You still haven't posted the voltage readings I need. For the "4" and "5" you listed, are those engine speed as in 400 rpm, or 4.0 volts for the throttle position sensor reading?

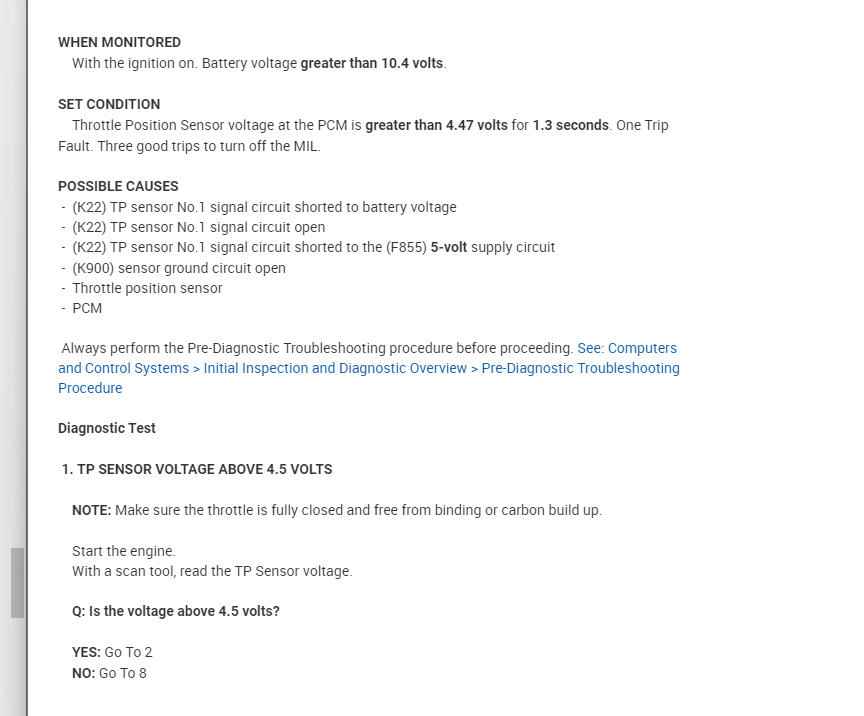

Your mechanic would have used a scanner, so we know we have access to the information we need. All of the voltage tests I listed can be boiled down to just one thing on the scanner. That's the "TPS Signal Voltage". It must vary between roughly 0.5 to 4.5 volts from idle to wide-open-throttle. If that is what's seen on the scanner, that is what the computer is seeing, and that range can only occur if every other part of the circuit is working. At that point no other tests are needed or will provide any useful information.

The fault code(s) should be erased, then observe if and when it sets again. If it sets again immediately, there is a defect that is occurring right now and should show up as a wrong TPS signal voltage on the scanner. If the code comes back later, typically during a test-drive, we're looking for an intermittent problem. This is where spread or corroded connector terminals become the best suspect. Wiggling wiring harnesses might make the defect show up. Watching the reading during the test-drive can also help by showing what it takes to make the defect occur.

I'm surprised that I failed to make two comments earlier. I apologize for that. Thought I would have done that before. The first is I have to correct the ground voltage I listed as ".02 volts". In fact, I was corrected earlier and overlooked it. You will see 0.2 volts, (two tenths of a volt). In this circuit that is significantly different than 0.00 volts as would be expected, on a ground wire, or.02 volts.

The second has to do with "minimum throttle". This has to do with idle speed that's too low, and to my knowledge, it only applies to Chrysler products. Any time the battery is disconnected or run dead, and fifty percent of the time when you replace the throttle position sensor, minimum throttle has to be relearned. Fuel trim data and all other sensor personalities are relearned right away without you even noticing. Minimum throttle is the one big exception. That requires a very specific set of conditions so the computer knows your foot is off the accelerator pedal.

To meet those conditions, drive at highway speed with the engine warmed up, then coast for at least seven seconds without touching the pedals.

Until that is done, idle speed will be too low. The engine may not start unless the accelerator pedal is held down 1/4". It will not give the nice "idle flare-up" to 1500 rpm at start-up, and it will tend to stall at stop signs.

Remember I mentioned the proper range for the TPS signal voltage is 0.5 to 4.5 volts, but that is for training purposes. In actual practice those values are approximate and will be different for every sensor. When minimum throttle is learned, the computer puts into memory the signal voltage it sees from the TPS at that instant. From then on, any time it sees that same voltage, it knows it has to be in control of idle speed. If anything happens after that to make that voltage lower, it immediately puts that new value into memory instead. That's what happens half the time when you install a new throttle position sensor. However, if you install one with a slightly higher voltage at idle, the computer will think you're holding the accelerator pedal down, so it leaves idle speed up to you. Eventually you're going to be driving and you'll meet the conditions for minimum throttle to be learned again for the new sensor, then any symptoms will "magically" disappear.

With the scanner, your mechanic had the perfect opportunity to see why engine speed was too low. That goes back to the idle "steps" I started to describe. I got as far as saying step "32" was a typical value you could find, out of the 256 total steps for a properly-running engine. If the engine is cold, it will be a little higher. Same if there's a higher load on the engine, such as when running the AC compressor or when shifting into gear. If anything slows the engine down, the computer will raise the idle speed motor / valve to a higher step in an attempt to get idle speed back up to where it should be.

There's three things we can learn from looking at the idle step number on the scanner. The scanner will also list the actual idle speed and the "desired idle speed". If those two are the same, the computer has achieved the results it is after. When they're different, the step number tells us what type of problem to look for. For example, if idle speed is too high, the step number will be lower than normal, say step 15. That shows the computer is trying to lower idle speed, but without success. A vacuum leak is the common suspect. If the idle step number is higher than normal but actual idle speed is too low, the computer wants idle speed to be higher but can't get it there. Similarly, if idle speed appears to be okay, but the step number is unusually high, the computer has achieved the idle speed it wants but it's overcoming something to do that. A common cause is a spark-related misfire. One misfiring cylinder will lower engine speed, then increasing the step number will make the other cylinders work harder to get idle speed back up to where it should be. For a single-cylinder misfire, step "50" is about what you'd expect to see.

The most overlooked clue is when the idle step number is listed as "0". That only occurs when minimum throttle hasn't been relearned. Then, a test-drive is in order to perform that relearn before wasting time trying to find other causes of low idle speed, (that don't exist). Step "0" proves the computer is not trying to control idle speed, so you can expect speed to be too low.

SPONSORED LINKS

Thursday, February 3rd, 2022 AT 1:19 PM