Saturday, April 7th, 2012 AT 3:58 AM

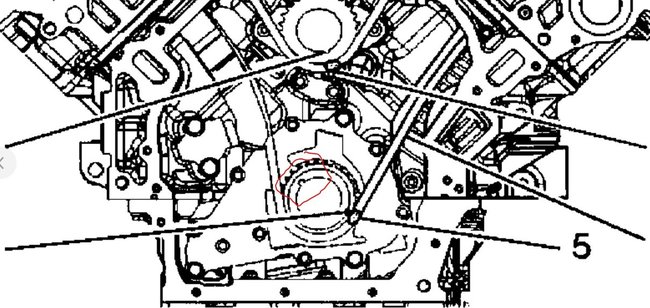

Trying to replace the Crankshaft Position Sensor on a 3800 engine by myself. No luck in getting an assistant, nor any luck obtaining the GM recommended flywheel tool. Loosening the pulley bolt is much of an issue, but its more of torqueing the bolt 110 pounds plus an additional 76 degrees. Any suggestions will be greatly appreciated.