A/T: 03A / U151E

158K Miles

I bought this car second hand and along with it all its headaches too. One such headache are the transmission codes that seem to appear out of nowhere and cause drivability issues, (Limp Mode).

Symptoms I noted pre-check engine light: Delayed shifting from 1st to 2nd. Hard shifting after it decided to shift from those same gears. Everything driving wise seems as though the car could pull its own weight when it decided to shift... Meaning the grab factor after shifting seemed fine. Also didn’t notice any slipping or failure to want to move when accelerating. It was like that for appx. 2-weeks & progressively got worse until the dash CEL illuminated. Now it’s in limp mode it has no power. Scanned with a basic OBD II reader it gave me the following:

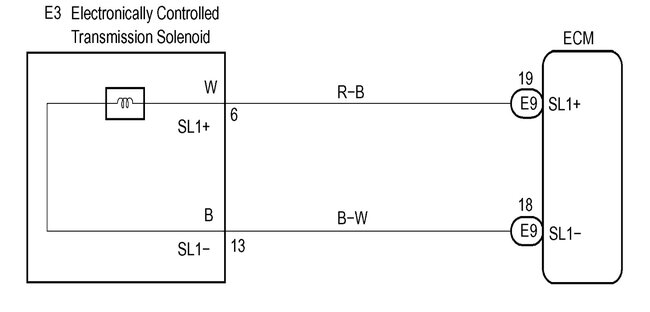

P0748 - Pressure Control Solenoid "A" electrical

P0986 – Shift solenoid “E” control circuit high, (This is a new code just randomly appeared)

TROUBLE SHOOTING:

- Found every ground in and around the engine bay cleaned them: No Difference

- Checked fuses in the engine bay fuse box and the cabin fuse box: No Difference

- Ensure battery was and is fully charged

- Replaced the trans. Fluid as it pertains to what was in the trans-pan only with (Toyota: A/T Fld type, T-IV)

- No big metal flakes noted or any other big objects in the Trans pan

- Replaced the Tans. Filter.

