A little bit about the car:

1998 Honda Accord LX 4Door

2.2Liter VTECH engine with Automatic Transmission

240,000+ miles

Car just had all the seals rear, main and transmission replaced about 2-3 weeks ago. It was leaking oil.

The car has ran fine without any issues thus far until last night. I was driving as I normally do nothing out of the ordinary maybe going a bit slower than usual because of traffic and the car sputtered just for a second and went away. So I didn’t read much into it until about 10-15 minutes later I was going about 10mph and the car died. All the lights came on just as it does when on accessory 2 along with the check engine light. Luckily I was able to park the car out of the way. So without even turning off the car I put it in park and attempted to start it but it wouldn’t start just act like it wanted to but nothing. So I turned it off and opened the hood to see if I could see anything out of the ordinary and I didn’t and got back in the car and started it up without issue. So I put it in reverse and attempted to back out of the position I was in and then put it in park and attempted to move when it started sputtering again and wanting to stall. I decided at this point to leave it and walk to my destination, which was about a mile a way. When I got back to the car about 2.5 hours later it started without issue again but when I put it in drive and gave it gas it started sputtering again and stalled so I attempted to start the car by putting it in neutral and cranking the engine, This did not start the car (BTW the car is coasting on the road at this point) so while it was still in neutral I moved the key back to accessory 1 and the car started back up without hesitation. But when I applied gas it wanted to stall and sputter but somehow I kept it going and was able to get up to 50mph and stayed there pretty consistently while driving home. While I was driving the car did sort of hesitate and seem like it wanted to stall sputter and die again but didn’t until I got closer to home and had to slow down. When it stalled on me I did the same thing where I put it in neutral and moved the key to accessory 1 and the car started without a problem but wanted to stall again when accelerating trying to get home. Finally got the car home and called my brother-in-law who is a mechanic to see if I could get him to look at it.

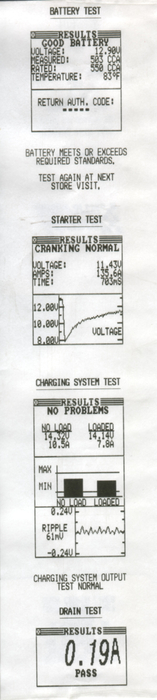

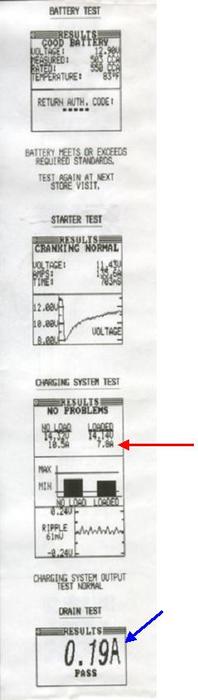

He came out the next day and connected his work scanner to the car and received and error code of P0336. So he checked a couple of things on the car and said all looked ok. (BTW he was the one who replaced all the seals on the car) So we took the car for a spin around the block. And once again the car started without issue. We got about ¾ of a mile around the block and the car started doing its thing. I would apply the gas petal and it would want to stall and sputter. On this trip we noticed several things. 1- the car did not want to go any further than 3000 RPM no matter how much gas I applied. 2- the electrical reading on the car with the code checker still attached was reading 12v and seemed to be running off the batter only but then would go away. So we got back home and did some more testing and found out still after resetting the codes that when the car stalled in accessory 2 the key still needed to be put back to accessory 1 before it would start. He also connected a spark plug tester thing (sorry not sure about the name, one end went into the spark plug well and the other end went into the spark plug wire and there was a flashing light in the middle. He said that this was good. We also tested the alternator with a voltmeter and it seemed ok. Then we got in the car and started the car again and this time turned all kinds of stuff on A/C, radio, turn signal, high beams and placed the car in park and all seemed ok at about a 1000RPM but when we turned off the A/C the car tried to sputter again. We have checked the fuel pump and ignition switch and they OK. The car just wants to stutter and die when gas is applied even while in park. Any suggestions or help would be appreciated on this. He is concerned of a false positive on the error codes and does not want to throw parts at it to fix it.

Thursday, May 31st, 2012 AT 5:07 PM