TIMING CHAIN, SPROCKETS & TENSIONER

Tips Click a link to view tip

Tech1Tip: timing chain tensioner

NOTE:This procedure has been revised due to GM service manual update (SMU) # 00-06-01-002 dated Feb, 2000

Removal

CAUTION:To prevent severe engine damage, carefully follow procedure.

Disconnect negative battery cable. Remove front cover. See FRONT COVER . See . Rotate crankshaft in normal direction of rotation (clockwise, as viewed from front of engine) until cylinder No. 1 is at TDC of compression stroke.

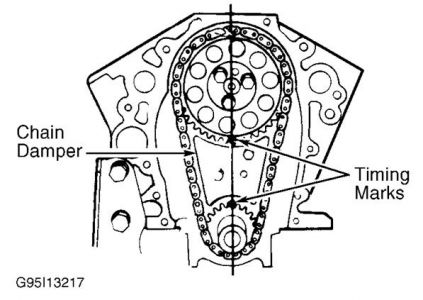

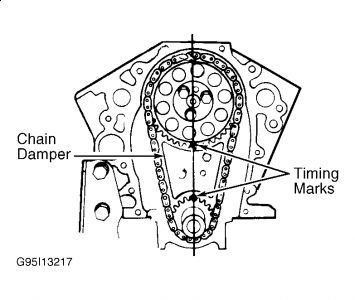

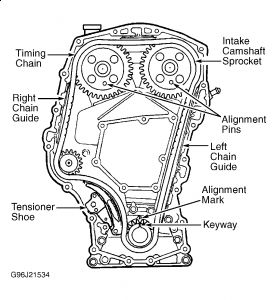

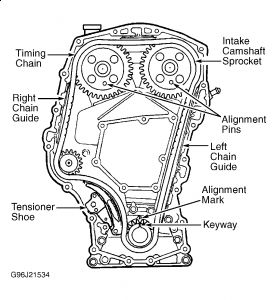

The camshaft sprocket dowel pin hole should line up with holes on timing chain housing. The crankshaft sprocket keyway should point upwards. See Fig. 7 . Remove timing chain guides. Raise and support vehicle. Make sure slack in chain is above tensioner assembly, then remove chain tensioner.

Note that timing chain must be disengaged from any wear grooves in tensioner shoe before removing shoe. Slide a screwdriver blade between chain and tensioner shoe, while pulling shoe outward (this should disengage chain from wear grooves in shoe). If timing chain is not difficult to remove, go to step 5). If it is difficult to remove timing chain shoe, go to next step.

CAUTION:To prevent damage to sprocket or timing chain housing, use a puller to remove sprocket from camshaft. DO NOT pry sprocket from camshaft.

Lower vehicle. Hold intake camshaft sprocket with Sprocket Wrench (J-39579) and remove sprocket bolt. Remove washer from bolt and rethread bolt into camshaft by hand. Remove camshaft sprocket using a 3-jawed puller. DO NOT attempt to pry sprocket off or damage will result.

Remove tensioner assembly bolts and tensioner. Mark outer surface of timing chain and crankshaft sprocket for reassembly reference. Remove timing chain.

Fig. 7: Aligning Timing Marks

Courtesy of GENERAL MOTORS CORP.

Installation

Install the camshaft sprockets. The sprockets are identical and interchangeable. Clean the old sealer off of the bolts with a wire brush. Clean the threaded hole in the camshaft with a nylon bristle brush. Coat the camshaft bolts with Adhesive/Sealant Compound (GM 1234593) or equivalent. See Fig. 8 .

Install the camshaft sprocket bolts and washers while holding the sprockets with Tool (J- 39579). Tighten the bolts to 52 ft. lbs. (70 N.m).

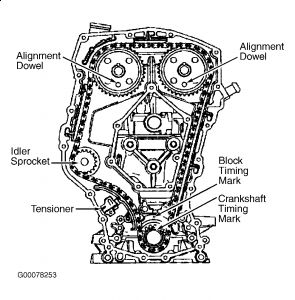

NOTE:Ensure camshaft sprocket alignment pins are in the cylinder block and the timing chain housing, prior to installing the timing chain housing. The camshaft sprocket alignment pins ensure proper chain housing and front cover location for correct front oil seat to crankshaft alignment.

