Tuesday, May 14th, 2024 AT 7:10 AM

SPONSORED LINKS

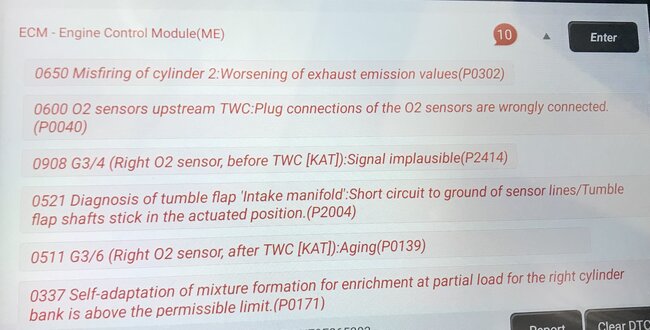

Misfiring bank 1?

6 Replies

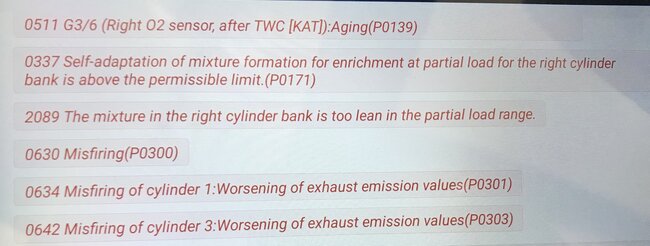

This will happen when the catalytic converter is clogged or has fallen apart, I would remove it for inspection, here is how. Check out the images (below). Please upload pictures or videos in your response to any problems so we can see what to help you with.

SPONSORED LINKS

Was this helpful?

Yes

No

Tuesday, May 14th, 2024 AT 12:11 PM

I did some more checking and found intake manifold tumble flap lever broken. That’s why it’s showing code P2004. Which is causing all the other codes. I found out this is a common problem on 272 engine. Can you send me information on how to remove intake manifold to replace this broken lever. Thanks.

Was this helpful?

Yes

No

Wednesday, May 15th, 2024 AT 1:58 PM

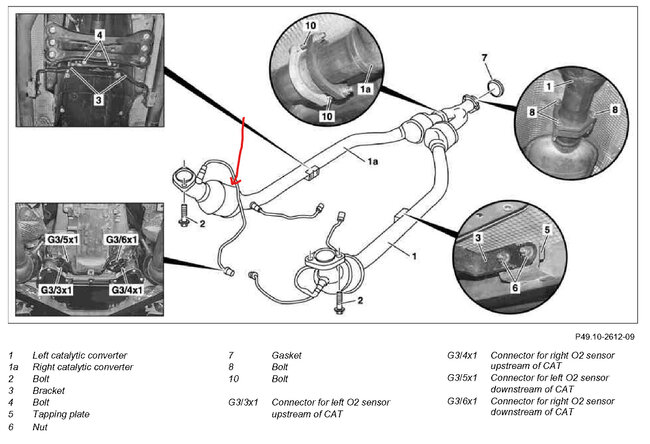

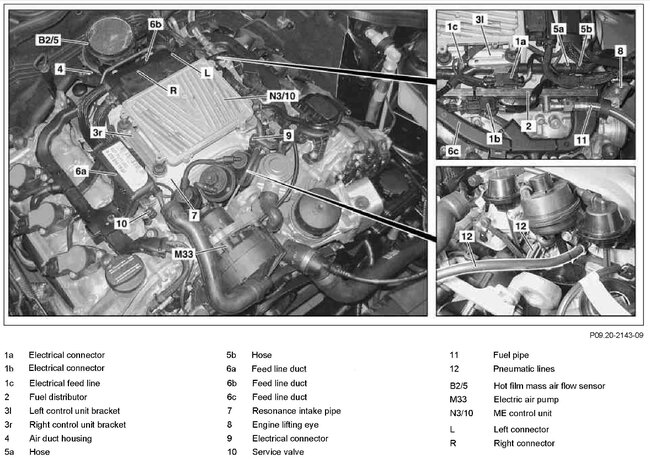

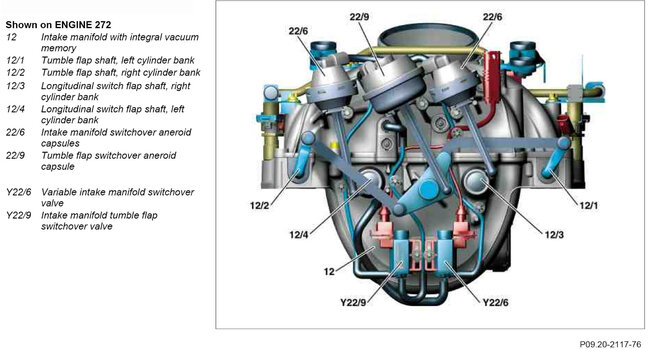

Yep, that happens as well, I should have mentioned it. Here is information on the tumble flap so you can get it fixed.

