Hi bblasz,

Thank you for the donation.

Here are the procedures for removal of the bearing.

AXLE SHAFT

Removal

1. Secure axle shaft assembly in a vise, and remove one retainer bolt from backing plate. Push bearing case completely to side of dust cover. Place adhesive tape around edge of bearing case at retainer bolt hole to prevent damage.

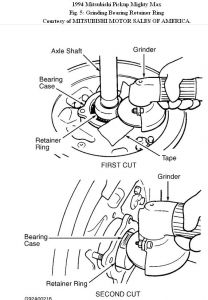

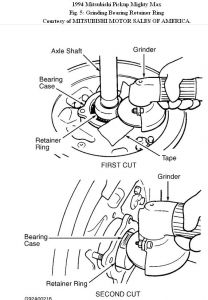

CAUTION:DO NOT damage bearing case or axle shaft when grinding or chiseling retainer ring.

2. Secure axle shaft, and grind retainer ring until retainer ring wall thickness is .04-.06" (1.0-1.5 mm) on axle shaft side and .08" (2.0 mm) on bearing side. See Fig. 5 .

3. Change angle of grind, and remove remaining .08" (2.0 mm) of retainer ring wall on bearing side. See

Fig. 5 . Using a chisel, cut retainer ring. Remove ring.

DO NOT damage axle shaft.

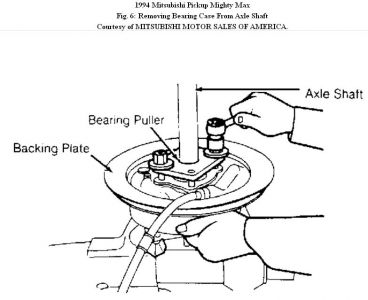

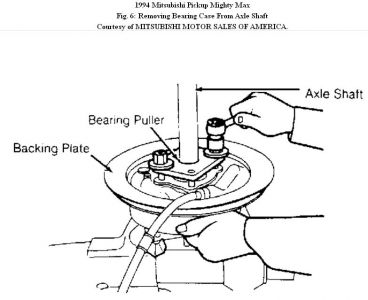

4. Install Puller (MB990787-01) to remove bearing case from axle shaft. See Fig. 6 . Rotate nuts with equal force to remove wheel bearing. Remove bearing outer race using a hammer and drift. Remove oil seal from axle housing using a slide hammer and hook.

Inspection

Inspect bearings for roughness, pitting or damage. Inspect axle shaft for damaged splines or flange. Inspect bearing case for cracks or damage.

Installation

1. Apply Multipurpose Grease (SAE J310) to oil seal, oil seal cavity and contact surfaces. Install oil seal using seal driver. Press new oil seal into bearing case until it is flush with face of bearing case. Install backing plate and bearing case.

2. Apply grease to external surfaces of bearing outer race. Press bearing outer race into bearing case. Install bearing on axle shaft. Install rear brake assembly with bearing case onto axle. Iinstall new retainer ring. Do not exceed 17,637 lbs. (80,000 N) when pressing on retainer ring. Install new snap ring.

3. Using a feeler gauge, measure clearance between snap ring and new retainer ring. Clearance should be less than .007" (.17 mm). If clearance exceeds specification, install correct snap ring.

If you do not have the puller, you can try this. After removal of the retainer ring, with a hard wooden block on a flat and sturdy surface, lift the axle with the backing plate on top and hammer the axle onto the wooden block.

The weight of the bearing housing and backing plate would enable the bearing to be slowly pushed outwards. Might require some hammering.

Friday, June 4th, 2010 AT 10:13 AM