Hi guys. You're right about throwing good money after bad, but that is exactly what you're describing. We call that "replacing random parts" in hopes one will magically solve the problem. That is the least effective way and the most expensive way to diagnose the cause of a problem. It will be faster and less expensive to have it diagnosed by a professional.

I have four of these vans including a '94 and a '95, with the 3.3L engine. There are multiple ways a MAP sensor can fail, and not every way sets a fault code. That's why you were told to put a new one on. One clue you can look for is with the most common failure, the engine will start, then stall within a few seconds. You can keep the engine running by moving the accelerator pedal. Doesn't matter how fast, how far, or which direction. It just can't sit in one spot. I surprised a lot of owners who had their vans towed to the dealership for not running, yet I was able to start them up and drive them into the shop.

That type of failure was traced to over-filling the gas tank, then immediately parking the vehicle in hot weather. Fumes in the tank would expand and migrate through the vacuum system to the MAP sensor where it would deteriorate the protective jell over the "piezoelectric crystal" sensing element. That's the same thing that was used in low-cost record player needles years ago. GM designed that sensor, had a huge rash of failures, then sold them to Chrysler. Those are all gone now. GM redesigned them with a sensing element called a "strain gauge". It's basically a very long, thin wire wrapped around a flexible core that's connected to a vacuum diaphragm. Those have been very reliable.

You can also have a failure of the sensor's internal circuitry. Depending on what fails, it could report an incorrect value, but as long as it is within the acceptable limits, the Engine Computer will accept it and not set a fault code. That can be an elusive diagnosis, but that almost always turns into a total failure within a few days.

The MAP sensor is fed with 5.0 volts and ground, then the acceptable range of signal voltage is 0.5 to 4.5 volts, give or take. A failure has to cause the signal voltage to go outside those limits, then that is what the computer sees to set a fault code.

With another type of failure, all the electrical circuitry is fine, but there's a crack in a dry-rotted vacuum hose. The sensor will report low vacuum which equates to heavier acceleration, and the need for more fuel. The tip-off is usually a fault code related to MAP pneumatic fault", meaning the vacuum system. While they don't do it, these sensors are sensitive enough that they could use them to measure engine speed by counting the very slight increases in vacuum each time a cylinder takes a gulp of air. A couple hundredths of a volt change means a lot to the Engine Computer.

That's also why you can't test a MAP sensor. The only thing you can do is use a digital voltmeter to measure the signal voltage. It will be high with the engine not running and the ignition switch in "run". That is measuring barometric pressure which gets put in memory for that drive cycle. As soon as the engine starts and vacuum is developed, the signal voltage will drop considerably. That's all you can do is see if that change occurs. There's no way to know if the reading should be 2.67 volts, 2.69 volts, or 3.92 volts. Only the Engine Computer can look at the voltages and interpret them to see if they're correct, then you need a scanner to talk back and forth to the Engin Computer so it can tell you what it's seeing and reacting to.

Professionals might measure that signal voltage, but only to confirm the rest of the circuitry is working properly, before spending a customer's money on the new sensor. Given there's so little you can do yourself, and given most people don't have a $5000.00 scanner, the logical choice is to pop in a new sensor. If it doesn't solve the problem, put the new one in the glove box until you do need it.

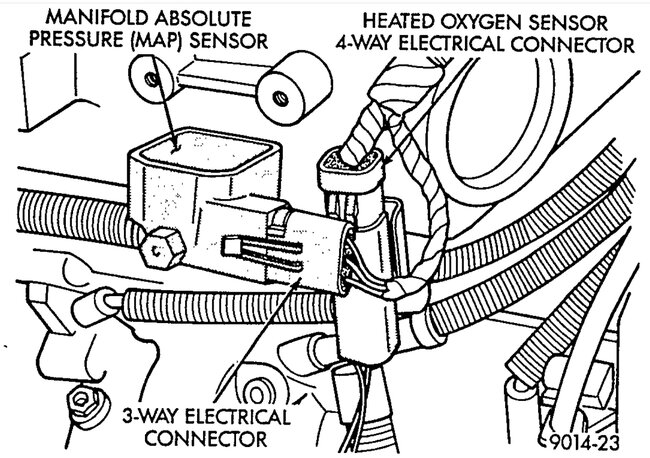

By the way, you've seen your MAP sensor is screwed into the intake plenum. They did that to eliminate the dry-rotted vacuum hose. Before that, they could also set a pneumatic fault code if the vacuum hose was blocked, most commonly by condensed gas fumes. Vacuum was still measured correctly, but the computer didn't see those little pulses of increased vacuum each time a piston drew in air. The vacuum pulses got damped by the liquid and didn't show up at the sensing element. That's how the computer knew there was partial blockage in the vacuum hose.

Ken has already asked you if there are any other fault codes. Crank / no-start conditions are much more commonly caused by a failed crankshaft position sensor or camshaft position sensor. On your engine, both signals must be present for the computer to turn on the automatic shutdown, (ASD) relay that sends current to the ignition coils and injectors. The clinker with those sensors is the computer needs a little time to detect the missing signal from either one of them. For that reason, you may not get a fault code just from cranking the engine. So don't assume both sensors are okay just because there's no code set for them. We use the live data function on the scanner to let the computer tell us whether one of the signals is missing. You can start the diagnosis yourself by simply checking if you have spark. When the ASD relay isn't getting turned on, you will be missing spark AND injector pulses, so don't get hung up on the first thing you find missing. The fuel pump won't be running either. I can elaborate a lot more on those issues if it becomes necessary. For now, you can use a voltmeter, but a test light is the better choice as most voltmeters don't respond fast enough. Probe the wire that is the same color at every ignition coil and every injector. That should be a dark green with an orange stripe, or "tracer".

Have a helper turn on the ignition switch. You'll see the test light turn on for one second, then go back off. What is important is it must turn on again as soon as the engine starts rotating, (cranking or running). If it doesn't turn back on during cranking, the no-start has nothing at all to do with the MAP sensor.

For my final comment of value, I would like you to be aware that diagnostic fault codes never ever tell you to replace a part or that one is defective. They only indicate the circuit or system that needs further diagnosis, or the unacceptable operating condition. When a sensor or other part is referenced in a fault code, it is actually the cause of that code about half of the time. This is where we have to check for wiring and connector terminal problems, or mechanical issues related to that part first. In spite of that when you don't have any other resources available, we do approve of just tossing in the new sensor as a test.

Hope that sheds a little light on the problem. I watch on the side to see if you need more of my wondrous wisdom.

Friday, July 12th, 2024 AT 10:26 PM