This is what my book have on it hope it help

good luck

EVAPORATOR

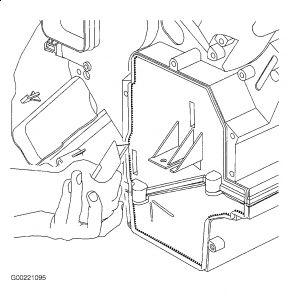

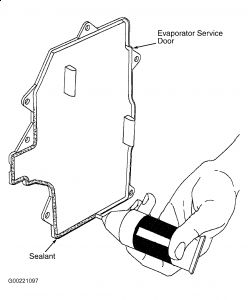

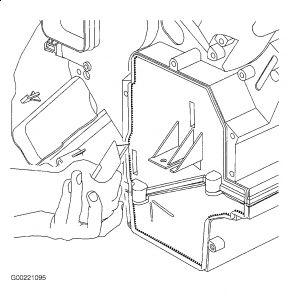

CAUTION:When cutting open evaporator access door, avoid cutting internal components. Cut only inside raised bead area. Do not cut through or damage raised bead, this bead will be used as a sealing surface when completing the procedure.

CAUTION:Cap or tape open A/C hoses and A/C refrigerant components immediately to prevent A/C system contamination. Use only Polyalkylene Glycol Synthetic Refrigerant Oil (PAG) for internal circulation through the R-134a A/C system and only 525 viscosity mineral oil on fitting threads and "O" rings. If lubricants other than those specified are used, compressor failure and/or fitting seizure may result.

Removal

Turn ignition ON and select outside air on control head. Disconnect negative battery cable. Recover refrigerant. See RECOVERY, EVACUATION & RECHARGING in GENERAL SERVICING PROCEDURES article in GENERAL SERVICING. Measure amount of oil removed during recovery process.

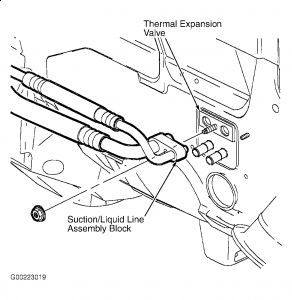

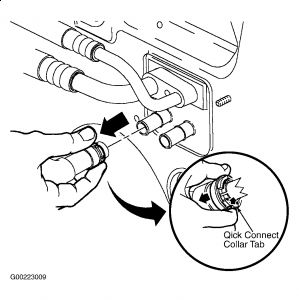

Remove Thermal Expansion Valve (TXV.

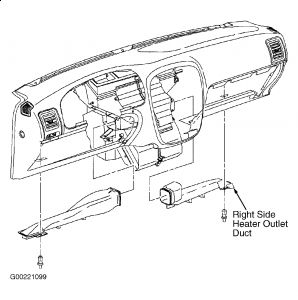

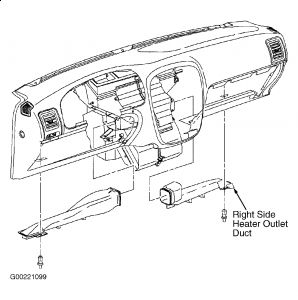

Disconnect negative battery cable. Open glove compartment door and remove glove compartment lamp assembly by pulling on lamp plunger. Disconnect glove compartment lamp wiring harness from glove compartment lamp. Remove right side Instrument Panel (I/P) lower dash insulator retainers. Pull insulator rearward to detach the insulator from forward insulator retainers. Remove right side heater outlet assembly retainer and remove outlet.

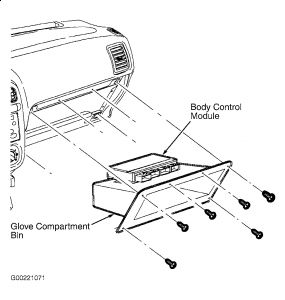

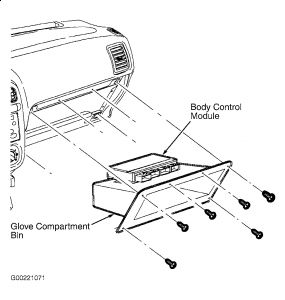

Remove glove compartment door. Remove glove compartment bin fasteners and slowly remove glove compartment bin tilting bin downward to expose the Body Control Module (BCM) residing on top of glove compartment. Remove the BCM from glove compartment by sliding module out of attaching slots. Remove glove compartment bin..

