Here is the removal and install

REMOVAL & INSTALLATION

4A-F, 4A-FE and 4A-GE Engines

Disconnect the negative battery cable.

Raise and safely support the vehicle.

Drain the engine oil in a suitable container

Place a jack under the transaxle to support it.

Remove the splash shield from under the engine.

Raise the jack under the transaxle slightly.

Remove the front pipe from the exhaust manifold and catalyst. Some models have a oxygen sensor, disconnect the wiring.

On the 4A-F and 4A-FE engines, remove the center mounting.

Some 4A-FE engines and all 4A-GE engines are equipped with a stiffener plate. Remove the set bolts and pull the stiffener plate from the vehicle.

On the 4A-GE engines, unbolt and lower the flywheel housing under cover.

If equipped, remove the oil cooler hose and union from the oil pan. Remove the two nuts and nineteen bolts retaining the oil pan.

Insert a blade between the pan and cylinder block, cut off the applied sealer and remove the pan.

To install:

Be careful not to drop any oil on the contact surfaces of the pan and block.

Using a razor blade and gasket scraper, remove all traces of packing (FIPG) material from the gasket surfaces. Thoroughly clean all main surfaces to remove loose material. Clean both sealing surfaces with non-residue solvent.

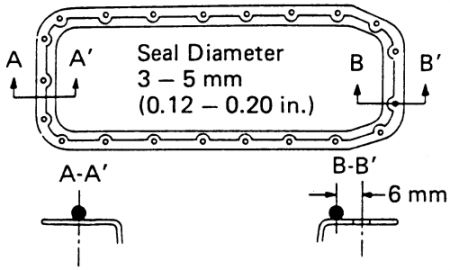

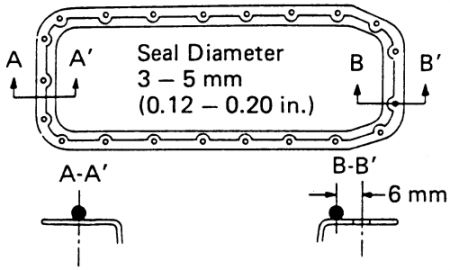

Apply new packing (FIPG) 08826-00080 to the oil pan as shown. Avoid apply excessive amounts to the surface. Be especially careful around the oil passages.

Parts must be assembled within 3 mins of application. Otherwise, the sealer (FIPG) must be removed and reapplied.

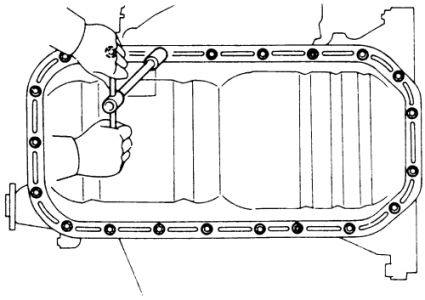

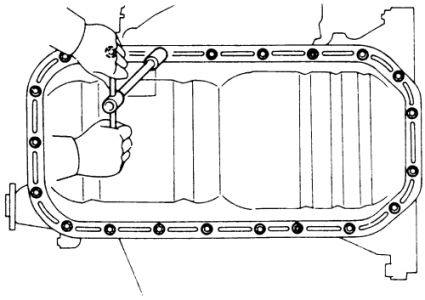

Install the oil pan over the studs on the block with the nineteen bolts and two nuts. Tighten the bolts to 43 inch lbs. (5 Nm). Make sure when you install the oil pan drain plug, you use a new gasket.

If equipped, install the oil cooler pipe, two new gaskets and union bolt. Tighten the union bolt to 18 ft. lbs. (25 Nm).

Install the front exhaust pipe (with new gaskets on either end of the pipe) to the manifold.

On the 4A-GE engines, install and secure the flywheel housing under cover if removed.

On the 4A-FE engines if removed, attach the stiffener plate. tighten the No. 1 bolt first then the 5 bolts in the sequence shown. Tighten to 17 ft. lbs. (23 Nm).

On the 4A-GE engines, attach the stiffener plate with the 3 set bolts and tighten them to 27 ft. lbs. (37 Nm).

Attach the center mounting and tighten the member side bolts to 38 ft. lbs. (52 Nm), plate side to 17 ft. lbs. (23 Nm).

Lower the jack from the transaxle.

Lower the vehicle, and fill the crankcase with the appropriate amount of engine oil. Refer to the Capacities chart.

Connect the negative battery cable, start the engine and check for leaks. If all is well, raise the vehicle slightly and install the engine under cover.

Recheck the engine oil level, top off if necessary.

Monday, January 26th, 2009 AT 7:39 PM