Ken,

Thank you, again, for your answer.

As an aside, I rechecked dry and wet compression. Final numbers:

Cyl #1: 101 psi dry; 105 psi wet

Cyl #2: 95 psi dry; 105 psi wet

Cyl #3: 99 psi dry; 103 psi wet

Cyl #4: 96 psi dry; 103 psi wet

Cyl #5: 98 psi dry; 104 psi wet

Cyl #6: 99 psi dry; 112 psi wet

You may be right, that the engine may be worn out, but I don’t think so. The reason is that I have been making progress with it. At first, it was throwing 3 codes consistently, at about 2600 rpm, under load (going uphill and stepping on accelerator. The codes were P0300; P0302 and P0305. After I put in 3 new coils on Bank 1, and plugs all around, it stopped throwing the last two, but was still throwing P0300 under same conditions. I considered that progress, so went back in and installed 6 remanufactured Carquest injectors (and replaced the coil connector on cylinder #4, which had disintegrated). I then went to start it, and it would crank but seemed to have no spark. I figured I had accidentally done something wrong on that last upgrade. About four days later. After a bunch of searching online, and asking former mechanics, etc, to no avail, I finally went to a person I had identified as a mechanic who is very savvy, especially in figuring out specifically WHY things might be happening, and explaining the causes to me in detail. He told me two things:

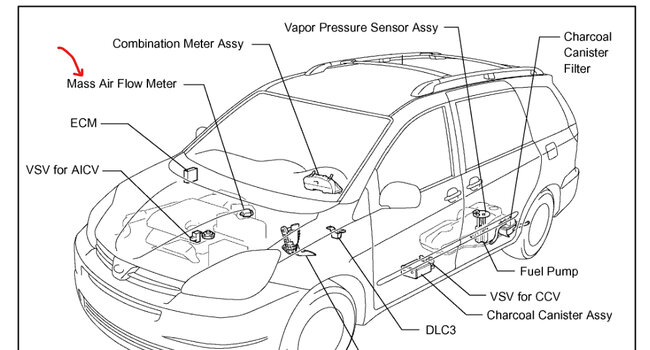

1) He would next install a $29 crankcase position sensor, because the ECM (computer) uses data from that sensor as part of its determining whether or not there are any misfires. Yesterday, I installed the new crankcase position sensor, even though at that point the engine still wouldn’t start. Then I went back to that very smart mechanic and asked him what he would suggest, as I had determined I had no spark (after I grounded coil and plug on #4 to the front Cat shield, cranked it while iPhone was set on RECORD, watching that grounded #4 plug and coil just sit there, emitting no spark whatsoever). I asked him where the electricity would come from to create the spark on #4 coil and plug. He checked out the coil circuitry online and showed me the functions of each of the 4 wires going to coil. I then asked him to look back further to see if there was any fuse or fusible link before the actual coil. Shazam! The diagram showed a 15-amp fuse in that circuit, and that the fuse was under the dash. I went back home and checked that "ign" fuse (I think it was # 48). It was blown! I replaced it and the Van started right up. I then took it on my "standard" test-drive route, where it had thrown the three codes previously, on cue, at 2600 rpm, and most recently had thrown just the P0300 code. This time, I made it almost all the way through my test drive before, as I pushed it hard uphill, at 70 mph and about 3000 rpm, it threw the dreaded P0300 again. But it now threw it at a more stressed stage of operation. So, I consider that as progress in this case, where most mechanics are telling me they have no clue what’s going on, and you are telling me to give up on this engine. But I know it’s running too well, under almost all conditions, for me to give up on it.

I consulted with my go-to thinker, and he gave me suggestion #2

2) Either try switching the three coils I had replaced, but had saved, with the three "original" ones that were now on bank 2. The goal was to see if one, or more, of those original coils, was crapping out under the load conditions I have described. Alternatively, he suggested I pop for three additional, new, Denso coil packs. After considering the options, and at this late stage in this saga, I decided to get the new coil packs.

I will pick them up this morning, install them in bank 2, and make my test run. You may end up being right, and I may need to give up on this engine, but not ready to do so yet!

Sincerely,

Roger

Tuesday, April 4th, 2023 AT 3:59 AM