I like the "daring" approach of yours dear Steve. I may need to shed more light on what accompanies this sickening malfunction if you allow me please, your suggestions are all welcome by me and I will care to carry them out soonest.

I went far somehow in trying to diagnose the problem:

1. Just this afternoon I took the passenger seat off and tried to see if the black -ve wire for the FP is loose there, all I saw was some sleeve housing 3 wires( thick gray, black and green. They were going towards the cradle that includes the PRNDL lever spacing the 2 front seats apart. I took the trouble to do that because every time my wife be escorted by me, the car would be giving us a hell of stubborn cranking with no start and even as it stars after several cranking it just stalls soon. Once I drop my wife to her gym it is as if a Genie was there and got out of the bottle! Finding nothing suspicious, I secured the seat two hours ago.

2. The engine would stall when the car is stationary, moving slowly, moving at some 120 km/hr, there is no specific pattern but I mentioned the u-turn thing because that is the worst moment of all, it happened some 8-10 times so far versus some 100+ times while driving straight. 3 technicians tried a hell of tricks and jumpering this wire to that of a neighboring relay (those 4 relays), it would succeed for an hour or two but then all of a sudden it gets back to the irksome stalling.

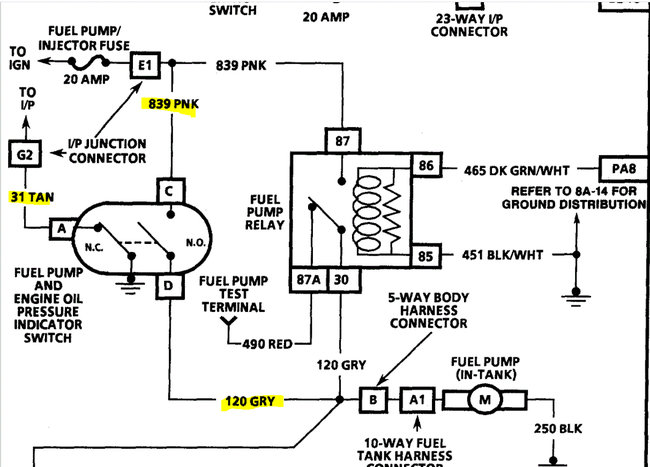

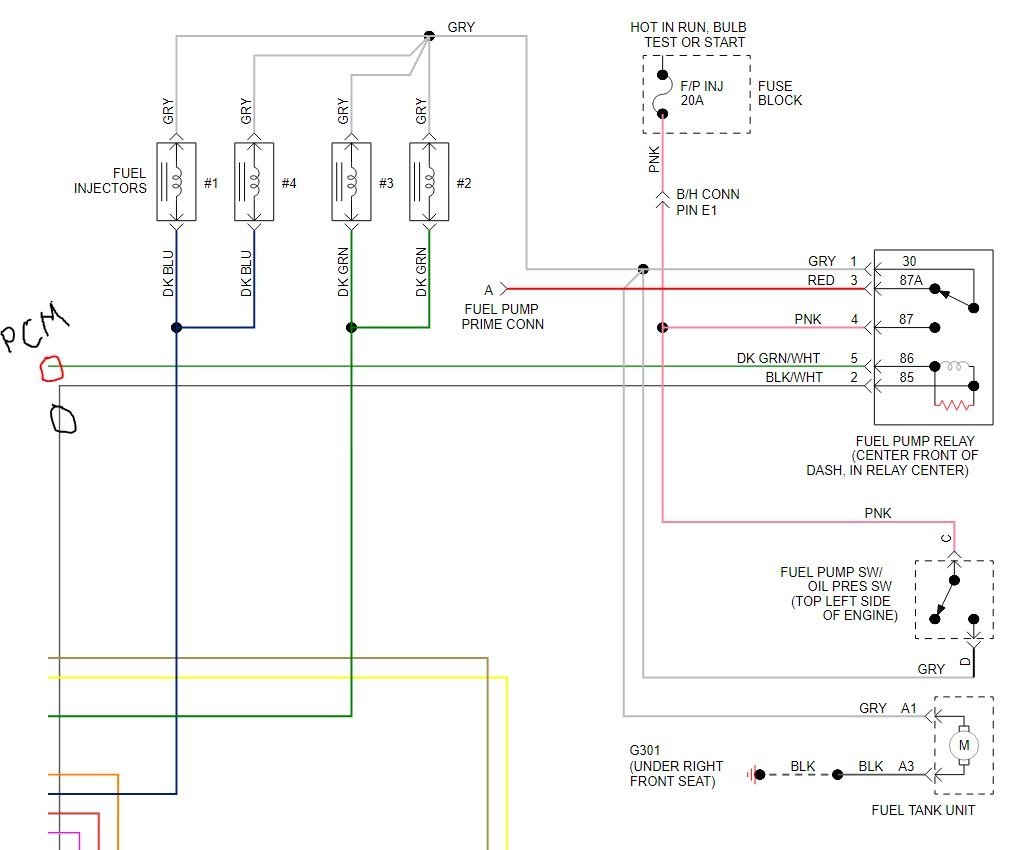

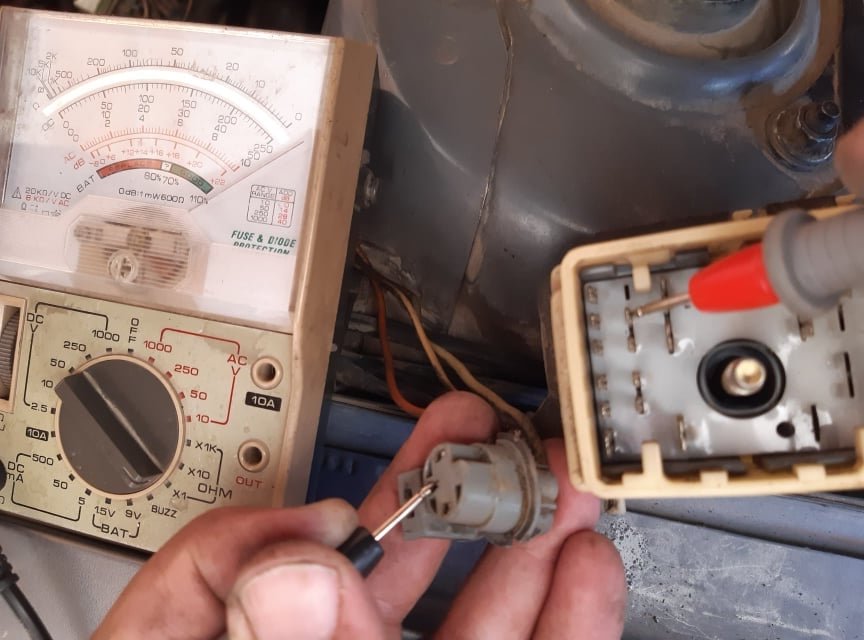

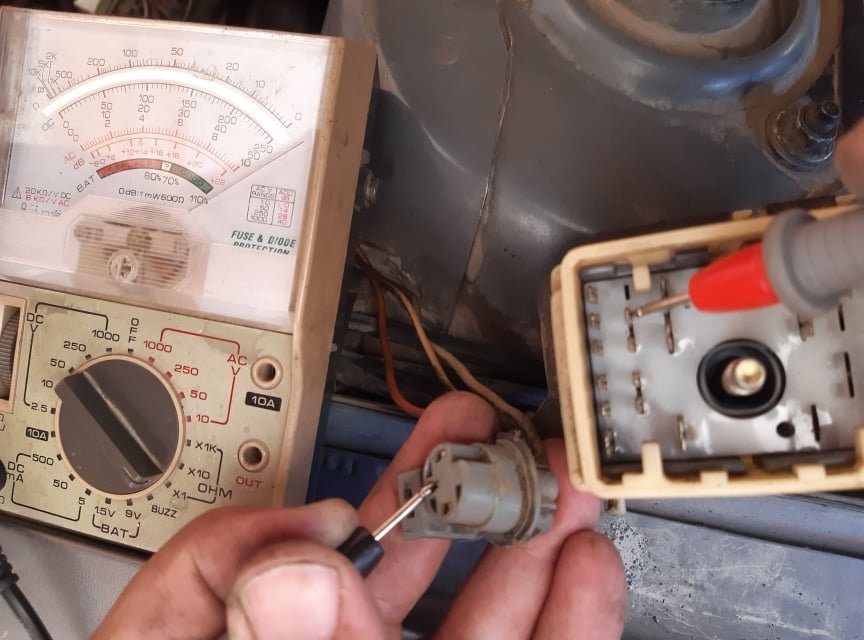

Another try: Continuity test proved positive for the Grey wire ( No. 120) with all these pins in the 12-pin pink connector of the PCM: Black/white - Tan/white and tan. At the same time of the test, continuity was positive for the following pins in the neighboring 16-pin pink connector of PCM: Blue- black stripes - green and red striped with either black or dark blue.

