Torque wrenches aren't specific to which axle you have. The best approach is to get a copy of the manufacturer's service manual. They will show pictures of the covers to identify which axle you have. On the last few pages of each section they will list the special tools with their part numbers and line drawings to show what they look like. You won't need all of those tools. Some are included in the kits all dealers are forced to buy, but we can often do the job without them. You can make some tools too.

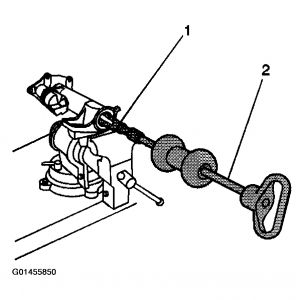

I used to work for a very nice family-owned Chrysler dealership. We were allowed to borrow special tools to good customers. In this case, some axle housings need a spreader to stretch it so the center section can be lifted out. You may need shims and gauges to adjust the tooth contact pattern. If you're replacing the collapsible spacer on the shaft of the pinion gear, good luck! You'll need a long tool that bolts to the u-joint strap holes to hold the pinion gear from spinning, then you'll need a huge wrench to tighten that nut. Doing that is almost impossible unless the vehicle is on a hoist or the axle housing is out of the vehicle.

You'll need a really large torque wrench for that pinion nut. A cheap torque wrench is okay for this type of job. There's nothing wrong with tools from Harbor Freight Tools, Sears, and places like that. I'm not sure I would trust them for critical adjustments like for engine cylinder heads, but for an axle, if you're off by 5%, your world will not come apart. A cheap torque wrench will still give pretty good consistency from one bolt to the next. Where they fall down on the job is, for example, they might be right on the money at 100 foot-pounds, but when you dial up 150 foot-pounds, you might get it to click at 145 or 155 foot-pounds. In other words, they might only be accurate at one or two settings. The expensive torque wrenches that professionals buy from the guys who visit shops with their tool trucks each week will be accurate at any setting, but you have to need this tool a lot to justify that higher cost.

Don't even think about buying a beam-type torque wrench with the scale and pointer. You won't find one big enough, and consistency is compromised by how well your vibrating eyes can read it while your arm is shaking from tugging on it so hard. Only consider a click-type torque wrench. Always dial them down to "0" when they're not being used to prevent weakening the spring.

SPONSORED LINKS

Thursday, February 25th, 2021 AT 10:08 AM

(Merged)