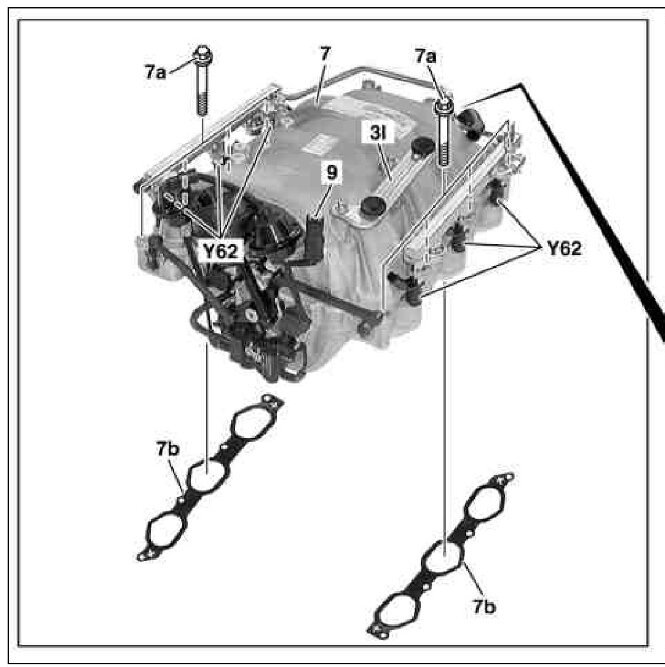

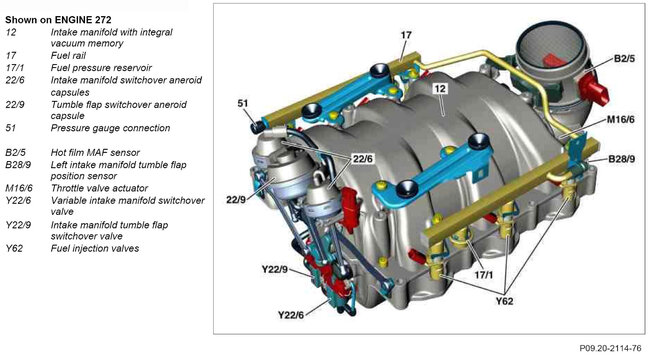

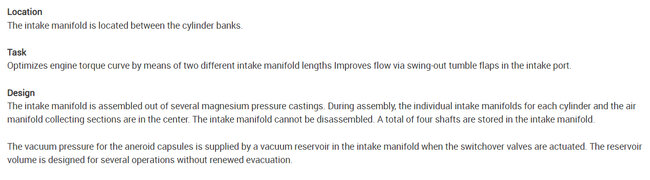

Intake manifold switchover, function

The individual intake manifolds each approx. 800 mm long, are arranged in a spiral shape around the air collecting volume. Each single intake manifold has a further opening to the air collecting volume somewhere in the middle. These can be opened or closed by rotating longitudinal switch flap shafts.

The switch flaps of a cylinder bank are interconnected by a shaft and each of the flap is actuated by an aneroid capsule in case of engine 272 BOTH aneroid capsules for the intake manifold switchover are connected to the variable intake manifold switchover valve via hose pipes. Engine 273 has only one aneroid capsule. The flap shafts are connected in the intake manifold. The switch flaps open by spring force without actuation and enable the short suction way

At higher speeds (from approx. 3500/min) the intake manifold switchover aneroid capsules are ventilated and the switch flaps opened by the spring force. The intake air takes the short intake route.

At lower speed (up to approx. 3500/min) the intake manifold aneroid capsules are pressurized with vacuum pressure and the longitudinal switch flaps closed. The intake air takes the long intake route. The result is improved cylinder charge and thus an increase in torque.