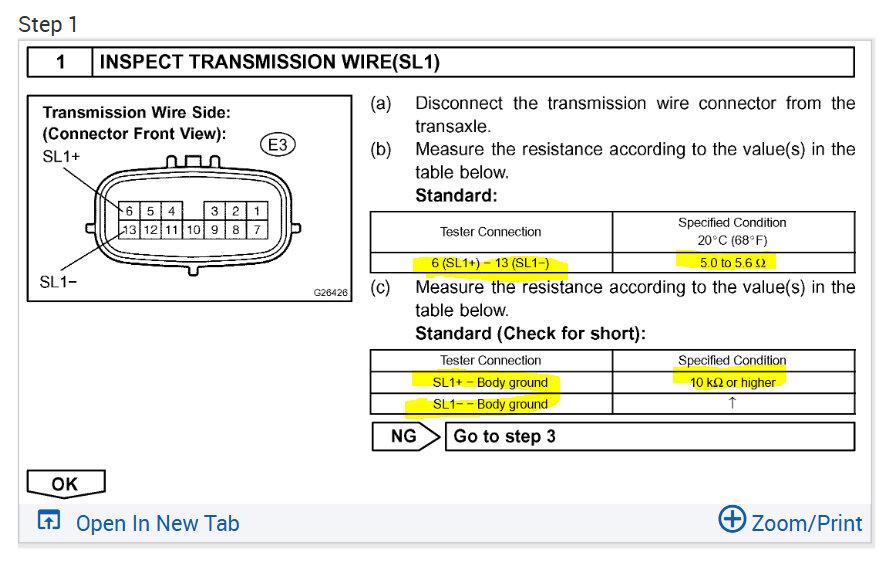

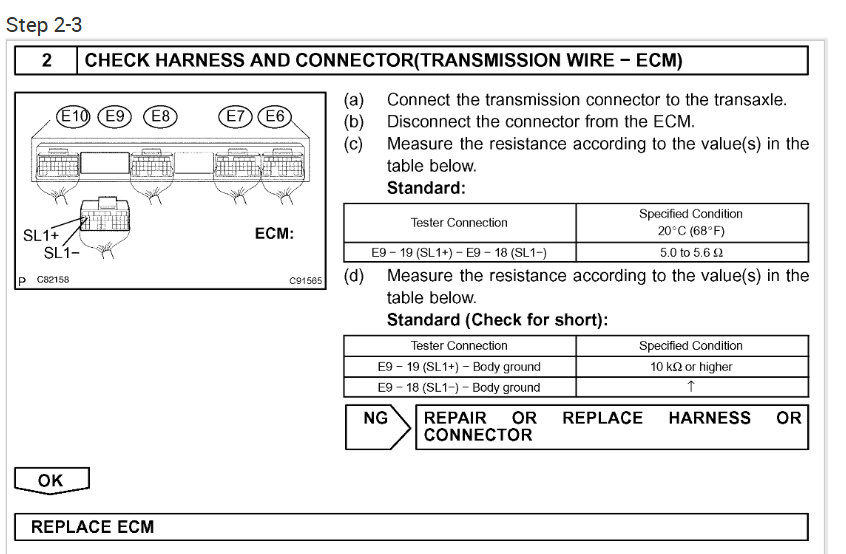

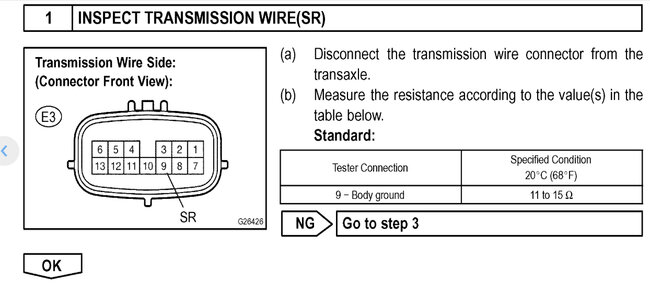

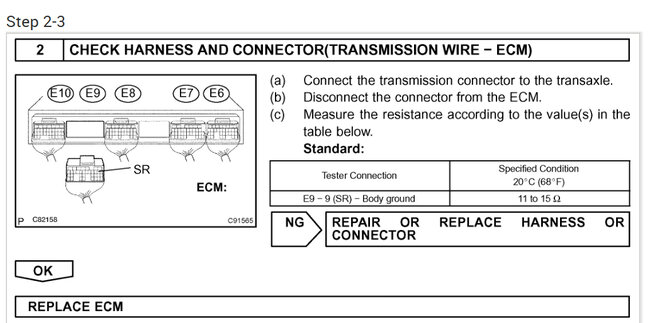

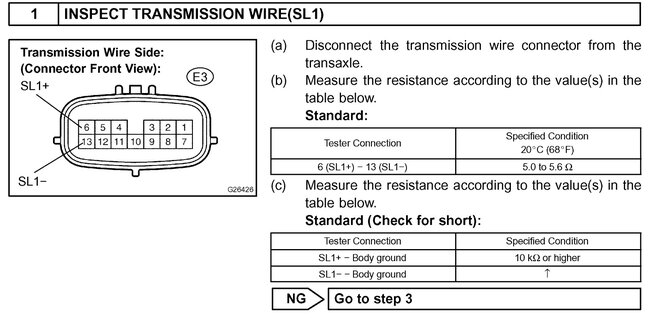

- Ck’d wire resistance from ECU plug to plug connection outside of the trans: 6.4 Ohms

- Ck’d damaged/corroded terminals at plug connection point on trans: No Defects

- Ck’d wiring resistance from the tranny plug to the valve body solenoid: 5.4 Ohms

