Hi,

I read your post and have an idea as to what may be happening. The first thing is the original fuel smell followed by the sulfur odor.

The smell of rotten eggs can be due to a compound called hydrogen sulfide. It can be in the fuel. However, other things can cause it as well. An internally damaged catalytic converter, an engine that is running too hot, or a fuel pressure regulator which has failed allowing too much fuel to enter the combustion chamber.

Since you smelled fuel, I would start with checking fuel pressure. If the regulator is bad allowing pressure to rise above the manufacturer's specs, it will cause the fuel mixture to be too rich. As a result, you can get this type of smell. We have two ways that can be checked.

First, if you have a live data scanner, examine the short term fuel trims. They should be around 0. If they are in the higher negative numbers, that indicates the computer is trying to lean the mixture and could be an indicator of high fuel pressure.

Second, check fuel pressure and regulator. Here is a link that shows how to test fuel pressure in general:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

_______________________________________________

Here are the directions specific to your vehicle for testing. The attached pics correlate with the directions. Additionally, pressure specifications are included in the directions.

______________________________________________

2013 Mazda Truck CX-9 AWD V6-3.7L

Fuel Line Pressure Inspection

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Pump Fuel Pressure Testing and Inspection Component Tests and General Diagnostics Fuel Line Pressure Inspection

FUEL LINE PRESSURE INSPECTION

FUEL LINE PRESSURE INSPECTION [MZI-3.7]

WARNING:

- Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death. Fuel can also irritate skin and eyes. To prevent this, always complete the "BEFORE REPAIR PROCEDURE".

1. Complete the "BEFORE SERVICE PRECAUTION". See: Fuel Pressure > Component Tests and General Diagnostics > Before Service Precaution

2. Disconnect the negative battery cable. See: Battery > Removal and Replacement > Battery Removal/Installation

3. Remove the engine cover. See: Engine > Removal and Replacement > Engine Cover Removal/Installation

4. Perform the work using the following procedure.

- Set the air cleaner cover aside.

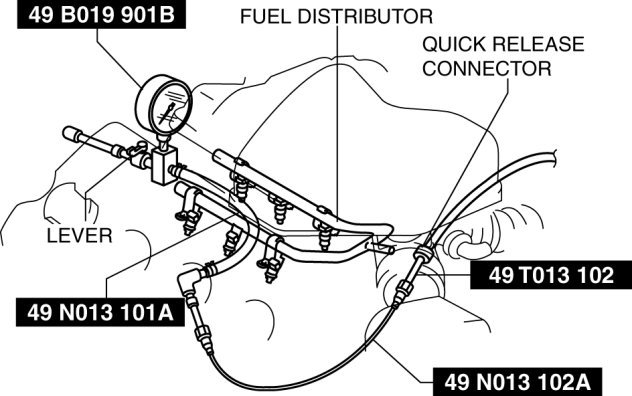

- Disconnect the quick release connector from the fuel distributor. See: Fuel Line Coupler > Removal and Replacement > Quick Release Connector Removal/Installation

- Connect the thin part of SST (49 T013 102) to SST (49 N013 102A) until a click sound is heard.

pic 1

- Connect the thick end of SST (49 T013 102) to the quick release connector until a click sound is heard.

- Connect SST (49 B019 901B) to SST (49 N013 101A).

- Connect SST (49 N013 101A) to SST (49 N013 102A) until a click sound is heard.

- Turn the SST lever so that it is 90° to the hose as shown in the figure.

5. Verify that the selector is in N or P position.

6. Start the fuel pump using the following procedure.

Using M-MDS

- Connect the negative battery cable. See: Battery > Removal and Replacement > Battery Removal/Installation

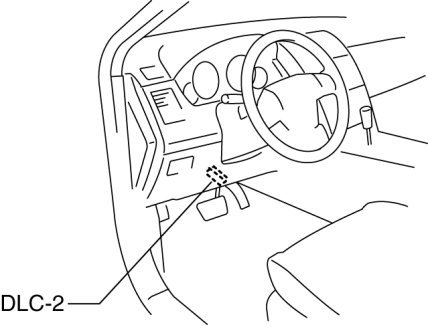

- Connect the M-MDS to the DLC-2.

pic 2

- Using the simulation function "FP", start the fuel pump. See: Computers and Control Systems > Reading and Clearing Diagnostic Trouble Codes > On-Board Diagnostic Test

Without using M-MDS

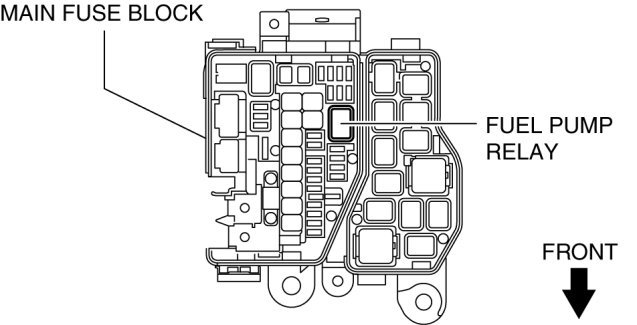

- Remove the fuel pump relay.

pic 3

CAUTION:

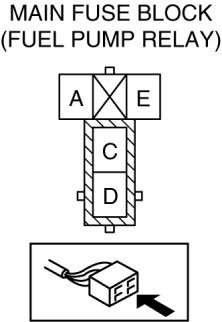

- Short the specified terminals because shorting the wrong terminal of the main fuse block may cause malfunctions.

- Using a jumper wire, short fuel pump relay terminals C and D in the main fuse block.

pic 4

- Connect the negative battery cable and operate the fuel pump. See: Battery > Removal and Replacement > Battery Removal/Installation

7. Measure the fuel line pressure. (during key on engine off (KOEO))

- If not as specified, inspect the following:

Zero or low

- FP circuit

- FP

- Fuel line (clogging)

- Fuel leakage inside pressure regulator

High

- Pressure regulator

Fuel line pressure

- 375-450 kPa [3.83-4.58 kgf/cm2, 54.4-65.2 psi]

8. Stop the fuel pump using the following procedure.

Using M-MDS

- Stop the fuel pump using the "FP" simulation function. See: Computers and Control Systems > Reading and Clearing Diagnostic Trouble Codes > On-Board Diagnostic Test

Without using M-MDS

- Switch the ignition to off.

- Disconnect the negative battery cable to stop the fuel pump. See: Battery > Removal and Replacement > Battery Removal/Installation

9. Complete the "BEFORE SERVICE PRECAUTION". See: Fuel Pressure > Component Tests and General Diagnostics > Before Service Precaution

10. Disconnect the fuel pressure gauge and connect the fuel pipe.

11. Complete the "AFTER SERVICE PRECAUTION". See: Fuel Pressure > Component Tests and General Diagnostics > After Service Precaution

_________________________________

Because you started with a fuel smell that led to this rotten egg smell, this is where I would recommend starting. Do this and let me know what you find.

Take care and let me know if you have other questions.

Joe

Images (Click to make bigger)

Friday, April 10th, 2020 AT 8:38 PM