Hi and thanks for using 2CarPros. Com There could be a few things causing this. Here is the outline of possible causes from Alldata:

P0218

P0218-HIGH TEMPERATURE OPERATION ACTIVATED

When Monitored:

Whenever the engine is running.

Set Condition

Immediately when a Overheat shift schedule is activated when the Transmission Oil Temperature reaches 155°C or 240°F.

Possible Causes

ENGINE COOLING SYSTEM OPERATION

TRANSMISSION OIL COOLER PLUGGED

HIGH TEMPERATURE OPERATIONS ACTIVATED

Always perform the 40/41TE Pre-Diagnostic Troubleshooting procedure before proceeding.

Theory of Operation

If the transmission oil temperature rises above 115°C (240°F), the overheat shift schedule is activated as a function of Transmission Oil Temperature and the code is set. The DTC is an informational code only and is being set to aid the technician in determining root cause of a customer driveability issue. The code is also intended to alert the technician to determine if a cooling system malfunction has occurred or if an additional transmission air to oil cooler should be added to the vehicle if the customer regularly drives in a manner that overheats the transmission. Extended operation above 115°C (240°F) will reduce the durability of the transmission and should be avoided. Correcting the cooling system malfunction or installing an additional transmission oil cooler will improve transmission durability especially for customers who operate in city/construction stop and go traffic, tow trailers regularly, drive aggressively in low gear or drive regularly in mountainous areas.

Diagnostic Test

CHECK ENGINE COOLING SYSTEM Perform Engine Cooling System diagnostics.

Is the Engine Cooling System functioning properly?

Yes >> Go To 2

No >> Repair the cause of the engine overheating.

Perform 40/41TE VERIFICATION TEST - VER 1 See: Verification TestsTransmission Verification Test

TRANSMISSION OIL COOLER RESTRICTED Check the Transmission Oil Cooler Flow.

Is the transmission oil cooler restricted or plugged?

Yes >> Repair the cause of the plugged Transmission Oil Cooler as necessary and repair or replace the Transmission Oil Cooler.

Perform 40/41TE VERIFICATION TEST - VER 1 See: Verification TestsTransmission Verification Test

No >> Go To 3

HIGH TEMPERATURE OPERATION This DTC is an informational DTC designed to aid the Technician in diagnosing shift quality complaints.

This DTC indicates that the transmission has been operating in the Overheat shift schedule which may generate a customer complaint.

The customer driving patterns may indicate the need for an additional transmission oil cooler.

With the scan tool, check the DTC EVENT DATA to help identify the conditions in which the DTC was set.

Check for any Service Information Tune-ups or Service Bulletins for any possible causes that may apply.

If there are no possible causes remaining, view repair.

Repair

Repair the cause of transmission overheating.

Perform 40/41TE VERIFICATION TEST - VER 1 See: Verification TestsTransmission Verification Test

___________________________________________

Here is the verification test It will require the use of a scanner:

CONVERSION CALCULATOR

2006 Chrysler Truck PT Cruiser L4-2.4L VIN B

Vehicle � A L L Diagnostic Trouble Codes ( DTC ) � Testing and Inspection � Verification Tests � Transmission Verification Test

TRANSMISSION VERIFICATION TEST

40/41TE TRANSMISSION VERIFICATION TEST - VER 1

NOTE: After completion of the Transmission Verification Test, the Powertrain Verification Test must be performed.

Connect the scan tool to the Data Link Connector (DLC). Reconnect any disconnected components.

With the scan tool, erase all Transmission and Engine DTCs.

NOTE: Erase DTC P0700 under engine to turn off the MIL light off after completion of transmission repairs.

Perform *PRNDL FAULT CLEARING PROCEDURE after completion of repairs for P0706 CHECK SHIFTER SIGNAL.

If the Powertrain Control Module or the Transmission has been repaired or replaced, it is necessary to perform the scan tool Quick Learn Procedure.

If the Torque converter has been replaced, with the scan tool perform TCC BREAK-IN.

