Welcome to 2CarPros.

The first thing I recommend is to scan the computer for diagnostic trouble codes. Here is a quick video showing how that is done:

https://youtu.be/YV3TRZwer8k

I realize most people don't own a scanner. If that is the case, most parts stores will do it for free, so have that done.

Next, I need to know if this is a 3.5L V6. I don't believe a 4 cylinder was offered.

Now, based on your description, my first suspect is a plugged catalytic converter. Take a look through these links. The last link describes how to check a converter.

https://www.2carpros.com/articles/bad-catalytic-converter-symptoms

https://www.2carpros.com/articles/how-to-test-a-catalytic-converter

___________________________________

Next, I would suggest checking the fuel pressure to confirm there isn't an issue with the regulator causing pressure to get too high.

Here is a link that shows in general how it is done:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are the directions and specifications specific to your vehicle. The attached pictures correlate with these directions.

_______________________________________________________________

COMPONENT TESTS AND GENERAL DIAGNOSTICS

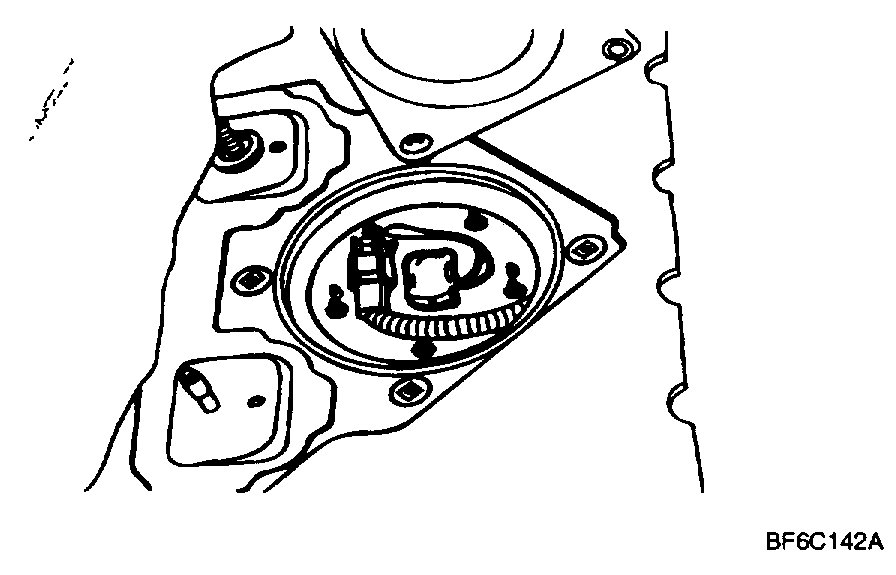

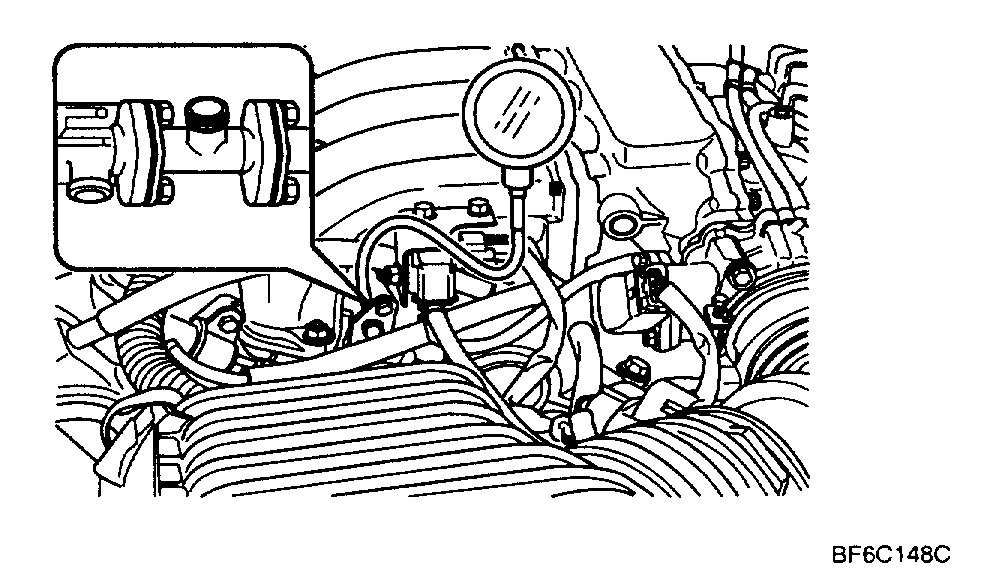

picture 1

1. Reduce the internal pressure of the fuel pipes and hoses by the following procedures.

Disconnect the fuel pump harness connector in the rear seat side.