Install Tool (J-36008-A) through the holes in the camshaft sprockets and into the holes in the timing chain housing. This will position the camshaft for correct timing. Use the following steps if the camshafts are out of position and must be rotated more than 1/8 turn in order to install the alignment dowel pins:

The crankshaft must be rotated 90 degrees clockwise from TDC to give the valves adequate clearance to open.

Once the camshafts are in position and the dowels are installed, rotate the crankshaft counter clockwise back to TDC.

CAUTION:DO NOT rotate the crankshaft clockwise to TDC. Valve or piston damage could occur. The timing chain and crankshaft sprocket must be put in a specific direction for chain noise and wear considerations. The surfaces that were marked during removal should be showing when the chain and crankshaft sprocket are installed.

Install the timing chain over the exhaust camshaft sprocket around the coolant pump sprocket and around the crankshaft sprocket. Remove the alignment dowel pin from the intake camshaft. Use Tool (J-39579) in order to rotate the intake camshaft sprocket counter clockwise enough to allow the timing chain to slide over the intake camshaft sprocket. Release Tool (J-39579). The length of the chain between the two camshaft sprockets will tighten.

If properly timed, the intake camshaft alignment dowel pin will slide in easily. If the dowel pin does not fully index, the camshafts are not timed correctly and the procedure must be repeated. Leave the alignment dowel pins installed. The keyway on the crankshaft and the mark on the cylinder block should be aligned when the slack is removed from the chain between the intake camshaft sprocket and the crankshaft sprocket. If the mark and the keyway are not aligned, move the chain one tooth forward or rearward. Remove the slack and recheck the marks.

NOTE:Use the following steps in order to reset the timing chain tensioner assembly to the zero position:

Reset the timing chain tensioner assembly.

Insert the tensioner plunger assembly into the tensioner housing.

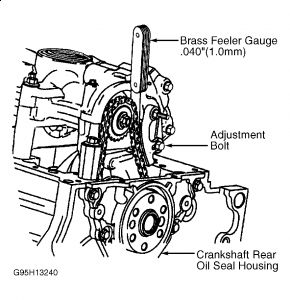

With the tensioner plunger fully extended, turn the complete assembly upside down on a bench or other flat surface. See Fig. 9 .

With the plunger face against the workbench, press firmly on the bottom of the tensioner housing.

Compress the plunger until the plunger is seated flush in the tensioner. See Fig. 10 .

Check the plunger to ensure the plunger is out of the cylinder at the correct dimension. The correct dimension for the plunger to extend out of the cylinder is .070" (1.7 mm) maximum. See Fig. 10 . Loosely install the tensioner assembly and bolts to the timing chain housing. See Fig. 11 . Install the timing chain tensioner shoe on the stud. Apply hand pressure to the timing chain tensioner shoe until the locking tab seats in the groove in the stud. Tighten the timing chain tensioner bolts. DO NOT over tighten. Tighten the bolts to 89 INCH lbs. (10 N.m).

CAUTION:If the timing chain tensioner plunger is not released from the installation position, engine damage will occur when the engine is started.

Release the timing chain tensioner plunger using the following procedure:

Using a flat blade screwdriver, cotter pin remover, or a similar tool, press firmly against the face of the timing chain tensioner plunger. See Fig. 12 .

NOTE:If the timing chain tensioner plunger cannot be depressed, the plunger is not properly reset and the procedure for resetting the timing chain tensioner should be repeated.

Depress the timing chain tensioner plunger until the plunger is bottomed out in the bore of the timing chain tensioner. See Fig. 10 .

Release the tensioner plunger. See Fig. 12 . The plunger should press firmly against the back of the timing chain tensioner shoe. Remove Tool (J- 36008-A) from the camshaft sprockets.

CAUTION:Beginning with the 1998 model year, the timing chain on the LD9 (VIN T) Twin Cam Engine is different from the chain found on earlier versions of this engine, and is not to be replaced with a timing chain from earlier model year engines. The timing sprockets were also changed beginning in 1998, and the shape of the chain links matches the sprockets. Engine damage may result if the wrong timing chain is used. The timing chain and the crankshaft sprocket must be marked so that they are reinstalled in the same side facing out at the time of assembly.

Rotate the crankshaft clockwise two full rotations. Align the crankshaft keyway with the mark on the cylinder block and reinstall the alignment dowel pins. The alignment dowel pins will slide in easily if the engine is timed correctly. Install the timing chain guides.

Friday, February 12th, 2021 AT 1:31 PM

(Merged)