Hi bestscorpion

DTC P0441: INCORRECT EVAP PURGE FLOW OR DTC P0446: EVAP VENT CONTROL FAULT

CAUTION: If ECM replacement is instructed in following testing, always ensure ECM connectors and ground circuit are okay. If either are suspect, repair and repeat testing to confirm ECM malfunction.

NOTE: If DTC P0441, P0446, P0450 or P0451 is output after DTC P0440, perform appropriate test first before performing DTC P0440 test.

Circuit Description

Vapor pressure sensor and Vacuum Switching Valve (VSV) for vapor pressure sensor are used to detect faults in EVAP system.

DTC is set if EVAP system leak is detected or if there is a malfunction in EVAP VSV, vapor pressure sensor VSV or in vapor pressure sensor. Possible causes are: � � �

Open or short in VSV circuit for vapor pressure sensor. � � �

Open or short circuit in vapor pressure sensor circuit.

VSV for vapor pressure sensor. � � �

Vapor pressure sensor. � � �

VSV for EVAP. � � �

Open or short in VSV circuit for EVAP. � � �

Disconnected or blocked vacuum hose. � � �

Charcoal canister.

Diagnosis & Repair (Using OBD-II Scan Tool

1. Check EVAP VSV, vapor pressure sensor VSV and vapor pressure sensor wiring harness connectors for damaged pins, corrosion and loose wires. Vapor pressure sensor and vapor pressure sensor VSV is located on charcoal canister under rear of vehicle, near fuel tank. EVAP VSV is located near air filter housing. Repair connectors as necessary. If connectors are okay, go to next step.

2. Check all EVAP related vacuum hoses for cracks, looseness and correct routing. For proper vacuum hose routing, see appropriate illustration in VACUUM DIAGRAMS article. Repair vacuum hoses as necessary. If vacuum hoses are okay, go to next step.

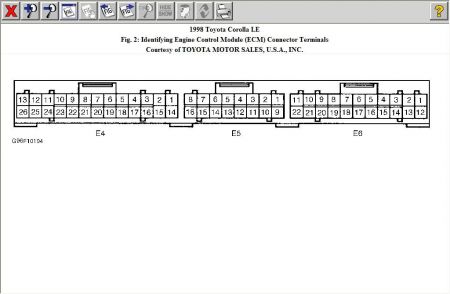

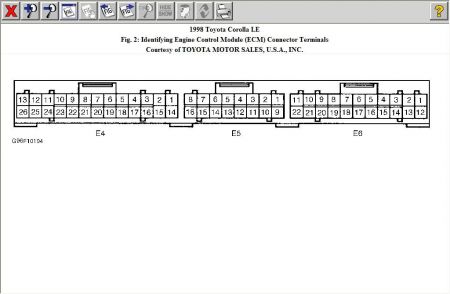

3. Access ECM behind glove box. Turn ignition on. Backprobing ECM connector, measure voltage between terminals No. 1 (Yellow wire) and No. 9 (Brown wire) at ECM E5 connector. See Fig. 2 . If voltage is 4.5-5.5 volts, go to next step. If voltage is not 4.5-5.5 volts, replace ECM.

4. Backprobing ECM connector, measure voltage between terminals No. 7 (Blue wire) and No. 9 (Brown wire) at ECM E5 connector. Disconnect vacuum hose from vapor pressure sensor. Sensor is located on top of charcoal canister under rear of vehicle, near fuel tank. Connect a vacuum pump to sensor. If voltage is 3.0-3.6 volts without vacuum applied and 1.3-2.1 volts with .59 in. Hg (2 kPa) applied, go to step 6). If voltage is not as specified, go to next step.

5. Check for an open or short in wiring harness between vapor pressure sensor and ECM. See appropriate wiring diagram in WIRING DIAGRAMS article. Repair wiring as necessary. If wiring is okay, replace vapor pressure sensor.