Start the engine and, after it stops by itself, turn the ignition switch to the OFF position.

Disconnect the battery negative (-) terminal. Connect the fuel pump harness connector.

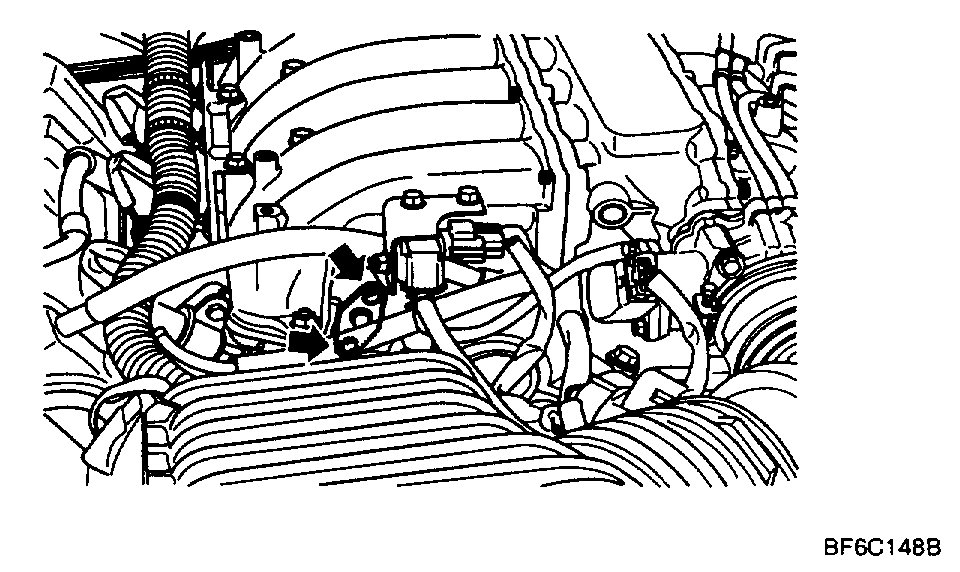

picture 2

2. Disconnect the fuel high pressure hose at the fuel line side.

CAUTION: Cover the pipe connection with a shop towel to prevent splashing of fuel caused by residual pressure in the fuel line.

3. Using the Fuel Pressure Gauge Adapter, install the fuel-pressure gauge to the fuel high pressure hose.

Fuel Pressure Gauge Adapter - P/N 09353-3800

4. Connect the battery's negative (-) terminal.

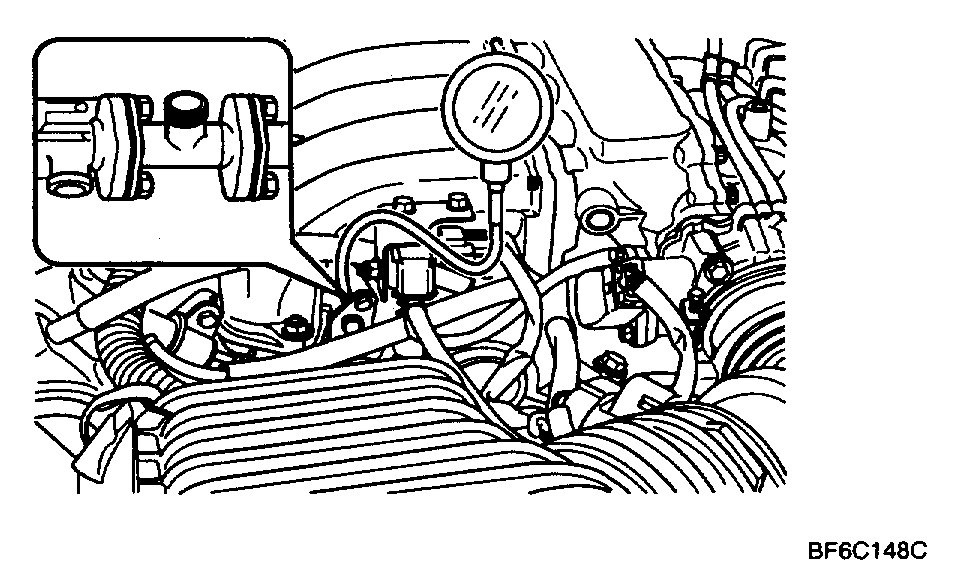

picture 3

5. Apply battery voltage to the fuel pump drive terminal, activate the fuel pump; then, with fuel pressure applied, check that there is no fuel leakage from the pressure gauge or connection part.

