I have replaced the following: Plugs, wires, distributor cap and rotor,

Spider injectors, coolant temperature sensor, fuel pump, map sensor, MAF sensor, ignition coil, and probably a few other items along the way.

The fuel pressure is within specs.

I have not yet checked for back pressure from the catalytic converter, although it doesn't run that bad at high speeds.

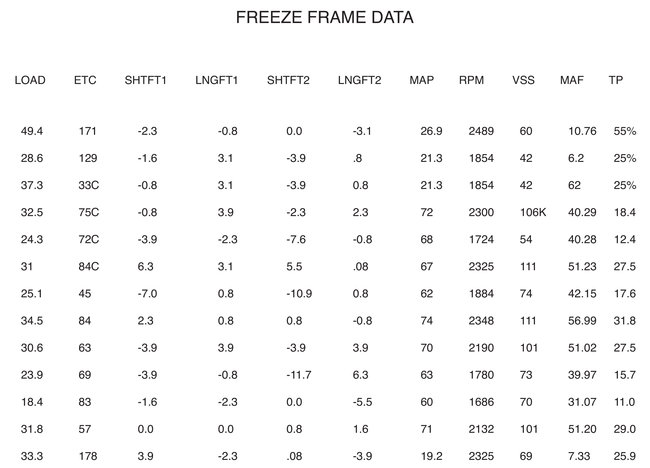

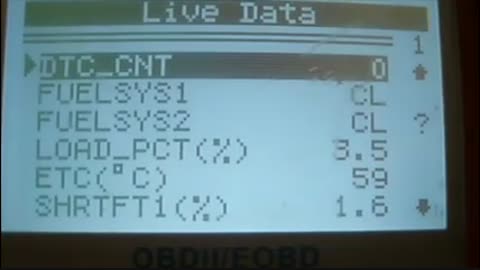

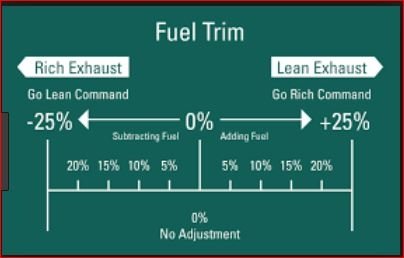

I try to understand the fuel trim data and the o2 sensor stuff, but it is quite confusing to me. I have enclosed several of the freeze frame data I have accumulated, and perhaps you can see causes there. I have also enclosed a video of live data at idle.

I sure hope you can help, because I am running out of things to buy!

SPONSORED LINKS

Monday, April 8th, 2019 AT 7:00 PM