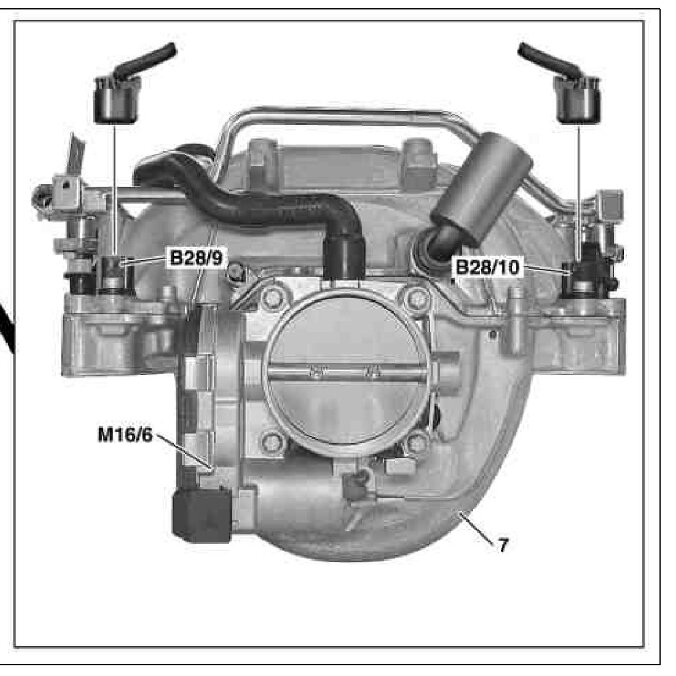

Tumble flap switchover function

At partial load, tumble flaps can be fully swung out in each cylinder intake port in the intake manifold. This closes the intake manifold by around 50 %.

The flow speed of the intake air is increased and allows for improved distribution of the fuel/air mixture in the combustion chamber. The tumble flaps are actuated via an aneroid capsule and linkage.

Check out the images (below). Let us know if you need anything else.

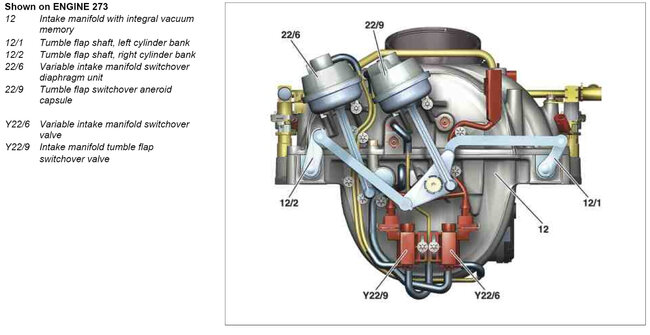

Intake manifold switchover, function

The individual intake manifolds each approx. 800 mm long, are arranged in a spiral shape around the air collecting volume. Each single intake manifold has a further opening to the air collecting volume somewhere in the middle. These can be opened or closed by rotating longitudinal switch flap shafts.

The switch flaps of a cylinder bank are interconnected by a shaft and each of the flap is actuated by an aneroid capsule in case of engine 272 BOTH aneroid capsules for the intake manifold switchover are connected to the variable intake manifold switchover valve via hose pipes. Engine 273 has only one aneroid capsule. The flap shafts are connected in the intake manifold. The switch flaps open by spring force without actuation and enable the short suction way

At higher speeds (from approx. 3500/min) the intake manifold switchover aneroid capsules are ventilated and the switch flaps opened by the spring force. The intake air takes the short intake route.

At lower speed (up to approx. 3500/min) the intake manifold aneroid capsules are pressurized with vacuum pressure and the longitudinal switch flaps closed. The intake air takes the long intake route. The result is improved cylinder charge and thus an increase in torque.

Tumble flap switchover function

At partial load, tumble flaps can be fully swung out in each cylinder intake port in the intake manifold. This closes the intake manifold by around 50 %.

The flow speed of the intake air is increased and allows for improved distribution of the fuel/air mixture in the combustion chamber. The tumble flaps are actuated via an aneroid capsule and linkage.

Check out the images (below). Let us know if you need anything else.

Was this helpful?

Yes

No

Thursday, May 16th, 2024 AT 11:04 AM

Related Engine Misfire Content

Sponsored links

SPONSORED LINKS

Intermittent Misfire

How to Repair an Engine Cylinder Misfire