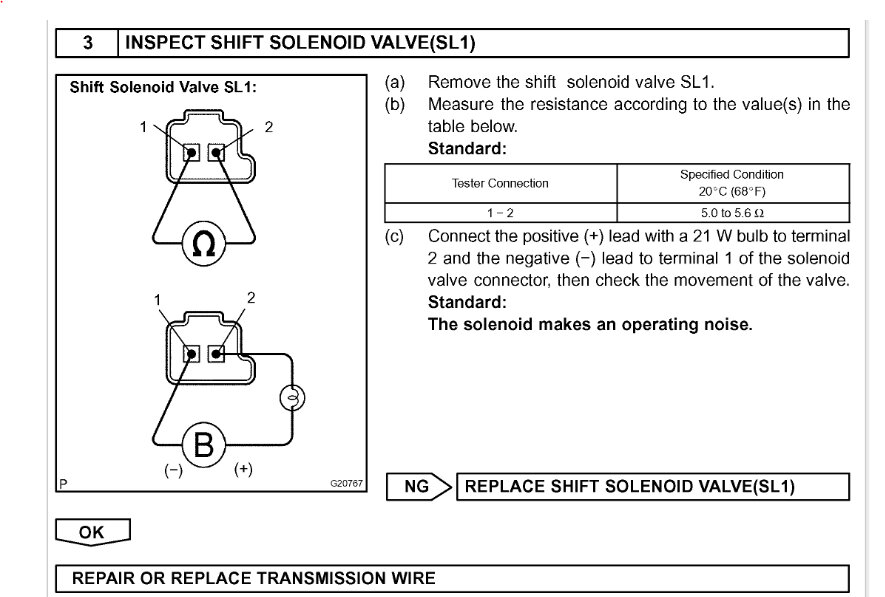

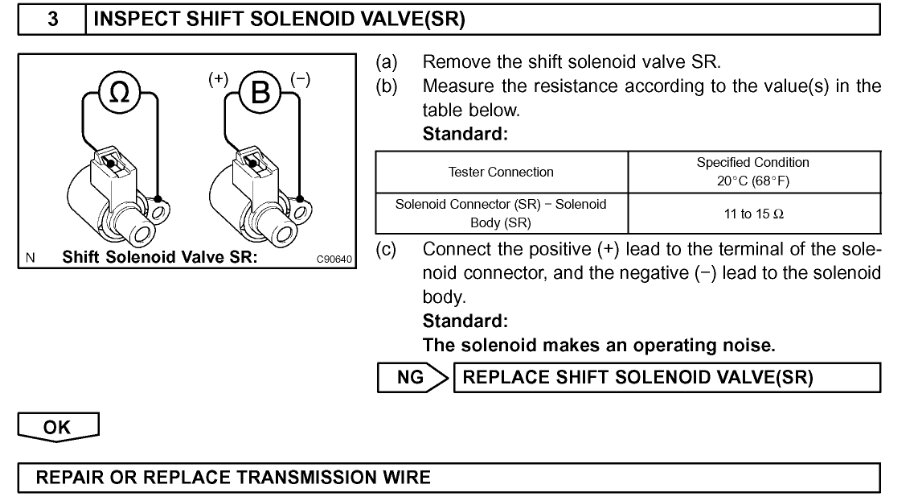

- Removed the SL1 Solenoid, inspected for damage: None Noted

- Applied 12V power: Solenoid, clicked/actuated fine

- Ck’d resistance at the solenoid terminals: 5.4 Ohms

- Ck’d solenoid terminals against it's casing (ground): No Defects - (OL)

- Reassembled trans. & Performed initial fluid service: On flat/level surface

- Warmed car to operating temp, rechecked & serviced as required: At proper Fld level

- Cycled through the gears 5 times, rechecking fluid level: Fluid at proper level.

- Cleared the DTC's: CEL went out & immediately returned with the same code: P0748

- Replaced the valve body wire harness: Did not Fix

- Replaced ECU with a rebuilt ECU:

-- DTC went out, Came out of Limp Mode

-- Fixed for roughly an hour. Shut car off after testing then restarted it 2-hour later and the DTC P0748 magically reappears.

- Removed the connector from the throttle body cleaned/inspected and reinstalled. For that my efforts received a new DTC: P0986 – Can’t seemingly clear this DTC either.

Oher then replacing the ECU again... Not sure what else to do?

Monday, March 17th, 2025 AT 2:02 PM