You didn't list an engine size. If this is an interference engine, 12 teeth can be enough to cause bent valves.

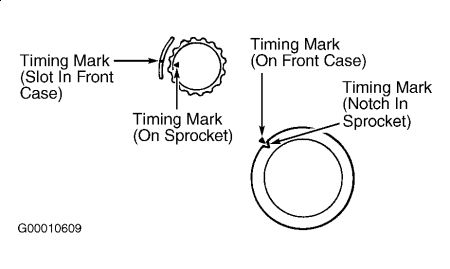

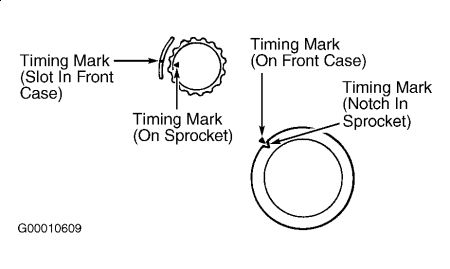

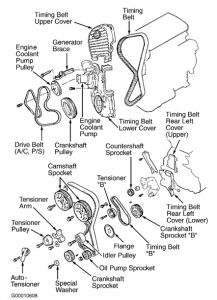

As far as getting each sprocket set to the proper position, welcome to our world! When you loosen the timing belt, the crankshaft will stay where you put it, but the camshafts will usually rotate due to the pressure from the valve springs. Also be aware that if you do have an interference engine, you may not be able to turn a camshaft to top dead center if the piston is already there. Instead, rotate the crankshaft backward about a sixth of a revolution. That will insure no piston is at top dead center and no valves can be hit and bent. Place the camshaft sprockets to their marks and do something that will hold them there. Now bring the crank forward to TDC, and slide the belt on. The slack in the timing belt will always be taken up on the back side. The length of that part of the belt can vary and is not important. It's the length on the front, where it is pulling on the cam sprockets, that is critical for proper valve timing. Start installing the belt toward the front so it is tight and the sprockets haven't moved. Keep whatever slack develops in the rear where the tensioner will take it up.

Once the belt is tightened, rotate the crankshaft forward two full revolutions by hand, then recheck the timing marks. Always turn it in the normal direction of rotation. Don't be surprised if one of the camshaft sprockets is off a tooth or two. You'll need to loosen the belt and move it on that sprocket. This happens to us all the time.

Wednesday, October 3rd, 2018 AT 7:47 PM

(Merged)