If the Powertrain Control Module or Front Control Module has been replaced you must reset the Pinion Factor in the Front Control Module.

With the scan tool, display Transmission Temperature. Start and run the engine until the Transmission Temperature is HOT, above 43°C or 110°F.

Check the transmission fluid and adjust if necessary. Road test the vehicle. With the scan tool, monitor the engine RPM. Make 15 to 20 1-2, 2-3, 3-4 upshifts. Perform these shifts from a standing start to 45 mph with a constant throttle opening of 20 to 25 degrees.

With speeds below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5 seconds each in 2nd and 3rd gear between each kickdown.

For a specific DTC, drive the vehicle to the Symptoms When Monitored/When Set conditions to verify the DTC is repaired.

If equipped with AutoStick(R) upshift and downshift several times using the AutoStick(R) feature during the road test.

NOTE: Use the OBDII task manager to run a Good Trip in each gear, this will confirm the repair and to ensure that the DTC has not re-matured.

Check for any Diagnostic Trouble Codes (DTCs) during and after the road test.

Did any Diagnostic Trouble Codes set during the road test?

Yes >> Refer to Testing and perform the appropriate diagnostic procedure(s).

No >> Repair is complete.

Keep in mind, it could be something as simple as the temperature switch. On this vehicle, the temp switch is integrated with the range sensor. Here are directions for checking and replacing:

TRANSMISSION RANGE SENSOR

DESCRIPTION

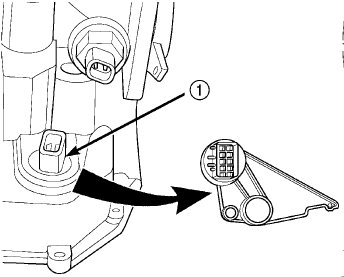

The Transmission Range Sensor (TRS) (1) is mounted to the top of the valve body inside the transaxle and can only be serviced by removing the valve body. The electrical connector extends through the transaxle case.

The Transmission Range Sensor (TRS) has four switch contacts that monitor shift lever position and send the information to the PCM/TCM.

The TRS (1)also has an integrated temperature sensor (thermistor) (2) that communicates transaxle temperature to the TCM and PCM.

OPERATION

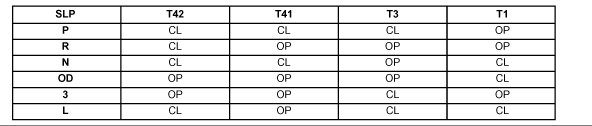

The Transmission Range Sensor (TRS) communicates shift lever position (SLP) to the PCM/TCM as a combination of open and closed switches. Each shift lever position has an assigned combination of switch states (open/closed) that the PCM/TCM receives from four sense circuits. The PCM/TCM interprets this information and determines the appropriate transaxle gear position and shift schedule.

Since there are four switches, there are 16 possible combinations of open and closed switches (codes). Seven of these codes are related to gear position and three are recognized as between gear codes. This results in six codes which should never occur. These are called invalid codes. An invalid code will result in a DTC, and the PCM/TCM will then determine the shift lever position based on pressure switch data. This allows reasonably normal transmission operation with a TRS failure.

TRS SWITCH STATES

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor that the PCM/TCM uses to monitor the transmission's sump temperature. Since fluid temperature can affect transmission shift quality and convertor lock up, the PCM/TCM requires this information to determine which shift schedule to operate in. The PCM/ also monitors this temperature data so it can energize the vehicle cooling fan(s) when a transmission overheat condition exists. If the thermistor circuit fails, the PCM/TCM will revert to calculated oil temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will result in calculated temperature being substituted for actual temperature. Calculated temperature is a predicted fluid temperature which is calculated from a combination of inputs:

Battery (ambient) temperature

Engine coolant temperature

In-gear run time since start-up

See attached pics which correlate with these directions.

_____________________________________________________

I hope this helps. Let me know if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Tuesday, June 5th, 2018 AT 7:03 PM