Introduction

An alternator is designed to supply electrical power (13.6 to 14.6 volts) to a vehicle when the engine is operating to recharge the battery back up for future use. This is done using the rotational energy of the engine transferred by the serpentine belt to the front pulley of the alternator. While the engine is running the alternator supplies electrical power to the car's accessories such as the lighting system, engine computer, HVAC system and windshield wipers as well.

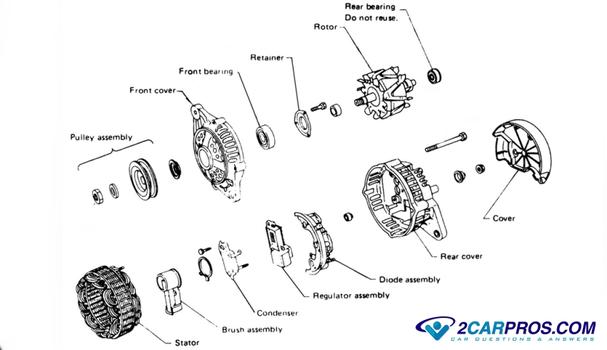

This is achieved by the rotating mass called a "rotor" which sits inside the windings that is the stationary inside the alternator housing called a "stator" which produces electrical energy through electromagnetic induction.

There is a rectifier plate which has six diode assemblies that help convert alternating currant (AC), which is the voltage "type" the alternator produces, and changes it to DC voltage which is needed to run the car and charge the battery.

An internal voltage regulator monitors and adjusts the alternator voltage/amperage output to the battery and electrical system, (Note: Some older cars will have an external voltage regulator).

Here is what a typical alternator looks like:

A serpentine belt is used to deliver rotation energy from the engine via the main drive pulley.

A large power terminal is used as the main voltage feed to the electrical system which is usually connected to the positive battery post or fuse box.

This main power feed is used to power circuits throughout the vehicle.

Most units are designed with a built in voltage regulator which help stabilize the voltage output. A wiring harness connector is used by the computer PCM to control and monitor the voltage regulator during variable engine speeds (RPM's) and voltage demands.

The alternator works on the principle of electromagnetism, by turning the magnetic armature inside a wire field which has been electrified to produce AC (alternating currant) voltage. A series of diodes (6) convert AC to DC voltage which is needed for the electrical system. An armature is supported by two roller bearings on either end of the alternator housing, voltage is transferred to terminals at the rear of the housing via a spring loaded brush set.

Helpful Information A common alternator problem is undercharging, this condition is often accompanied

by symptoms such as a battery warning light, low state of battery charge, poor or erratic

performance from electrical components. Common Problems Best Practices This guide knowledge base was created by the 2CarPros Team, and by

Ken Lavacot: Automobile repair shop owner and

certified master automobile technician of over 30 years. If you have question or

need help please ask one of our experts we are happy

to help. Please visit our 2CarPros

YouTube Channel.

Credits