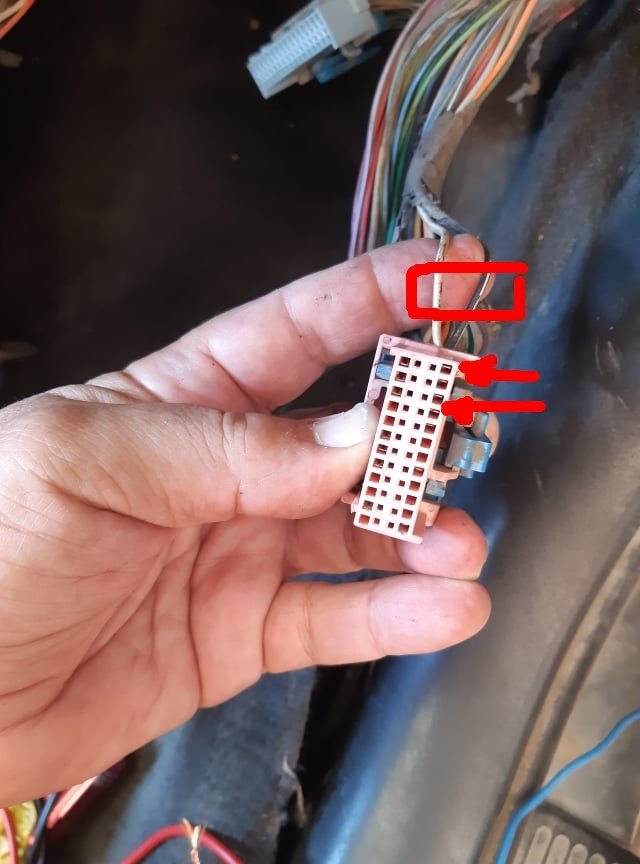

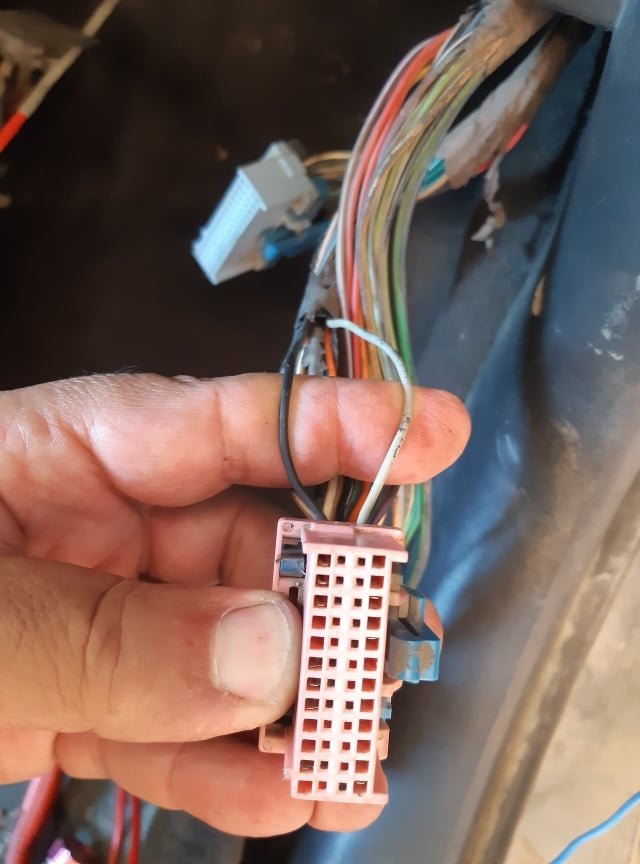

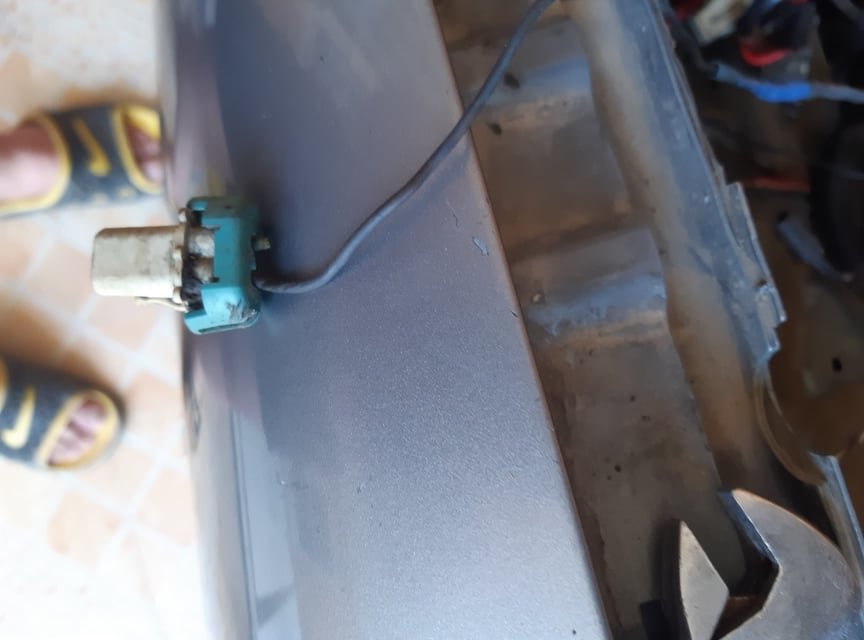

The schematic you marked for the PCM two wires (attached here once again) shows a 2-pin connector for the Oil Pressure switch/Fuel Pump switch but my engine has a 3-pin connector (1st image attached here).

