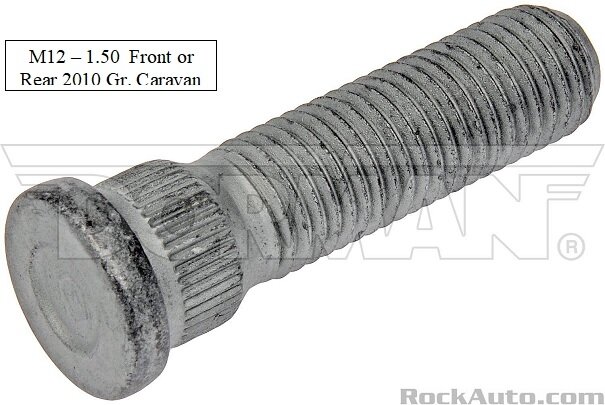

Sounds like you're referring to the wheel stud. Check the photo below. The listed time is 0.3 hours for each stud, but that may not include the time to drive the vehicle in, remove the wheels, and do the paperwork. The part is available at any auto parts store. They may go by application, but if they look up the size and go by that, I included that on the top left of the photo.

Any mechanic can replace wheel studs, but for liability reasons, some shops will only replace the entire wheel bearing assembly. There have been some really crazy lawsuits, (one ironically involving a Grand Caravan), with outrageous verdicts, so now we all pay for it. Replacing the complete wheel bearing assemblies shifts some of that liability away from the shop and mechanic.

Be aware too that very often broken wheel studs are caused by not using a click-type torque wrench when tightening the nuts. With regular hand tools, it is rather easy to over-tighten the nuts. That can stretch the stud, peel the threads, and grind into the formed seating surface on the wheel. Peeled threads usually cause the nut to seize on the stud. Later, it will spin but not back off. It has to be cut off, usually damaging the wheel. The person who over-tightened it last time, often a year or two earlier, is at fault, but it's the current mechanic trying to remove the nut who unfairly gets the blame for that damage. If you think of it logically, you don't cause stress damage by loosening the nut.

For decades, Chrysler called for 95 foot / pounds for their lug nuts on front-wheel-drive vehicles with steel wheels, and 85 foot / pounds with cast aluminum wheels. For your model year they're listing 100 foot / pounds. Nothing is listed for type of wheel material.

Also, for the benefit of others researching this topic, if lug nuts are not tightened to the specified tightness, the wheel can work loose. You will typically hear a clicking twice per wheel revolution, then a subtle shaking, and a wobbling sound, as it becomes more loose. If ignored long enough, the wheel can fall off, but most people resolve the problem long before that happens. Once the wheel has been driven on loose, the tapered surfaces of the holes have been damaged and the wheel and all of the nuts must be replaced. The mating surfaces are shaped so the friction between them is what holds the nuts tight. Those nuts can be retightened to drive the vehicle to a shop, but they definitely will come loose again. There's no saving the wheel or the nuts once those friction surfaces have been degraded.

If your mechanic is willing to replace just the two wheel studs, it is very common to be asked to return a day or two later so they can recheck the lug nut tightness. Someone will run out to your vehicle in the parking lot while you wait. They do that just in case the new stud didn't get pulled in quite all the way. Cornering forces on the wheel will finish the job, but that can leave the nut not quite up to the 100 foot / pounds desired. This double-check takes less than a minute, but it shows their desire to keep your vehicle safe.

Image (Click to make bigger)

SPONSORED LINKS

Wednesday, April 17th, 2024 AT 3:17 PM