Your car has a float type sender unit inside the gas tank. The wacky gauge could be caused by the arm or the resistance card on it being worn. However it's also possible that the motor that moves the gauge could be the culprit. A test to see which it is would be to connect a scan tool that can read live data, specifically the fuel level. Then see if that value floats around like the gauge does. If it does it is the sender, however if the scan tool says you have a half tank and is steady but the gauge is bouncing around it is likely the motor in the cluster. The sender unit is attached to the in tank pump assembly. It requires the fuel tank be drained or run as low as possible. Then you remove the pump assembly and replace the sender. However the level sender itself is close to 120.00 for the OEM unit, you can buy a complete OEM pump from a place like rock auto for 190.00 If the pump hasn't been replaced that might be a better option as you would already be removing it. You would also be getting the updated pump design and a new connector.

If you are in an area that rusts you might want to order the replacement fuel tank lock ring as well, they can rust and get flimsy and make it hard to get things to seal.

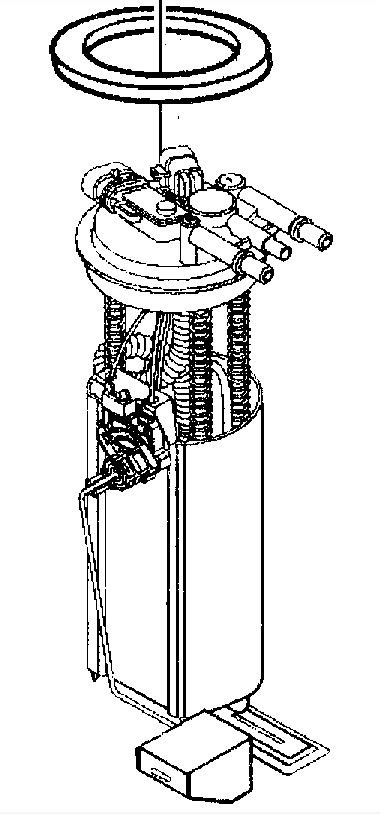

Fortunately GM put an access panel under the carpet in the trunk area. Peel the carpet back from the seat area, under it you will find the cover. Remove the screws in it, then gently pry it up, it has a sealant under it so try not to bend it too bad. With it out of the way you can use an air nozzle or similar to clean all the crud off the top of the tank. You don't want it in the tank!

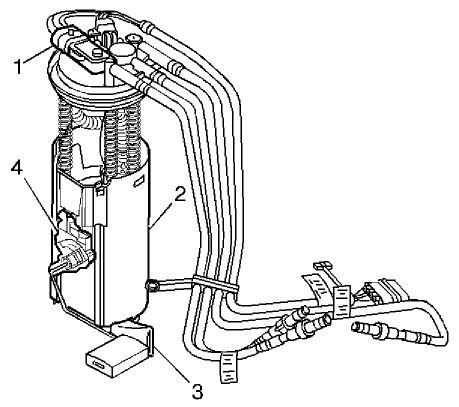

Next you will see the lines and connectors like the third picture. You unplug the electric connectors first. Now the important step, start the engine and let it run until it shuts off, then turn off the key. This step should remove any fuel pressure from the lines so you don't get a shower of gas. I'd still put a rag over the lines and wear gloves, gas stinks! The lines are held on with quick connects they squeeze to release them. I like to mark them just to be sure they go back on correctly, Be gentle, they can break.

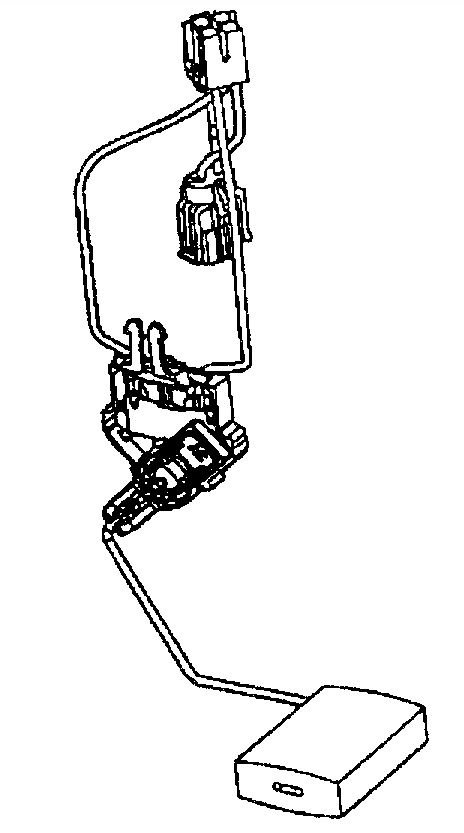

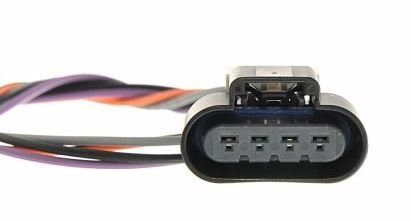

Now that you have the electrical and fuel lines out of the way you can use a brass punch or the proper ring tool to rotate the ring and release it. Remove the ring and lift the pump up, after blowing any leftover dirt out of the way. Catch the seal ring under it. It shouldn't fall through the hole but why tempt fate. Now toss the old pump into a metal pail or dish. Just to keep it from leaking the fuel in the baffles out into the trunk. Now that the pump is out you can see the level sender. If you are replacing only it, you release the tabs and the wire connections and swap in the new one. If not take the new pump and install the gasket around it like the old one had it. Now for the hard part. You need to push down on the pump to compress the seal while you set the retainer ring into place and lock it in. Now reconnect the fuel lines, and the tank pressure sender. If you have the old style 2X2 connector, chances are the new one has a single row of four. They usually include the instructions for swapping them over. Plug it in and test it by turning the key on and off, wait about 30 seconds and cycle it again, you are building the fuel pressure back up. Now check the lines for any leaks. If none, start the engine and check again. If no leaks, re-install the access cover and put the carpet back. Enjoy.

Images (Click to make bigger)

Friday, January 31st, 2020 AT 4:46 PM