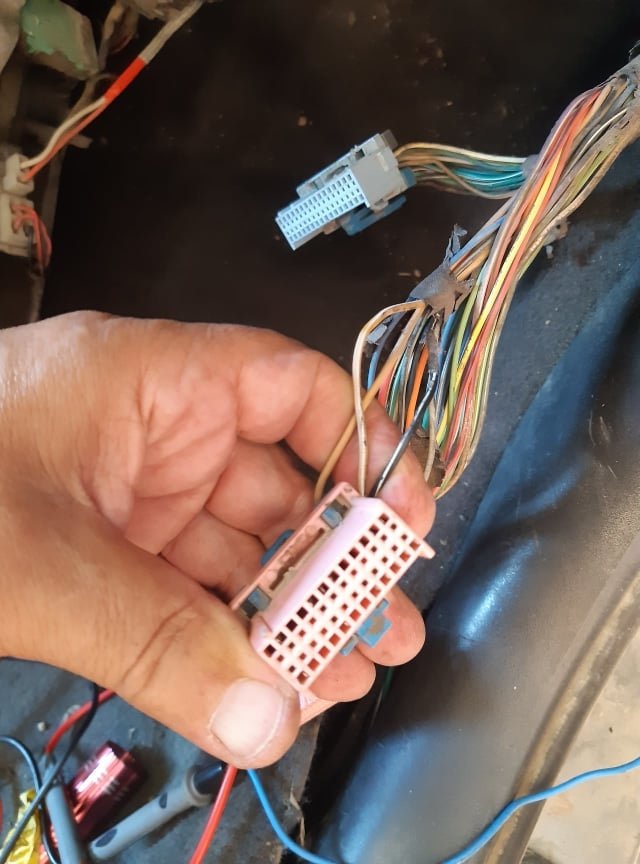

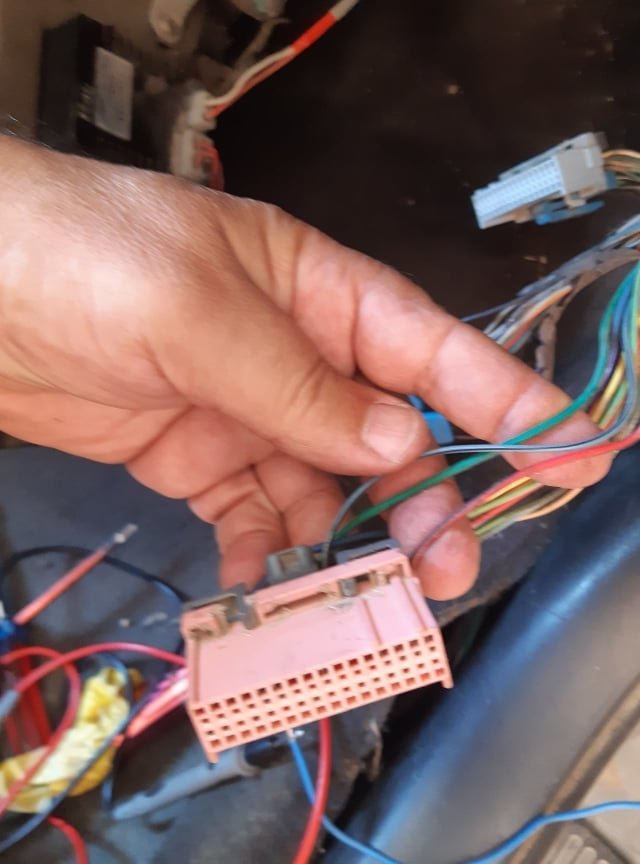

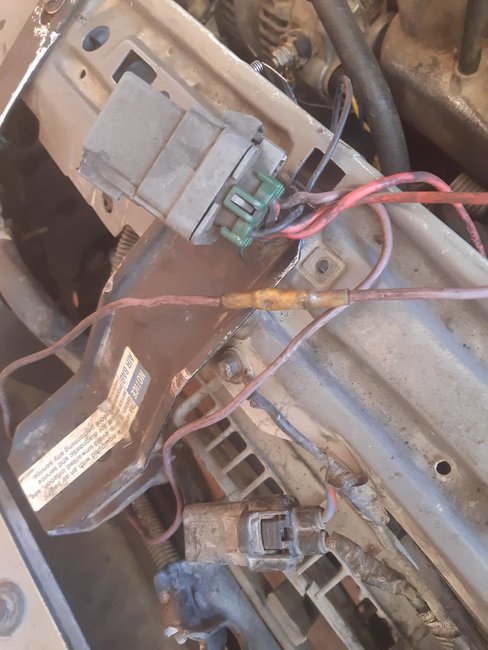

A yet other check: Continuity proved positive between a dark purple wire ( within the main harness in engine compartment) and both two pins in the 12-pins pink connector of the PCM: Black and gray (2nd image attached here).

Is it normal that one wire in the engine compartment corresponds to 2 or 3 wires that all have no color like that in the compartment?

