Welcome to 2CarPros.

When I have a vehicle that the transmission works and then doesn't, one of the first things I question are the basics as you have. Next, I question if there is a pressure related issue (transmission line pressure), How many miles have been put on this vehicle since the rebuild? Was the torque converter or front pump replaced?

Please keep in mind, although it was rebuilt, often times people do a soft part overhaul. Basically they replace clutches, bushings, shims and so on. The valve body may or may not have ever been taken apart. So something could be causing a bind there.

Next, I have also see conditions that the linkage was not adjusted properly and the transmission, although it appears to be in the selected gear, is not fully engaged in the gear. When this happens, move the shifter slightly in both directions to see if it engages.

The last thing I would check is line pressure. If line pressure is low, it will struggle to shift into gear. Here are directions for testing line pressure. The attached 2 pics correlate with the directions.

______________________________________________

2008 Ford Truck Escape 2WD V6-3.0L

Line Pressure Test

Vehicle Transmission and Drivetrain Automatic Transmission/Transaxle Testing and Inspection Component Tests and General Diagnostics CD4E Automatic Transmission Line Pressure Test

LINE PRESSURE TEST

Line Pressure Test

CAUTION: Carry out Line Pressure Test before carrying out Stall Speed Test. If line pressure is low at stall, do not carry out stall test or further transaxle damage may occur. Do not maintain wide open throttle (WOT) in any gear range for more than 5 seconds. See: Automatic Transmission/Transaxle > Component Tests and General Diagnostics > Stall Speed Test

CAUTION: The transaxle vehicle harness must be connected to verify these pressures.

The Line Pressure Test verifies that the line pressure is within specifications.

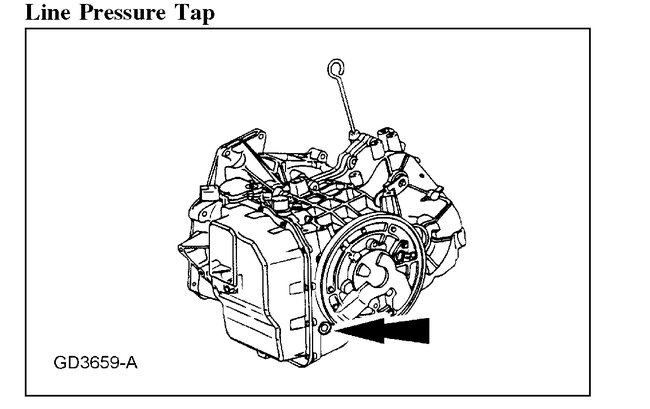

1. Remove the line pressure port plug.

2. Connect pressure gauge to line pressure tap.

Line Pressure Tap

pic 1

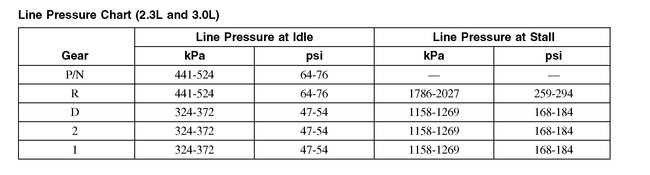

3. Start engine and check line pressures. Refer to following the Line Pressure Chart to determine if line pressure is within specifications.

4. If line pressure is not within specifications, carry out on-board diagnostics and pinpoint test, air pressure check and repair main control system or pump as required.

5. After completing the line pressure test install the line pressure port plug.

Tighten to 14 Nm (10 lb-ft).

Line Pressure Chart (2.3L and 3.0L)

pic 2

___________________________

Let me know if any of this helps. Also, if you could, let me know if the torque converter was replaced or anything you can find out about the overhaul.

Take care,

Joe

Images (Click to make bigger)

SPONSORED LINKS

Monday, October 14th, 2019 AT 6:49 PM