Ok now test the CTS(coolant temp) sensor. Also this tech bulliten may appy to yours. INTAKE VALVE DEPOSITS - STALLS/ROUGH IDLE/NO POWER TECHNICAL SERVICE BULLETIN Reference Number(s): 18-20-94, Â Date of Issue: Â October 21, 1994 Related Ref Number(s): 18-20-94 ARTICLE BEGINNING INTAKE VALVE DEPOSITS Model(s): 1994 Dodge (AG) Daytona, (AP) Shadow, Shadow Convertible 1994 Plymouth (AP) Sundance 1994-95 Chrysler (AA) LeBaron, (AJ) LeBaron Coupe, LeBaron Convertible, (AS) Town & Country 1994-95 Dodge (AA) Spirit, (AS) Caravan 1994-95 Plymouth (AA) Acclaim, (AS) Voyager Group: Vehicle Performance Bulletin No.: 18-20-94 Date: October 21, 1994 SYMPTOM/CONDITION Driveway die out, rough idle, lack of power, sags, and hesitation. DISCUSSION The listed symptoms and conditions may be the result of build up of deposits on the back of the intake valves causing blockage of the fuel delivery into the engine upper combustion chamber. This blockage consequently results in fuel starvation. The deposits are the result of fuel blending methods and generally have insufficient or ineffective fuel detergent additives. Fuel quality is a direct result of the base crude stock used, the process used to refine the crude oil, the storage system, delivery and distribution methods, and the careful blending of the additive packages and the oxygenate compounds. Using fuel with a higher minimum posted octane number does not guarantee that fuel is high quality or that the fuel is blended with adequate or effective detergent, corrosion and stability additives. Gasoline/Oxygenate blends which use unleaded gasoline and materials that contain oxygen, such as alcohol (ethanol), MTBE and ETBE, also are not an indication that adequate or effective detergent additives are available in the final product. Gasoline Companies are acknowledging that fuel quality is important. A number of them are advertising, as well as "warrant" that their product is blended to contain the necessary additives for efficient and clean operation of motor vehicles. Fuels available from these companies should be considered to assure full performance and clean operation. Page 1 of 2 INTAKE VALVE DEPOSITS - STALLS/ROUGH IDLE/NO POWER -1995 Plymouth ...DIAGNOSIS For vehicles exhibiting any one or more of these symptoms, there are several possible procedures that can be followed. First and foremost make sure that all vehicle systems are operating as designed. 1. Using the Scan Tool (DRB III) and appropriate Diagnostic Procedures or the Mopar Diagnostic System, verify that all vehicle engine systems are functioning as designed. If Trouble Codes (Diagnostic Trouble Codes) are present, record them on the repair order for future reference and repair as necessary. If all engine systems are functioning as designed, ask the customer about the fuel that is being used in the vehicle. If there is a question about the quality of the fuel, suggest that only fuels be used that are "warranted" by the gasoline company against the build up of deposits. 1. REPAIR PROCEDURE Depending on the amount of deposit on the valves there are several methods that can be used to remove them. The use of Mopar Fuel Injector Cleaner has shown reasonable results on light deposits. Add one bottle of Mopar Fuel Injector Cleaner, P/N 4318007, to a full tank of gas. 1. CAUTION: Under no circumstances should this fuel injector cleaner be added to a partially filled fuel tank. Mopar fuel injector cleaner will remove light deposits that have built up over a period of time. However, it is not intended for continuous use. Owners should be advised of the cause of their driveability problem and a recommendation should be made to try other brands of gasoline. For moderate to heavy deposits, the intake valves should be cleaned. The suggested method for cleaning the intake valves involves the removal of the cylinder head from the engine. The cylinder head must be disassembled, and the carbon removed from the valves with a wire brush. 1. WARRANTY INFORMATION POLICY: Information Only

Test CTS and IAT intake air temp sensors like this:

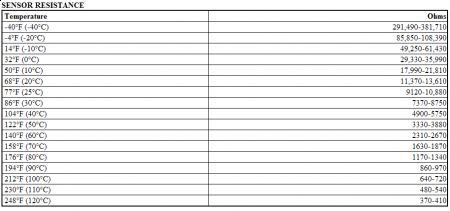

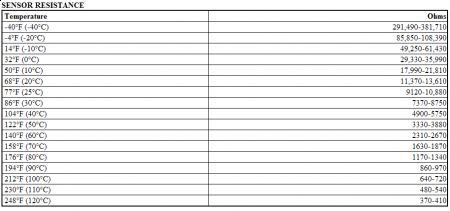

INTAKE MANIFOLD AIR TEMPERATURE SENSOR 1. Intake manifold air temperature sensor is mounted in intake manifold extending into air stream. 2. Turn ignition off, disconnect intake manifold air temperature connector. Using DVOM, measure resistance between sensor terminals. See SENSOR RESISTANCE table. If resistance is not within specification, replace intake manifold air temperature sensor. COOLANT TEMPERATURE SENSOR (CTS) 1. Sensor is mounted in intake manifold, next to thermostat housing. 2. With key off, disconnect wire connector from sensor. Connect ohmmeter between sensor terminals. See SENSOR RESISTANCE table. If ohmmeter readings are not within specification, replace CTS.

Saturday, November 28th, 2009 AT 8:58 AM