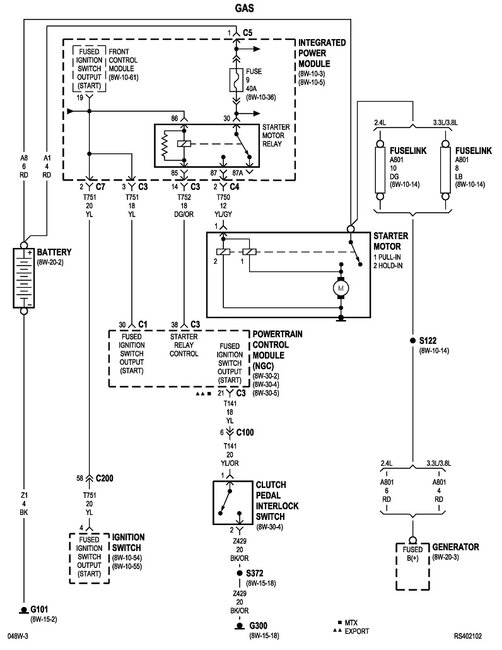

Before we get all "wrapped around the axle", there's a number of better things to consider. First, you were on the right track to check for fuel and ignition, but there won't be 12 volts to the ignition coil(s), injectors, and fuel pump or fuel pump relay just by turning on the ignition switch. To have 12 volts all the time would make a major fire hazard possible if a fuel line was ruptured in a crash. Instead, connect a test light to the wire that is the same color at the ignition coil pack or any injector, and set it so you can see it from the driver's seat, or have a helper turn the ignition switch for you. On your van that will be a brown / white wire.

A test light works best for this because most digital voltmeters don't respond fast enough. The test light should light up full brightness for one second when the ignition switch is turned on. That proves the automatic shutdown, (ASD) relay and its circuits are working. Next, the test light should turn on again during engine rotation, (cranking or running). If it does not, we have to look at the crankshaft position sensor and the camshaft position sensor. The Engine Computer needs to see steady signal pulses from them to know when to turn on the ASD relay.

You should be able to crank the engine three times when it fails to start. After that, the computer locks the system for a short time. I can't remember how long you have to wait, but as I recall, it's minutes, not hours.

If everything is okay up to this point, I have a suspicion you disconnected the battery during the recent repairs. If you did, it's almost a certainty the failure to run is due to low idle speed. To prove that, hold the accelerator pedal down 1/4" when you crank the engine. If that works, the engine is likely to quit again when you release the pedal. Low idle speed causes the failure to start, and a tendency to stall at stop signs. The solution is real simple. When the battery is reconnected, the computer relearns the personalities of the sensors right away. Fuel trim numbers are relearned as soon as you start driving, without you even noticing. The one huge exception is "minimum throttle". Until that is relearned, the computer won't know when it has to be in control of idle speed.

To meet the conditions for the relearn to take place, use two feet on the pedals if necessary, drive at highway speeds with the engine warmed up, then coast for at least seven seconds without touching the pedals.

The relearn will be cancelled if either pedal moves. If the relearn doesn't occur, it might be due to the brake pedal bouncing on rough roads. There's three separate circuits in the brake light switch, so you are likely to not see the brake lights flicker on bumpy roads, but the switch can still prevent the relearn from taking place. To check for that, do the coasting procedure while holding the brake pedal up with your foot. If that works, there are usually other unrelated symptoms at the same time, most notably, the cruise control turning off on rough roads.

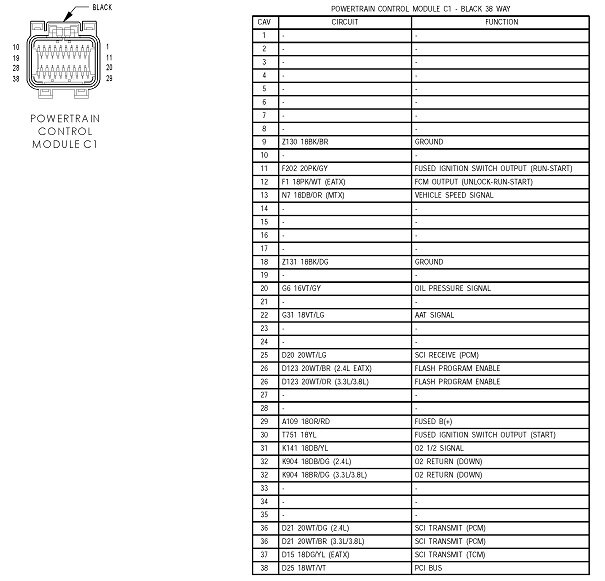

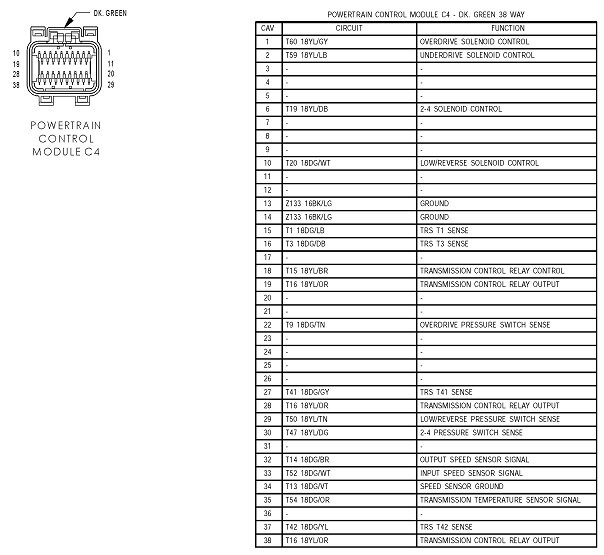

See how far this gets you. I'll work on formatting the connector views for uploading in case you still need them.

Saturday, November 23rd, 2024 AT 8:35 PM