Introduction

A throwout bearing/secondary cylinder is used to apply force against the clutch pressure plate to release the clutch disc and should be replaced as part of the normal clutch job. Its a good idea to see how a throwout bearing works in its relationship to the clutch, so you can fully understand it's importance. The throwout bearing sits inside of the transmission's bell housing and is held in place by a clutch fork or a secondary cylinder.

Note: The throwout bearing and secondary cylinder are a combination part and are serviced together in most cases.

Note: The standard transmission will need to be removed before this job can be performed.

Tools and Equipment Needed

- Socket wrench set

- Torque wrench

- Penetrating fluid (for stuck bolts)

- New throwout bearing/secondary cylinder

- Brake cleaner

- Rubber gloves

- Safety glasses

- Air respirator

WARNING: In this job you will have contact with asbestos so use precautions!

Throwout Bearing/Secondary Cylinder Replacement Guide

1. Remove Retainer Clip: Use a pair of needle nose pliers to remove the secondary cylinder hydraulic line retainer clips which will free the metal fluid line from the bell housing.

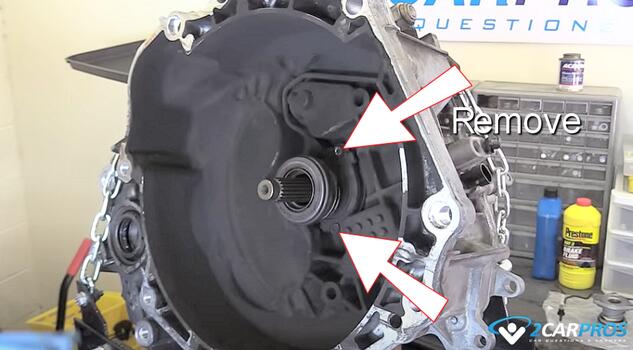

2. Remove Mounting Bolts: There will be three or four mounting bolts that hold the throwout bearing and secondary cylinder to the transmission bell housing that need to be removed, in this example the bolts are a 35 torx bit.

3. Remove Throwout Bearing/Secondary Cylinder: Grasp the bearing/cylinder firmly and pull outward from the input shaft bearing retainer, you may need to remove a plastic clip which supports the hydraulic clutch line. At this point the bearing may already be in pieces if it has failed, be sure to remove all remaining bearing parts. Match the old bearing/cylinder to the new part which should match identity.

4. Installation Preparation: Before installing the new bearing use brake spray cleaner and clean the sliding surface of the bearing retainer, once the surface is clean apply a small amount of grease to the input shaft bearing retainer to allow the throwout bearing to slide freely, (if applicable).

5. Install New Throwout Bearing/Secondary Cylinder: Install the new part and hand thread the mounting bolts to avoid cross threading. Using a socket evenly tighten the mounting bolts to factory specifications which is usually between 7 to 12 foot pounds. Reinstall any plastic clips that were removed in the process to re-secure the hydraulic line. Spin the bearing by hand to make sure it moves freely and with no irregular noises. The new bearing and cylinder is ready for the transmission to be reinstalled.

6. Refill Clutch Fluid: Under the hood of the car, remove the cap to the fluid reservoir and add brake fluid (brake fluid is the same as clutch fluid) to the full line and reinstall the cap.

7. Final Steps: When the job is complete you will need to pump the clutch pedal several times to adjust and bleed the system. There is no bleeder screw used on the salve cylinder, (most cases). Because of the location of the slave cylinder the system will self-bleed as air bubbles naturally rise to the top and out into the clutch master cylinder reservoir. Recheck the fluid level throughout this process. Continue to pump the pedal until normal pedal operation returns and you are all set.

Pro Tip:

- Do not install a throwout bearing dry or it will cause the bearing to seize hindering the clutch operation. It will also make the clutch pedal hard to push downward.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.