Again you never asked about FPR/Rollover valve? They are not integrated into the TBI they are located on the fuel tank? The FPR only releases pressure from the tank the rollover valve is there in case of vehicle rollover? To release pressure from throttle body

Throttle Body Injection (TBI)

Slowly open fuel tank cap to release pressure in tank. Disconnect 2-pin injector connector at edge of throttle body. Connect a jumper wire between injector connector (injector side) Dark Green/Orange wire and battery positive terminal.

Connect another jumper wire to injector connector (injector side) White/Dark Blue wire. Momentarily ground jumper wire connected to White/Dark Blue wire no more than 5 seconds. Injector will energize open, relieving fuel pressure. Remove jumper wires. Fuel pressure is now released.

FUEL PUMP & FUEL PRESSURE REGULATOR TEST

WARNING:Perform fuel pump test with fuel tank at least half full. Before disconnecting fuel line, relieve fuel pressure.

2.2L TBI, 2.2L Turbo, 2.5L TBI & 3.0L

Relieve fuel pressure. See RELIEVING FUEL PRESSURE under FUEL PRESSURE. On 3.0L, disconnect vacuum hose from fuel pressure regulator before checking fuel pressure.

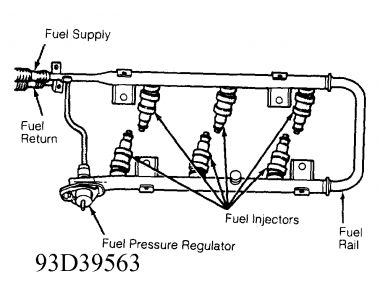

On 2.2L TBI and 2.5L TBI, fuel pressure regulator is not vacuum assisted. On all engines, disconnect fuel supply hose quick-disconnect connector from chassis lines at engine. Connect Fuel Pressure Gauge (C-4799) to Fuel Pressure Test Adapter (6539). Install adapter between fuel supply hose and chassis fuel line.

CAUTION:DO NOT activate fuel pump for long periods, or engine may hydrostatically (liquid) lock.

Using Diagnostic Readout Box (DRB-II), turn ignition switch to ON position. Select ASD FUEL SYSTEM TEST mode. In this mode, DRB-II energizes Auto Shutdown (ASD) relay, causing fuel pump to activate and pressurizing fuel system.

Note fuel pressure, and record reading. Relieve fuel pressure. Remove fuel pressure gauge. If fuel pressure is within specification, fuel system is functioning properly and further testing is not required. See FUEL SYSTEM PRESSURE SPECIFICATIONS table.

If fuel pressure is greater than specification, go to step 8. If fuel pressure is less than specification, install Fuel Pressure Gauge(C-4799) and Fuel Pressure Test Adapter (6539) in fuel supply line between fuel tank and fuel filter.

Repeat ASD FUEL SYSTEM TEST. If fuel pressure is at least 5 psi greater than fuel pressure recorded in step 4, replace fuel filter. If no change is observed, gently squeeze fuel return hose.

If fuel pressure increases while squeezing fuel return hose, replace fuel pressure regulator. If fuel pressure does not change while squeezing fuel return hose, problem may either be a plugged fuel inlet strainer or defective fuel pump. Repair as necessary.

Disconnect fuel return hose from fuel pump at fuel tank. Connect Fuel Pressure Test Adapter (6541) to fuel return hose. Place other end of adapter into an approved 2 gallon gasoline container.

Turn ignition switch to ON position. Repeat ASD FUEL SYSTEM TEST. If pressure is now correct, replace fuel pump assembly. See FUEL SYSTEM PRESSURE SPECIFICATIONS table. If pressure is still greater than specification, deactivate fuel pump. Remove fuel pressure test adapter, and connect fuel pump return hose.

Disconnect fuel return hose from chassis fuel lines at engine. Connect Fuel Pressure Test Connector Adapter (6541) to fuel return hose. Place other end of hose in an approved gasoline container. Repeat ASD FUEL SYSTEM TEST.

If pressure is now correct, check for restricted fuel return line. If no change is observed, replace fuel pressure regulator.

FUEL SYSTEM PRESSURE SPECIFICATIONS

Application(1). Psi (kg/cm2 )

2.2L TBI & 2.5L TBI.39 (2.7)

2.2L Turbo, 2.5L Flexible Fuel & 3.3L (VIN T).55 (3.9)

3.0L, 3.3L (VIN R), 3.5L & 3.8L.48 (3.4)

(1)Specification given is with fuel pressure regulator vacuum hose disconnected.

Tuesday, December 9th, 2008 AT 8:54 PM