Hi,

Replacing the rear brakes and rotors isn't too hard of a job. When you do it yourself, make sure to purchase a lifetime brake pad. That way, you won't have to pay for them again in the future.

You can expect rear brake pads to last approximately 30,000 miles. However, that can change based on driving habits and terrain.

First, here is a link that shows how in general they are replaced. You can use this as a guide:

https://www.2carpros.com/articles/how-to-replace-rear-brake-pads-and-rotors

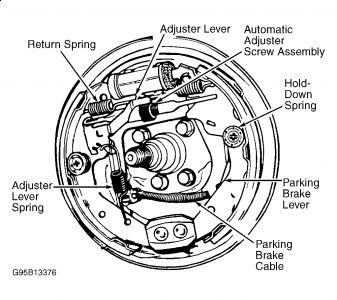

Here are the directions specific to your vehicle. The pics below correlate with the directions.

______________________

2005 Dodge Neon L4-2.0L VIN C

Rear

Vehicle Brakes and Traction Control Disc Brake System Brake Pad Service and Repair Procedures Removal and Installation Rear

REAR

BRAKE PADS/SHOES - REAR DISC

REMOVAL

NOTE: Before proceeding, Refer to WARNING.

1. Raise the vehicle.

2. Remove both rear tire and wheel assemblies from vehicle.

NOTE: Perform Step 3 through Step 7 on each side of vehicle to complete shoe set removal. In some cases, it may be necessary to retract the caliper piston in its bore a small amount in order to provide sufficient clearance between the shoes and the rotor to easily remove the caliper from the knuckle. This can usually be accomplished before the guide pin bolts are removed, by grasping the rear of the caliper and pulling outward working with the guide pins, thus retracting the piston. Never push on the piston directly as it may get damaged.

pic 1

3. Remove the two caliper guide pin bolts (Fig. 28).

pic 2

4. Remove the caliper assembly from the brake adapter by first rotating the top of the caliper away from the rotor, and then lifting the caliper assembly off the machined abutment on the adapter (Fig. 29).

pic 3

5. Hang the brake caliper from rear strut using wire or cord to prevent the weight of the caliper from damaging the brake hose (Fig. 30).

pic 4

6. Remove the outboard brake shoe from the caliper by prying the brake shoe retaining clip over the raised area on the caliper. Then slide the brake shoe down and off of the brake caliper (Fig. 31).

pic 5

7. Pull the inboard brake shoe away from caliper piston until the retaining clip is free from the cavity in the piston (Fig. 32).

CLEANING

Warning: dust and dirt accumulating on brake parts during normal use may contain asbestos fibers from production or aftermarket brake linings. Breathing excessive concentrations of asbestos fibers can cause serious bodily harm. Exercise care when servicing brake parts. Do not sand or grind brake lining unless equipment used is designed to contain the dust residue. Do not clean brake parts with compressed air or by dry brushing. Cleaning should be done by dampening the brake components with a fine mist of water, then wiping the brake components clean with a dampened cloth. Dispose of cloth and all residue containing asbestos fibers in an impermeable container with the appropriate label. Follow practices prescribed by the occupational safety and health administration (osha) and the environmental protection agency (epa) for the handling, processing, and disposing of dust or debris that may contain asbestos fibers.

INSPECTION

Visually inspect brake shoes (pads) for uneven lining wear. Also inspect for excessive lining deterioration. Check the clearance between the tips of the wear indicators on the shoes (if equipped) and the brake rotors.

If a visual inspection does not adequately determine the condition of the lining, a physical check will be necessary. To check the amount of lining wear, remove the disc brake shoes from the calipers.

Measure each brake shoe. The combined brake shoe and its lining material thickness should be measured at its thinnest point.

For rear disc brake shoes, when a set of brake shoes are worn to a thickness of approximately 7.0 mm (9/32 inch), they should be replaced.

Replace both disc brake shoes (inboard and outboard) on each caliper. It is necessary to replace the shoes on the opposite side of the vehicle as well as the shoes failing inspection.