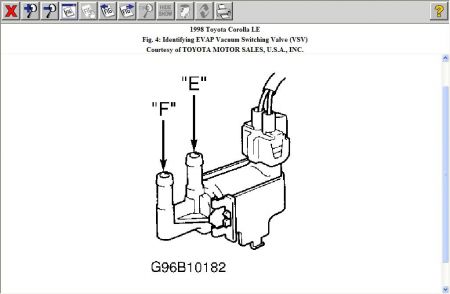

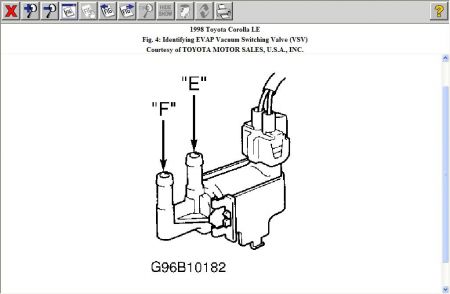

6. Disconnect EVAP VSV vacuum hoses. EVAP VSV is located near air filter housing. Apply air pressure to VSV port "E". See Fig. 4 . Air should not flow from port "F". Access ECM behind stereo on instrument panel, just in front of center console. Turn ignition on. Connect a jumper wire between ground and terminal No. 8 (Blue/Black wire) at ECM E4 connector. See Fig. 2 . Air should flow from port "F". If VSV functions as specified, go to step 9). If VSV does not function as specified, go to next step.

7. Check vacuum hose between intake manifold and EVAP VSV, and hose between EVAP VSV and charcoal canister. Replace vacuum hoses as necessary. If vacuum hoses are okay, check EVAP VSV. See EMISSION SYSTEMS & SUB-SYSTEMS in appropriate SYSTEM/COMPONENT TESTS article. Replace VSV as necessary. If VSV is okay, go to next step.

8. Check for an open or short in wiring harness between EFI main relay, EVAP VSV and ECM. See appropriate wiring diagram in WIRING DIAGRAMS article. Repair wiring as necessary. If wiring is okay, replace ECM.

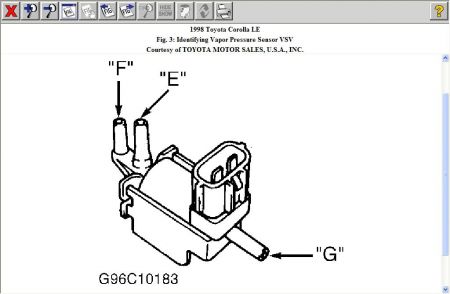

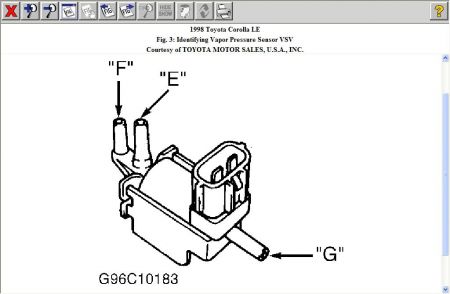

9. Disconnect vapor pressure sensor VSV vacuum hoses. VSV is located on charcoal canister under rear of vehicle, near fuel tank. Apply air pressure to VSV port "E". See Fig. 3 . Air should flow from port "G". Access ECM behind stereo on instrument panel, just in front of center console. Turn ignition on. Connect a jumper wire between ground and terminal No. 7 (Red wire) at ECM E4 connector. See Fig. 2 . Air should flow from port "F". If VSV does not function as specified, go to next step. If VSV functions as specified, go to step 12).

10. Check vapor pressure sensor VSV. See EMISSION SYSTEMS & SUB-SYSTEMS in appropriate SYSTEM/COMPONENT TESTS article. Replace VSV as necessary. If VSV is okay, go to next step.

11. Check for open or short circuit in wiring harness between EFI main relay, vapor pressure sensor VSV and ECM. See appropriate wiring diagram in WIRING DIAGRAMS article. Repair wiring harness as necessary. If wiring harness is okay, replace ECM.

12. Check fuel tank and overfill check valve. See ON-BOARD REFILLING VAPOR RECOVERY (ORVR) SYSTEM under EMISSION SYSTEMS & SUB-SYSTEMS in appropriate SYSTEM/COMPONENT TESTS article. Replace check valve as necessary. If check valve is okay, check charcoal canister. See EMISSION SYSTEMS & SUB-SYSTEMS in appropriate SYSTEM/COMPONENT TESTS article. Replace charcoal canister as necessary.

© 2007 Mitchell Repair Information Co.,

Sunday, September 28th, 2008 AT 4:45 AM