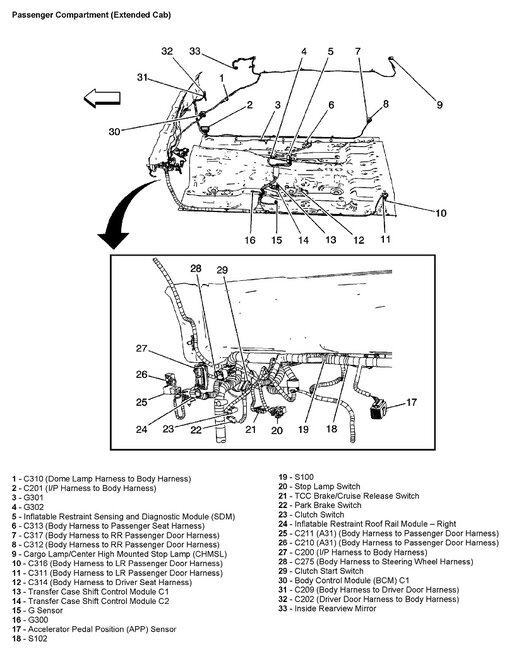

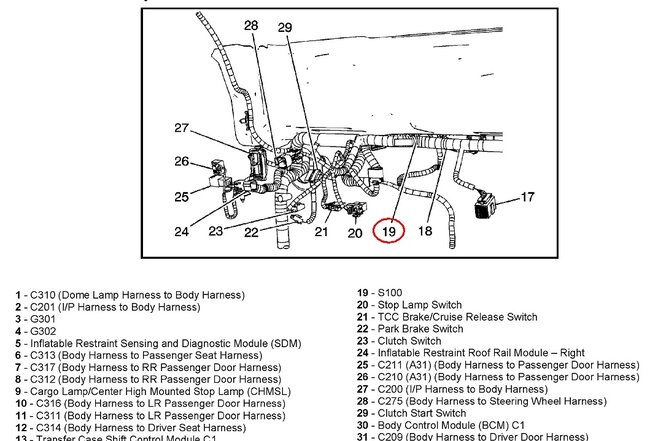

There is 0 voltage in the light blue wire at the main connector from the cab to the 3rd taillight harness when pressing down on the brake pedal. I have tested every fuse in the fuse block under the hood.

If I unplug the main connector from the cab to the third brake light assembly and connect 12v to the black/white wire and connect the brown wire to chassis ground, the brake lights will light. I have not tried connecting 12v with the harness connected from the cab to the light bar to make sure I don't cause any damage to the wiring circuit(s) or fuse(s).

The factory rubber 3rd brake light gasket is in good condition and there is no evidence any moisture or dirt has ever been inside the lamp housing. So, at this point, I feel like the lamp assembly and bulbs are in good working order.

Where should I look/test to find the missing/damaged connection causing 0 volts to the light blue wire coming out of the cab when the brake pedal is pressed?

Thursday, February 1st, 2024 AT 5:42 PM