If the brake shoe assemblies do not require replacement, be sure to reinstall the brake shoes in the original position they were removed from.

INSTALLATION

CAUTION: When installing new brake components, be sure to use correct parts. Parts designed for BR3 Performance Brake System must not be mixed with other brake systems. These parts, similar in appearance, can be easily identified.

NOTE: Perform Step 1 through Step 8 on each side of vehicle to complete shoe set installation, then proceed to Step 9.

1. Completely retract the caliper piston back into piston bore of the caliper. This is required to gain the necessary shoe-to-rotor clearance for the caliper installation onto the steering knuckle.

2. Remove any protective paper from the noise suppression gasket on both inner and outer brake shoe assemblies (if equipped).

3. Install the inboard brake shoe into the caliper piston by firmly pressing the shoe in with the thumbs (Fig. 32). Be sure the inboard brake shoe is positioned squarely against the face of the caliper piston.

4. Slide the outboard brake shoe onto the caliper assembly (Fig. 31). Be sure the retaining clip is squarely seated in the depressed areas on the caliper.

5. Lubricate both adapter caliper slide abutments with a liberal amount of Mopar Multi-purpose Lubricant, or an equivalent.

CAUTION: Use care when installing the caliper assembly onto adapter so the guide pin bushings and sleeves do not get damaged by the mounting bosses on adapter.

6. Starting with the lower end, carefully lower the caliper and brake shoes over the brake rotor and catch the caliper's bottom edge behind the caliper slide abutment (Fig. 29). Rotate the top of the caliper into mounting position on the adapter.

CAUTION: Extreme caution should be taken not to cross thread the caliper guide pin bolts when they are installed.

7. Carefully install the caliper guide pin bolts (Fig. 28), then tighten them to a torque of 22 Nm (192 inch lbs.).

8. Install the tire and wheel assembly. Tighten the wheel mounting nuts to a torque of 135 Nm (100 ft. lbs.).

9. Lower the vehicle.

10. Pump the brake pedal to set the brake shoes to the brake rotors, then check brake fluid level in master cylinder reservoir. Adjust brake fluid level as necessary.

11. Road test the vehicle and make several stops to wear off any foreign material on the brakes and to seat the brake shoes.

______________________

Rotor Replacement

2005 Dodge Neon L4-2.0L VIN C

Rear Brake Rotor

Vehicle Brakes and Traction Control Disc Brake System Brake Rotor/Disc Service and Repair Procedures Brake Rotor - Removal and Installation Rear Brake Rotor

REAR BRAKE ROTOR

REMOVAL - REAR

NOTE: Before proceeding, Refer to WARNING/CAUTION.

1. Raise the vehicle.

2. Remove the rear tire and wheel assembly.

3. Remove the rear disc brake caliper assembly from the brake rotor and store it out of the way.

pic 6

4. Remove any clips retaining the brake rotor (Fig. 28).

5. Remove the brake rotor by pulling it straight off the wheel mounting studs.

INSTALLATION - REAR

Part 2 Of 2

pic 7

CAUTION: When installing new brake components, be sure to use correct parts. Parts designed for BR3 Performance Brake System must not be mixed with other brake systems. These parts, similar in appearance, can be easily identified (Fig. 119).

NOTE: Inspect disc brake shoes and parking brake shoes before installation.

1. Install the rear brake rotor over the wheel mounting studs and onto the hub (Fig. 28).

2. Install rear disc brake caliper and shoes.

3. Install the tire and wheel assembly. Tighten the wheel mounting nuts to a torque of 135 Nm (100 ft. lbs.).

4. Adjust the parking brake shoes as necessary.

5. Lower the vehicle.

6. Pump the brake pedal before moving the vehicle to set the brake shoes to the brake rotor.

_______________________

I hope this helps. Let me know if you have other questions.

Take care and God Bless,

Joe

Images (Click to make bigger)

Thursday, March 11th, 2021 AT 1:39 PM

(Merged)