One thing that I think is going to give more accuracy is if you can use a test light instead of a voltmeter. When you get back to the pump connector, I never paid any attention to the voltage, just whether it was there or not. If there is a high-resistance break in that wire, all it takes is a tiny spot of corrosion or a little carbon track to conduct enough current that the voltmeter will detect the voltage, but obviously that's not enough current to run the pump. A test light needs a lot more current to operate and will not light up if there's a break in that wire.

The alternative is to measure the voltage on that wire while it's still plugged in and the pump is drawing current, but that's not easy to do unless you can fashion a piece of wire for a test point.

The pump still should have run with an external battery.

Oops. Let me back up for a minute. When you turn on the ignition switch, you already heard those relays get powered for one second. That is done to run the fuel pump in case the pressure bled off overnight. I don't know about the 3.3L, but I do know from chasing an intermittent problem on my '88 with the 3.0L, that both engines run around 50 pounds of pressure, but my 3.0L still runs fine down to 20 pounds. (Some GM engines won't start if pressure is just two pounds low).

Once you start cranking the engine, pulses arrive from the cam and crank sensors. That is how the computer knows the engine is rotating, (cranking or running), and that is when it turns on those two relays. The fuel pump relay feeds only the fuel pump. The ASD relay feeds the ignition coil, or coil pack in your case, injectors, alternator field, oxygen sensor heaters, AND the fuel pump on older vehicles without a separate fuel pump relay. This is a safety circuit and it's real effective and reliable. If the vehicle is in a crash that ruptures a fuel line, raw fuel will get pumped onto the ground, and some people seem to think that's a fire hazard. The injectors can't spray fuel with no fuel pressure in that ruptured hose, so the engine stalls. When it stalls, there's no more pulses from the two sensors so the computer turns the ASD relay, (and the fuel pump relay) off. That stops the gas from being dumped on the ground.

I don't recall the computer monitoring the coil part of those two relays. It just grounds one terminal and assumes they turned on. There IS, however, another circuit coming off the ASD relay that, along with feeding the injectors and coil pack, goes back to a terminal at the computer. If no voltage shows up there, the computer can set a fault code related to the ASD relay not turning on, or that voltage is missing, or something like that. That circuit might supply other things inside the computer but it has nothing to do with the engine not running.

On the newer engines, as a point of interest, the engine will continue to run if one of the two sensors fails, but once it is stopped, it will crank but not restart. (There is a way to trick it into starting and running), but on this one the engine will stall if either signal is missing. The fact that the engine runs proves there's spark and the injectors are firing. That proves they're getting current from the ASD relay, so we know the computer is turning it on and the two sensors are working.

That brings us back to the fuel pump. GM pumps commonly fail while you're driving, leaving you sitting in the middle of nowhere on the side of the road. Chrysler pumps rarely if ever fail once they've started to run. They typically fail to start up. There's two causes for that. Most commonly, at high mileage, the brushes in the motor wear down and don't make good contact. The clues are that often a bang on the gas tank gets them going, you don't hear the hum for that one-second burst, and if you jump the relay or squeeze its contact, you won't see the normal tiny spark when you open the circuit. That's because there's no current flow, hence, no spark when you turn it off.

The second cause, which I eluded to earlier, has to do with repeat failures, usually from a week to a month apart. Many people buy a replacement pump from an auto parts store, and it works fine for a few weeks, then fails to start up. After four or five failures, out of frustration, they buy one from the dealer and don't have any more problems. In reality, the pumps weren't the problem. Unlike GM truck fuel pumps that you can hear a mile away, Chrysler pumps are built to very close tolerances to make them really quiet. Microscopic debris collects in the tank, (I suspect mold growth from using ethanol), and that debris clogs the impeller which locks up the motor. Each replacement pump collects a little more of that debris until finally it's all gone and the next pump won't fail. That one just happens to be from the dealer. As another point of interest, NAPA buys their fuel pumps for Chrysler products from the same supplier that makes them for Chrysler, so you're getting the same pump as the dealer's pump, and they're just as quiet. That may be true of other auto parts stores too but I only know that for sure about NAPA. The clue to this problem is you WILL see a spark when you jump the fuel pump relay but it won't blow a fuse. There's obviously current flow but the motor doesn't run. The fix for this was to remove the tank and have it steam-cleaned at a radiator repair shop. I haven't heard of this happening lately, possibly due to better additives in the gas today.

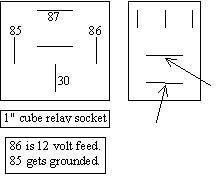

Getting back to your pump, jump the relay so you don't have to turn on the ignition switch or crank the engine to do the troubleshooting. Check for voltage at the pump on the dark green / black wire. If it's missing, there's two connectors between there and the relay that are good suspects. If you DO have voltage there, check on the black ground wire. If you have any voltage on that one, there's a break in it. You may be able to get a clue from watching the fuel gauge on the dash. The sending unit shares the pump's ground wire. If the gauge reads correctly with the ignition switch on, but changes during cranking, it has to be due to voltage on the ground wire.

Tuesday, January 14th, 2014 AT 3:35 AM