Introduction

The clutch assembly is mounted to the flywheel, which is located between the engine and transmission. The clutch disc is designed to disengage, and then re-engage power from the engine to the transmission so you can start off, change gears and stop the car without the engine stalling. This guide will take you through the detailed workings of an automotive clutch, explaining each part’s function and how the clutch system operates to engage and disengage power.

Clutch Assembly:

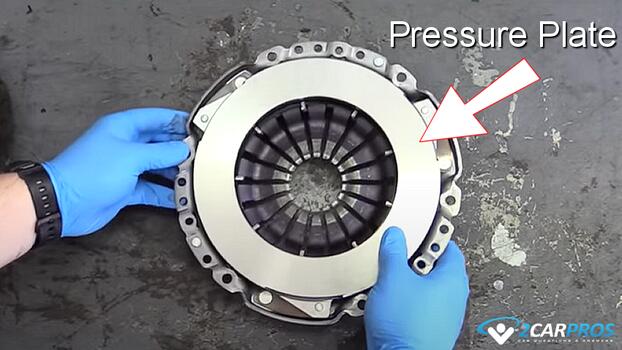

- Clutch pressure plate

- Clutch disc

- Pilot bearing (rear wheel drive cars only, typically).

Release Mechanism:

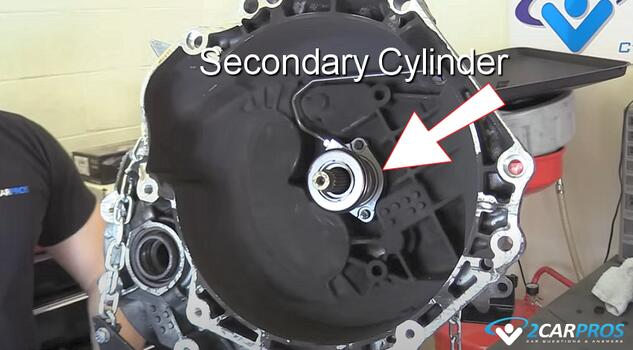

- Throughout bearing - Secondary cylinder

- Clutch master cylinder

- Clutch Pedal

- Clutch cable (some cars)

- Hydraulic line

How the Clutch Works

1. Clutch Disc: The clutch disc is fitted between the flywheel, and the pressure plate, which is lined with a metallic/asbestos material much like a brake pad. This lining eventually wears out and the clutch starts to slip, this is why the clutch is normal wear item. When a vehicle is in gear but stopped, the flywheel and pressure plate rotate at engine speed while the clutch disc is not spinning, allowing you to shift gears without grinding. Here is what a typical clutch disc looks like:

2. Clutch Pressure Plate: Is the other main part of the clutch assembly, which is bolted to the engine flywheel and holds pressure against the clutch disc (engaged) which in-turn transfers engine power to the transmission's input shaft, this is the part where the throwout or release bearing rides on.

3. Pilot Bearing: This bearing is uses to support the opposite end of the standard transmission input shaft and is located in the center of the engine flywheel, which is typically used on rear wheel drive cars only.

Release Mechanism

A clutch is naturally in the engaged mode by default, when the engine is running the clutch must be disengaged or the engine will stall out, (unless in neutral) or you will not be able to shift any gear. The following is how the disengagement process works:

1. Clutch Master Cylinder: The clutch pedal is connected to a clutch master cylinder, which produces hydraulic pressure when the pedal is pushed downward. Much like a brake master cylinder, it uses brake fluid to operate and will have a fluid reservoir under the hood. A small hydraulic line runs from the clutch master to the secondary cylinder.

2. Clutch Secondary Cylinder The secondary cylinder can be located in two different positions near the front of the transmission, either it will bolt to the outer part of the transmission bell housing and use a clutch fork to operated the throwout bearing, or it will be integrated into throwout bearing which is mounted to the transmission input shaft bearing retainer, (more popular).

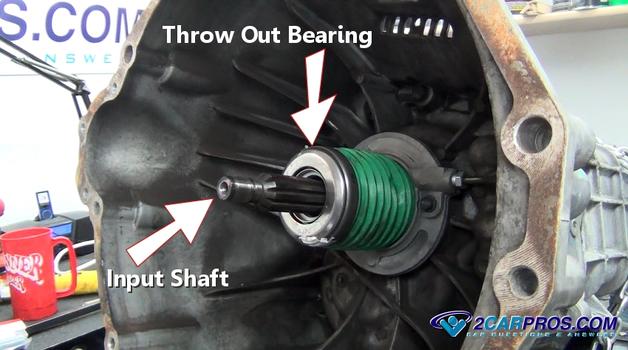

3. Throwout Bearing: This bearing is used to ride against the pressure plate fingers and actuate the clutch assembly. When the secondary cylinder is actuated, it forces the throwout bearing against the pressure plate fingers pushing them inward which releases the clutch disc.

4. Clutch Cable: Some manufactures use a clutch cable in place of the hydraulic system to release the clutch via the throwout bearing and clutch fork.

Conclusion

This is a picture of a cutaway so you can see what the clutch assembly looks like all together.

Here is what the throwout bearing position looks like inside the transmission bell housing.

The clutch disc is lined with friction material that allows it to grip the flywheel effectively. However, this friction is not instant, it requires careful modulation of the clutch pedal during engagement, especially when starting from a standstill, to prevent the vehicle from stalling or jerking.

Watch the Video!

Please watch this video of how you can tell if the clutch is bad to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.