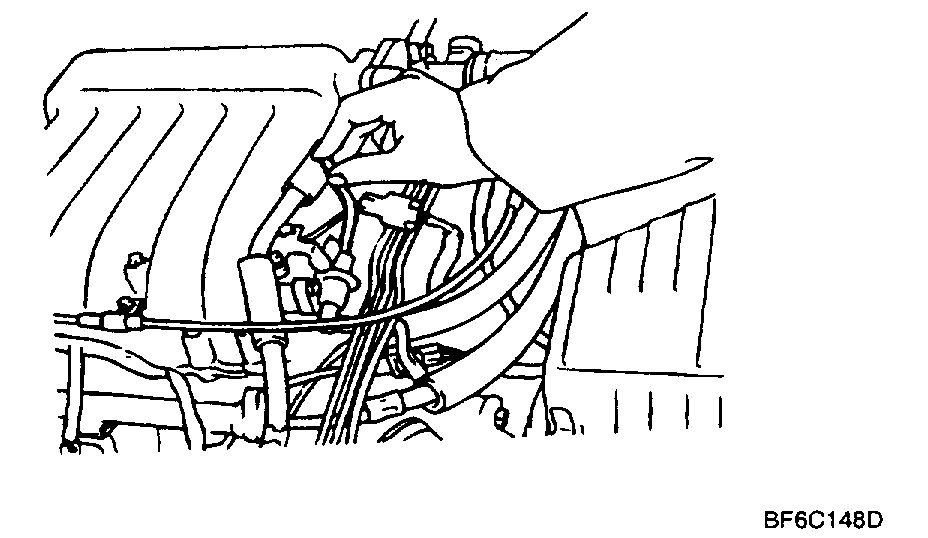

picture 4

6. Disconnect the vacuum hose from the pressure regulator and plug the hose end. Measure the fuel pressure at idle.

Standard value: 320 - 340 kPa (3.26 - 3.47 kg/sq.cm, 46 - 49 psi)

picture 5

7. Measure the fuel pressure when the vacuum hose is connected to the pressure regulator (while engine is running).

Standard value: Approx. 270 kPa (2.75 kg/sq.cm, 39 psi)

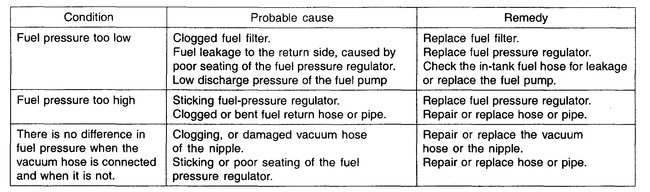

Condition/Probable Cause

picture 6

8. If the results of the measurements made in steps (6) and (7) are not within the standard value, use the table to determine the probable cause, and make the necessary repairs.

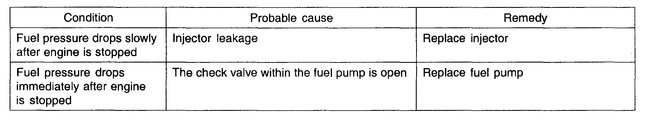

picture 7

9. Stop the engine and check for a change in the fuel pressure gauge reading, which should hold for approximately 5 minutes. If the gauge indication drops, observe the rate of drop. Determine and remove the causes according to the table.

10. Reduce the fuel pressure in the fuel line.

11. Disconnect the high pressure hose and remove the fuel pressure gauge.

CAUTION: Cover the pipe connection with a shop towel to prevent splashing of fuel caused by residual pressure in the fuel line.

12. Install a new O-ring at the groove in the end of the high-pressure hose.

13. Connect the high pressure fuel hose to the delivery pipe, and tighten the screws to the specified torque.

Tightening torque

High pressure fuel hose to delivery pipe:

3 - 4 Nm 30 - 40 kg.cm, 2.2 - 3 lb.ft

14. Check for fuel leaks.

Apply battery voltage to the fuel pump drive terminal to operate the fuel pump.

With pressure, check the fuel line for leaks.

The first thing to do is scan the computer. Once you have that done, let me know what code is found. Please keep in mind, there are other things that can cause this. However, smelling the fuel and power loss leads me to believe there is a restriction. It could also deal with a fuel regulator issue.

Let me know what you find or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Wednesday, April 3rd, 2019 AT 8:54 PM