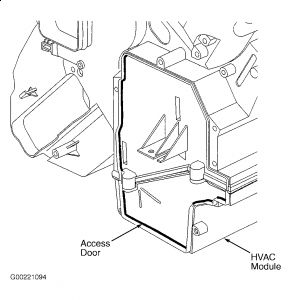

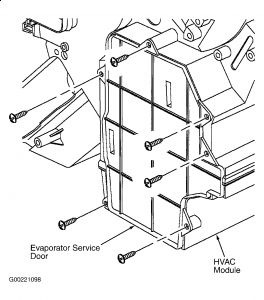

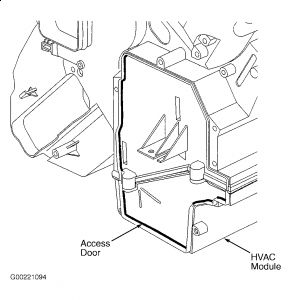

Locate evaporator access door location on right side of the module. Entire area inside raised lip is to be cut out.

Using a sharp utility knife, cut through module wall, following inside of raised bead as a guide. Several passes may be necessary to accomplish this..

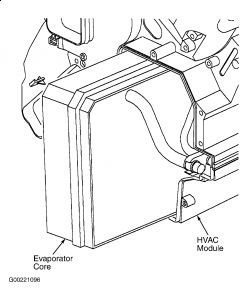

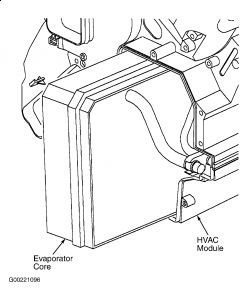

From inside of vehicle, slide evaporator core out through access door opening. Use care not to damage core fins or pipes.

Carefully clean out any debris that may be inside of module.

Installation

Add amount of compressor oil that was removed during discharge to evaporator core. If a NEW evaporator core is being installed, add appropriate amount of compressor oil to system for evaporator core being replaced. See SPECIFICATIONS .

Carefully install evaporator into module, making sure not to bend pipes or damage foam seals.

Inspect module/TXV foam seal to verify proper location. Install TXV.

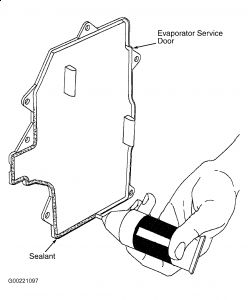

NOTE:Proper sealing is important to prevent condensation from leaking into the passenger compartment.

Apply sealant provided in service kit around perimeter of evaporator core service door tongue and groove location.

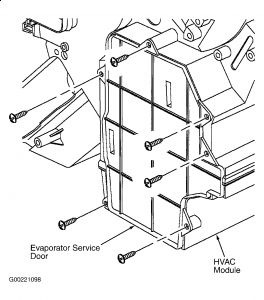

Install evaporator core service door to module and install screws.

Tighten to specification

Install glove compartment bin partially into opening and secure BCM module to glove compartment bin slots.

Route glove compartment lamp wiring harness through lamp opening and install glove compartment bin to I/P. Install and tighten glove compartment screws to specification. Connect glove compartment lamp wiring harness to glove compartment lamp and snap lamp into glove compartment bin.

Install right side heater outlet duct with retainer. Install lower dash insulator with retainers.

Install glove compartment door and fasteners. Tighten glove compartment door fasteners to specification. Connect negative battery cable and check for proper alignment of glove compartment door and function of glove compartment lamp.

Evacuate and recharge A/C system

. Ensure A/C system is operating properly.

Turn HVAC blower on with mode set to HEATER, temperature on HOT, recirculation on OUTSIDE AIR. Use the back of your hand to check for any air leaks around service door. If any leaks are detected, door must be removed and resealed.

Friday, October 23rd, 2009 AT 1:11 PM