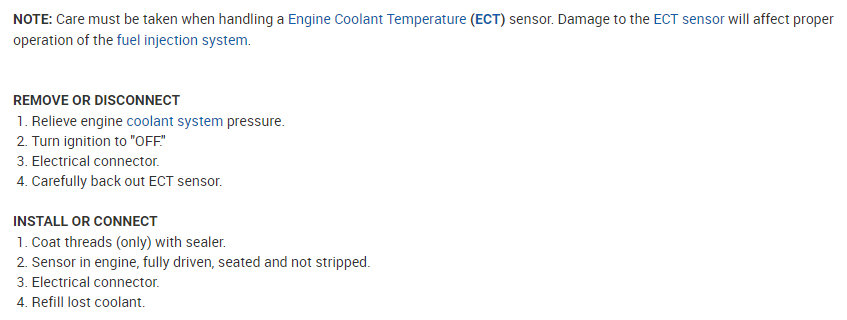

The 4th attachment is for the 3-pin/wire connector of the Oil Pressure switch/Feed Pump switch (tan - gray and pink). This connector used to cause problems to my engine, I replaced it and it was one of the steps that made the engine recover before diving once again into malfunctioning and stalling.

Images (Click to make bigger)

Thursday, July 15th, 2021 AT 2:07 PM