Automotive combustion engines require either a timing chain or belt to keep the camshaft to crankshaft correlation correct as part of the design of the engine. A timing belt is more common in overhead camshaft engines and is constructed of a fiber reinforced rubber belt with vertical cogs vulcanized to the inside. When a timing belt fails it will remove the cogs that keep the engine in-time which will stop the engine from running. Much like a timing chain there are timing marks on the crankshaft and camshaft of the engine which denote the position of each when the belt is installed. In the image below you can see how a typical timing is configured on a Volkswagen engine.

This image was taken at a car show in Los Angeles, California. The timing belt

is routed at the crankshaft, through the water pump, onto the fuel injection pump

and finally around the camshaft, the belt slack and tension is controlled by the

timing belt tensioner.

The timing belt tensioner is used to hold pressure on the belt which is spring

loaded, oil pressure activated or set manually and when released facilitates the

removal of the timing belt.

The timing belt cogs (teeth) are what drive each accessory, both the smooth side

and the cog side is used depending on the item, a water pump which does not need

to be "set" in time with the engine is driven on the smooth side.

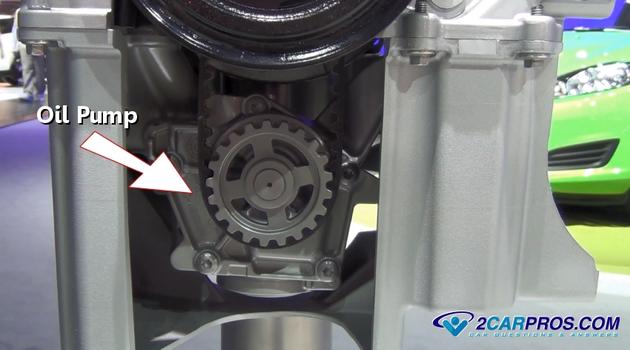

Depending on design there can be an auxiliary timing belt which is smaller and

can be used to drive a water or oil pump as in the image below.

Questions?

Our certified technicians are ready to answer car repair questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.