It looks easy but it has to be set along with the TPS, it works off TPS voltage. 1. Remove air cleaner. Disconnect and plug vacuum hoses at air cleaner thermal vacuum valve, EGR, canister purge and ILC.

2. Back off idle stop screw 3 turns.

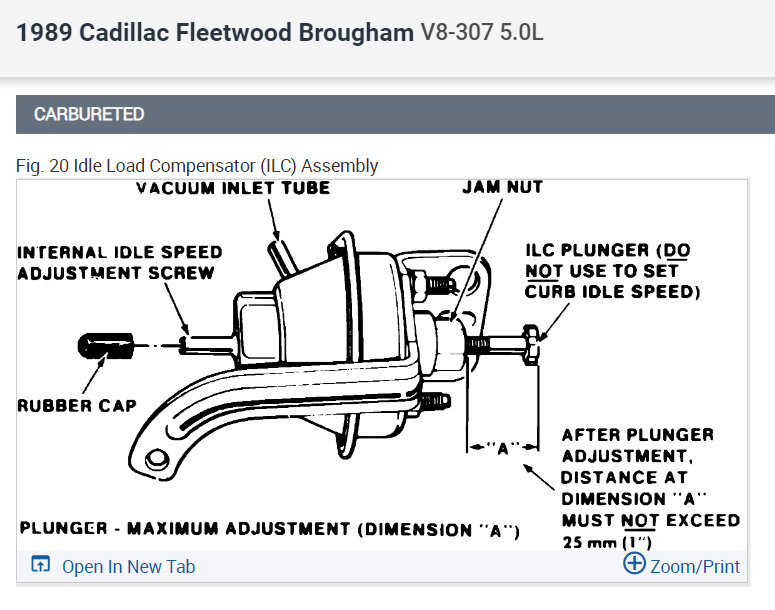

3. With A/C "OFF, " engine warm, choke open, transmission in drive and ILC fully extended (no vacuum) use tool J 29607 or B T8022 (or equivalent) to adjust plunger to obtain 700 RPM +/- 50 RPM. A wrench must be used to hold jam nut to prevent damage.

4. Measure distance from the plunger tip to the jam nut. If distance is more than 1 inch (25 mm), for cause of low idle speed, refer to Diagnosis by Symptom found under Computers and Control Systems/System Diagnosis. See: Computers and Control Systems > Testing and Inspection

5. Reconnect vacuum hose to ILC and note RPM. It should be 450 +/- 50 RPM. If OK reconnect all vacuum hoses, reinstall air cleaner and test drive vehicle. If not OK proceed with next step.

6. Turn ignition "OFF" and remove idle load compensator or modify a 3/32" (0.090") hex wrench to clear obstructions.

7. Remove rubber cap from center outlet tube.

8. Insert hex wrench into center tube on rear of ILC.

9. One turn of the hex wrench changes idle speed 75 to 100 RPM. Turning wrench clockwise lowers RPM, counterclockwise increases RPM. Adjust as necessary and reinstall plug on center outlet tube.

10. Reinstall ILC, throttle return spring and other components as necessary and recheck idle speed. If needed repeat steps 7-9. Disconnect battery cable or power supply to ECM to reset TPS value to ECM.

11. Apply vacuum to ILC to retract the plunger. Adjust idle stop screw until 450 RPM is obtained with transmission in drive.

12. With ignition "OFF" reconnect all vacuum hoses, install air horn gasket and air cleaner.

Check out the images (below). Please let us know what happens.

Image (Click to make bigger)

SPONSORED LINKS

Thursday, October 21st, 2010 AT 6:36 PM