Thursday, November 21st, 2024 AT 3:56 PM

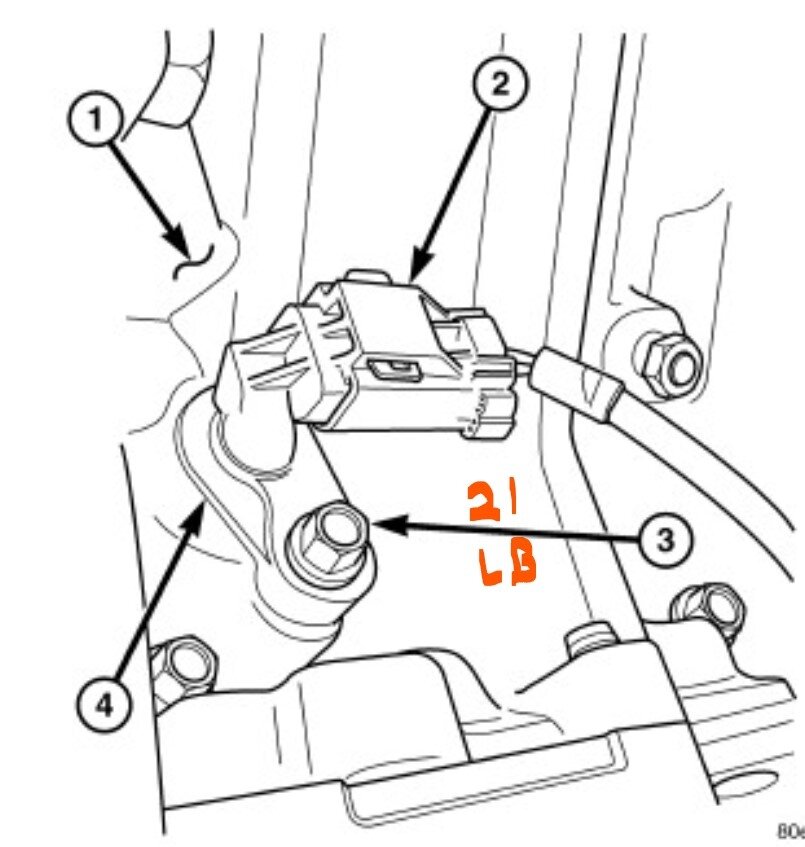

Just purchased this pickup. Got it for cheap because it ran a little rough and would only go into reverse and 1st gear. Throws a P0339 and P0300 code. CMP and CKP sensors have both been replaced. I’ve checked wiring from both sensors to PCM. On both sensors, the reference and signal wires show 4.99v, 0 ohms, continuity from PCM connector to sensor connector on all 3 wires. Neither signal or reference wire is grounded out. Ground wires are also good from sensors to PCM. There is a noticeable slight chirp coming from the rear of engine. The “chirping” is coming from inside the engine. Is it possible I have a bad lifter/valve that could be throwing these codes? I believe my transmission issue is all due to being in limp mode. Check engine light and traction control light are both illuminated as well. I’m sure I’m leaving something out as I’ve been trying to track this problem down for a day and a half now.