Dim/dull headlight or headlights can be dangerous as it inhibits the vision of the driver from seeing obstacles in the roadway. Fortunately there are only a handful of problems that can cause this issue (most of them simple) which we will go over in this guide.

What goes wrong?

As headlight systems evolve and become more active to road conditions brighter and more precise systems demand additional electrical current and computer controls. Corrosion and component wear can cause the headlight beam to be dull or almost non existent, this is not to be confused with a headlight lens that is foggy or if the lens material has degraded.

How much does it cost?

Since headlight systems utilize the vehicles BCM, (body control module), TIPM (totally integrated power module) IPDM (intelligent power distribution module) or LCM (lighting control module) depending on the manufacturer. Problems can range from a simple fuse that is blown, high resistance at an electrical connector, bad ground or replacement of the aforementioned control module the prices and effort can range greatly.

Lets get started!

Problems are listed according to difficulty, Step 1 being the simplest.

When a fuse goes out due to age or a sudden voltage surge when the system is

switched on its best to

check the system fuse

using a test light. This is done with the key in the on position while the headlight

system is energized (on). Locate the headlight system fuse using the cars owners

manual, fuse panel cover or by asking one of our technicians.

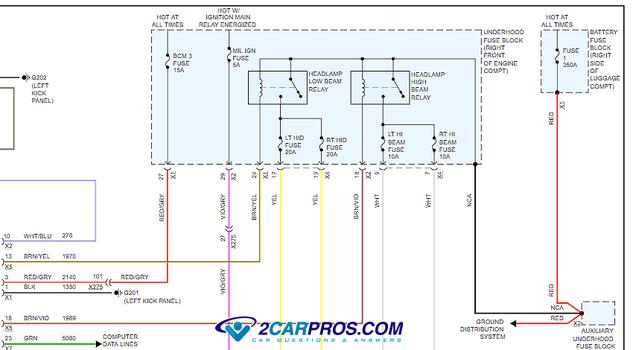

Additionally, there can be several fuses that control the system, to confirm the

fuse or fuses in question a wiring diagram can be used to identify said fuses such

as in the diagram below. Test and replace any fuse that fails the test (blown or

bad connection).

All headlight systems utilize wiring connectors that attach to the headlight

bulb or lens bulkhead connector which is made of plastic, within this plastic there

are metal electrical terminals that reside inside the connector. Because of the

amperage pulled through the circuit these connections can heat up causing resistance

and eventually and bad connection, this will happen to the power side of the circuit.

To check for this problem simply remove the connector to inspect for signs of burnt/melted

plastic and discolored (dark) terminals, this is easy to see and is common. To quickly

fix the problem use an Exacto or other sharp object to clean the electrical contacts

on both the headlight bulb and connector. This will work temporally, the correct

repair is to replace both the headlight bulb and connector.

Watch the Video!

Please watch this video of the job being done, then continue down the guide to glean additional helpful information.

Headlight systems depend on a proper ground to complete their circuit, if the ground is dirty or loose it will cause a dim or dull headlight condition. Many times you can locate this ground by easily following the wiring harness and observing the "break out" wire that is attached to the car sub-member or radiator core support. Confirm the connection by removing the small bolt or screw while cleaning the connection and reinstall, that's all there is to it.

The headlight switch controls and current flow on older cars while in newer cars it simply signals a control module. Older cars, remove the headlight switch to inspect the electrical connector for burned terminals much like you would the headlight bulb. If burn marks or discoloration is present replace the switch and the connector. Again cleaning the connection will help for a short time. Headlight switches on newer cars rarely go out.

Control modules do fail on newer cars causing a dim or dull headlight operation, to confirm this issue a CAN Scan (controller area network) needs to be performed.

Questions?

Our certified technicians are ready to answer dim headlight questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.